Nano cellulose/aramid fiber nano fiber membrane composite nano paper and preparation method thereof

A nanocellulose and nanofiber membrane technology, applied in special paper, fiber raw material processing, non-fiber pulp addition, etc., can solve the problems of weak UV shielding, poor thermal stability, low wet strength, etc., and achieve excellent UV shielding and Anti-aging properties, good temperature resistance, the effect of improving wet strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of nanocellulose / aramid nanofiber membrane composite nanopaper, comprising the following steps:

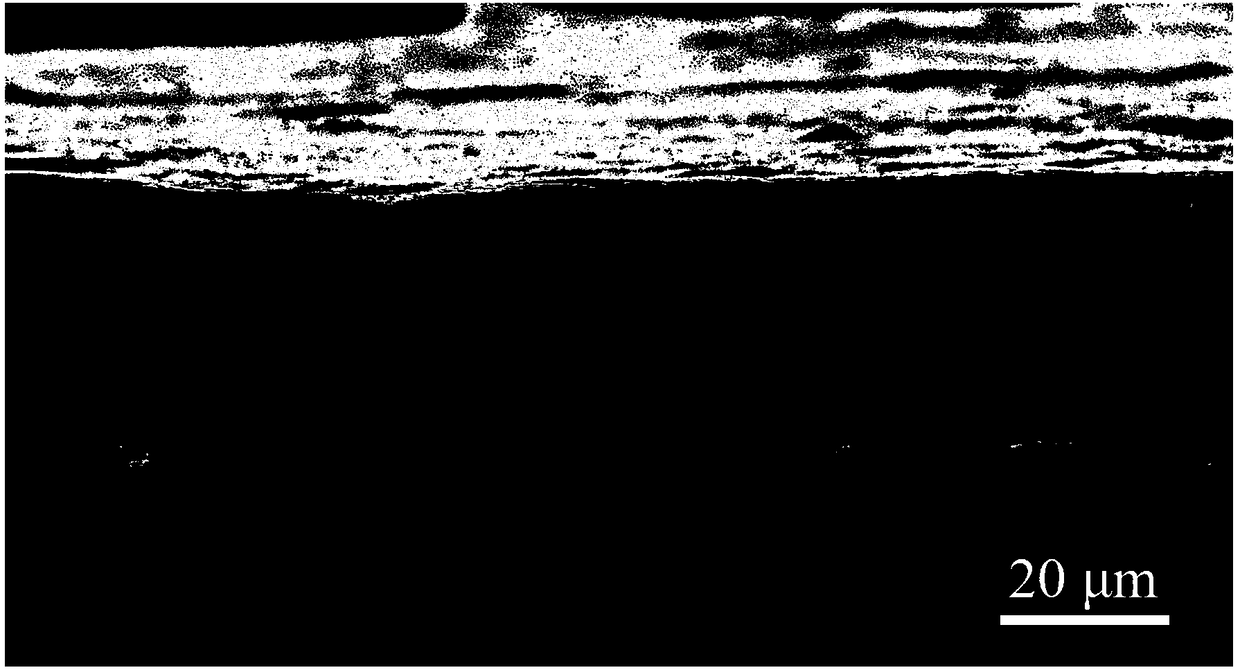

[0029]Step 1: Using bleached softwood kraft pulp board as raw material, prepare nanocellulose by TEMPO (2,2,6,6-tetramethylpiperidine-nitrogen-oxide) oxidation method, and then dilute with water to a mass concentration of 0.05% to 0.5% nanocellulose dispersion; the diameter of the nanocellulose in the nanocellulose dispersion is 20 to 30 nm; the obtained nanocellulose dispersion is dehydrated on a filter with a mesh number of 300 Shaping and drying at 80-105°C for 7-15 minutes to obtain nanocellulose nanopaper, which is denoted as CNF nanopaper; the quantification of the CNF nanopaper is 20-50g / m 2 , with a thickness of 20-50 μm.

[0030] Step 2: Using para-aramid chopped fibers as raw materials, aramid nanofiber dispersion is prepared in a mixed solution system of potassium hydroxide and dimethyl sulfoxide; in the aramid nanofiber dispersion, aramid n...

Embodiment 1

[0036] A nanocellulose / aramid nanofiber membrane composite nanopaper, the composite nanopaper is composed of nanocellulose nanopaper impregnated with polydimethyldiallylammonium chloride and aramid nanofiber membrane The composite nano paper has a multi-layer structure, wherein the nanocellulose nano paper impregnated with polydimethyldiallylammonium chloride is the matrix, and the aramid fiber nanofiber dispersion is formed by protonation reduction The nanomembrane is combined with the nanocellulose nanopaper matrix through layer-by-layer self-assembly; the quantitative amount of the nanocellulose nanopaper is 20g / m 2 , with a thickness of 20 μm; the number of composite layers of the aramid nanofilm is 1 layer;

[0037] A preparation method of nanocellulose / aramid nanofiber membrane composite nanopaper, comprising the following steps:

[0038] Step 1: Using bleached softwood kraft pulp board as raw material, prepare nanocellulose by TEMPO (2,2,6,6-tetramethylpiperidine-nitro...

Embodiment 2

[0042] A nanocellulose / aramid nanofiber membrane composite nanopaper, the composite nanopaper is composed of nanocellulose nanopaper impregnated with polydimethyldiallylammonium chloride and aramid nanofiber membrane The composite nano paper has a multi-layer structure, wherein the nano cellulose nano paper impregnated with polydimethyldiallylammonium chloride is aramid nanofiber dispersion formed by protonation reduction The film is combined with the nanocellulose nanopaper impregnated with polydimethyldiallylammonium chloride through layer-by-layer self-assembly; the quantitative weight of the nanocellulose nanopaper substrate is 25g / m 2 , with a thickness of 25 μm; the number of composite layers of the aramid nanofilm is 3;

[0043] A preparation method of nanocellulose / aramid nanofiber membrane composite nanopaper, comprising the following steps:

[0044] Step 1: Using bleached softwood kraft pulp board as raw material, prepare nanocellulose by TEMPO (2,2,6,6-tetramethylp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com