Inhibitor and ore dressing method of high-sulfur refractory copper and sulfur ore

A beneficiation method and technology for sulfur ore, applied in flotation, solid separation and other directions, can solve the problems of large consumption, adverse effects of copper recovery, difficult to suppress, etc., to reduce high alkalinity pressure, improve comprehensive utilization rate, and suppress effect. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

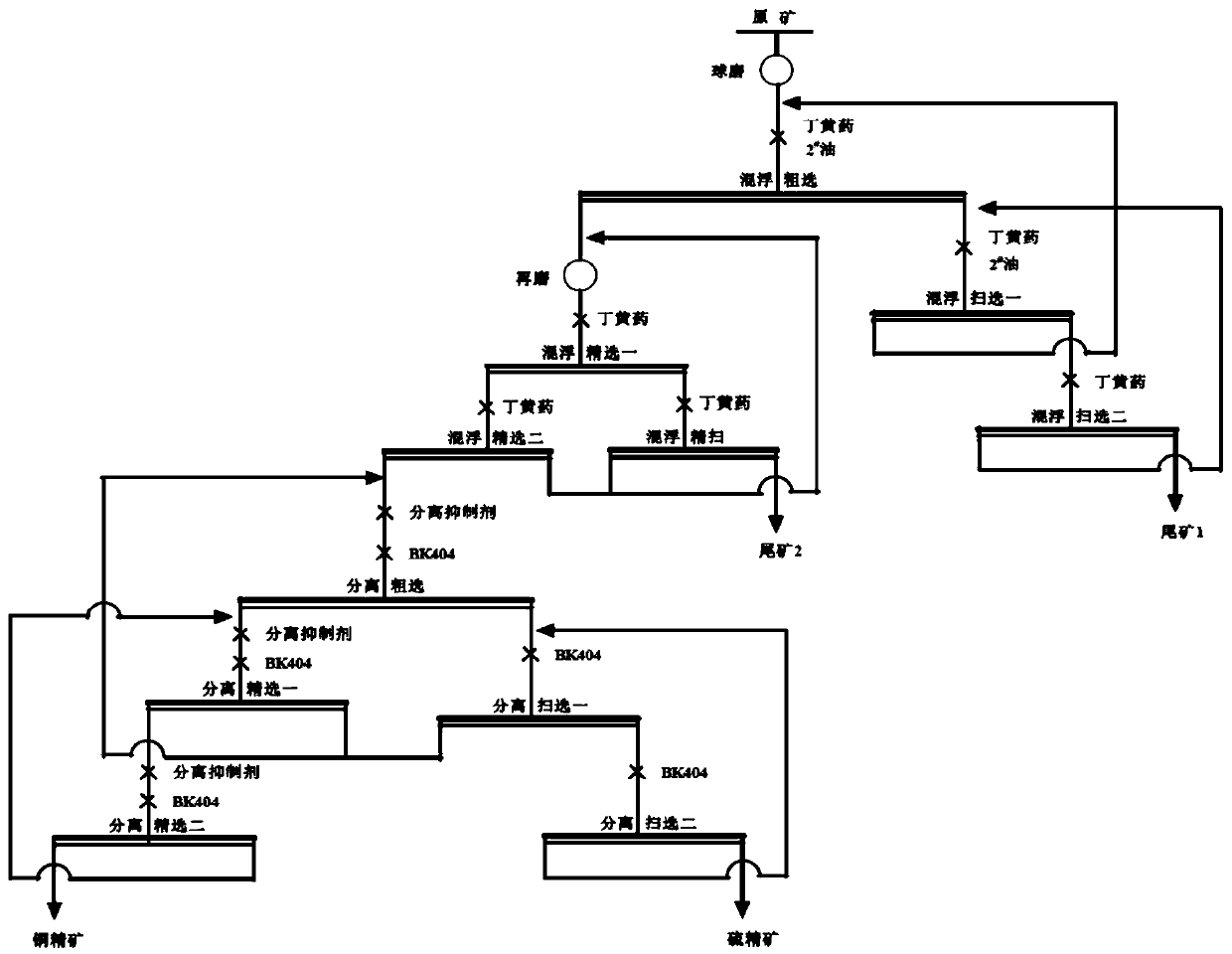

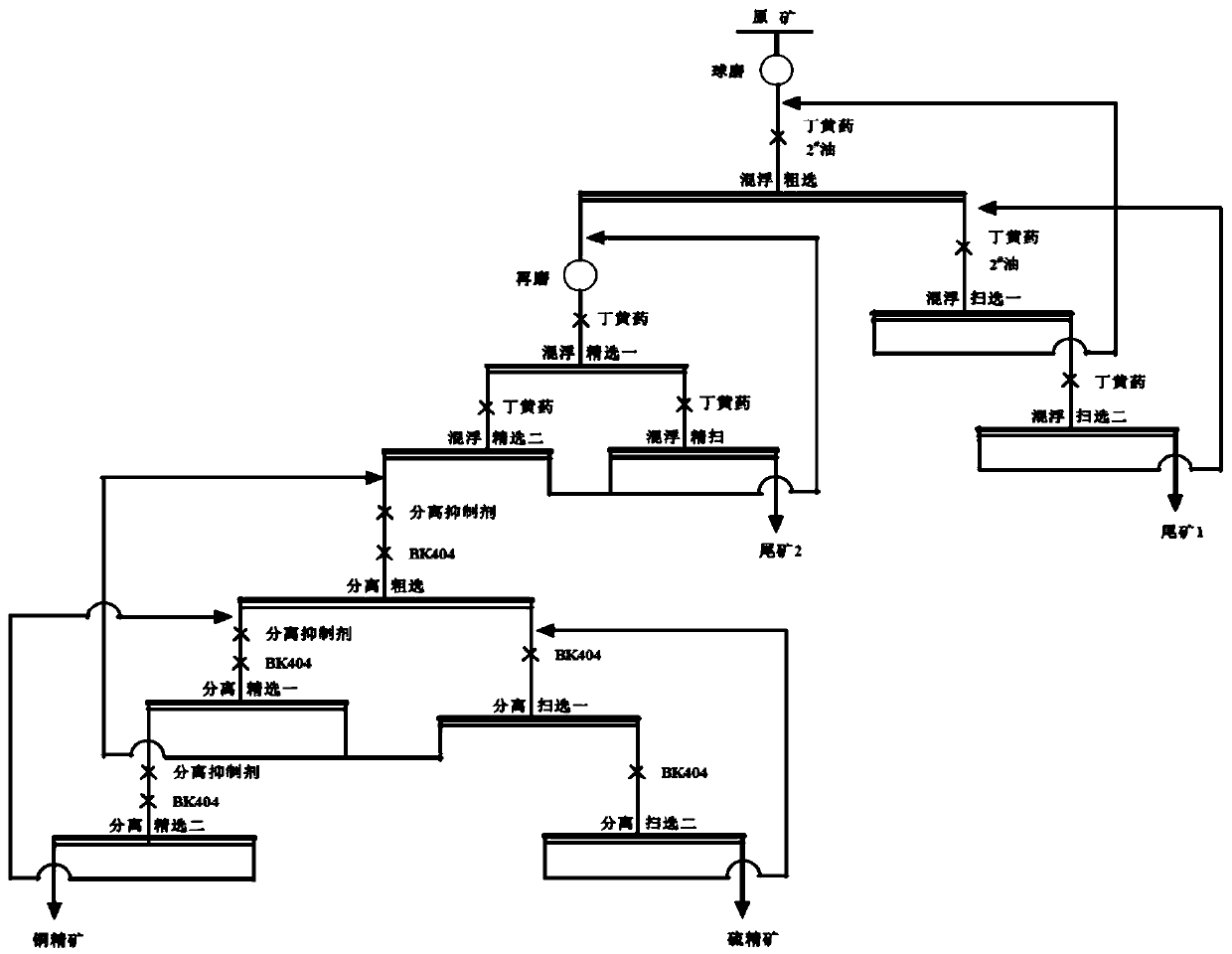

[0019] Inhibitor and mineral processing method of high-sulfur refractory copper-sulfur ore of the present invention, its preferred embodiment is:

[0020] The inhibitor of high-sulfur refractory copper-sulfur ore is mixed with lime and sodium hexametaphosphate, and its mass ratio is: lime: sodium hexametaphosphate = 2.0-4.0:0.2-0.6.

[0021] The beneficiation method of high-sulfur refractory copper-sulfur ore comprises the following steps:

[0022] A. The steps of mixing and floating gangue after mixing coarse concentrate and regrinding:

[0023] Concentrate and dehydrate the copper-sulfur mixed coarse concentrate, then regrind through a wet ball mill, add butyl xanthate to the regrind mixed coarse concentrate slurry, select to obtain copper-sulfur mixed concentrate, and fine sweep to obtain the following Gangue mineral-based tailings II;

[0024] B. Steps for separation of mixed concentrate copper and sulfur:

[0025] Add the above-mentioned inhibitor and BK404 to the copp...

Embodiment 1

[0035] The raw ore of a copper-sulfur ore dressing plant in Anhui contains 0.85% Cu and 15.23% S. Copper minerals mainly exist in the form of chalcopyrite, with trace amounts of bornite, copper blue, tetrahedrite and chalcocite; most of the sulfur minerals are marcasite, pyrite and pyrrhotite; Iron minerals are mainly siderite, followed by magnetite, hematite and trace limonite. The gangue minerals are mainly quartz, followed by chlorite, plagioclase and kaolinite, and a small amount of calcite, orthoclase, dolomite, muscovite, biotite, apatite and trace amounts of talc.

[0036] Adopt the present invention to carry out ore dressing to this raw ore, its concrete steps are as follows:

[0037] (1) Raw ore grinding: Grinding the raw ore through a wet ball mill until the ore with a particle size of no more than 0.074mm accounts for 78% of the total ore weight, stop the grinding, and make a raw ore pulp with a mass concentration of 33%;

[0038] (2) Copper-sulfur mixed flotation...

Embodiment 2

[0047] A copper-sulfur polymetallic mine in Fujian contains 0.87% Cu and 12.09% S. The useful minerals are mainly chalcopyrite, pyrite and molybdenite, and a small amount of other metal minerals, such as chalcopyrite, galena, magnetite ore, hematite, limonite, siderite and pyrrhotite, etc.; there are many kinds of gangue minerals, mainly garnet, quartz and calcite, followed by pyroxene and chlorite, and a small amount of actinolite , hornblende, dolomite, feldspar and mica, etc.

[0048] The ore is beneficiated by the present invention, and the beneficiation results are as follows: by weight percentage, the finally obtained copper concentrate contains 21.66% of Cu, and the Cu recovery rate is 86.57%; the sulfur concentrate contains 51.15% of S, and the S recovery rate is 85.92%.

[0049]The raw ore is beneficiated using the existing similar technology, and the beneficiation results are as follows: by weight percentage, the obtained copper concentrate contains 19.23% Cu, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com