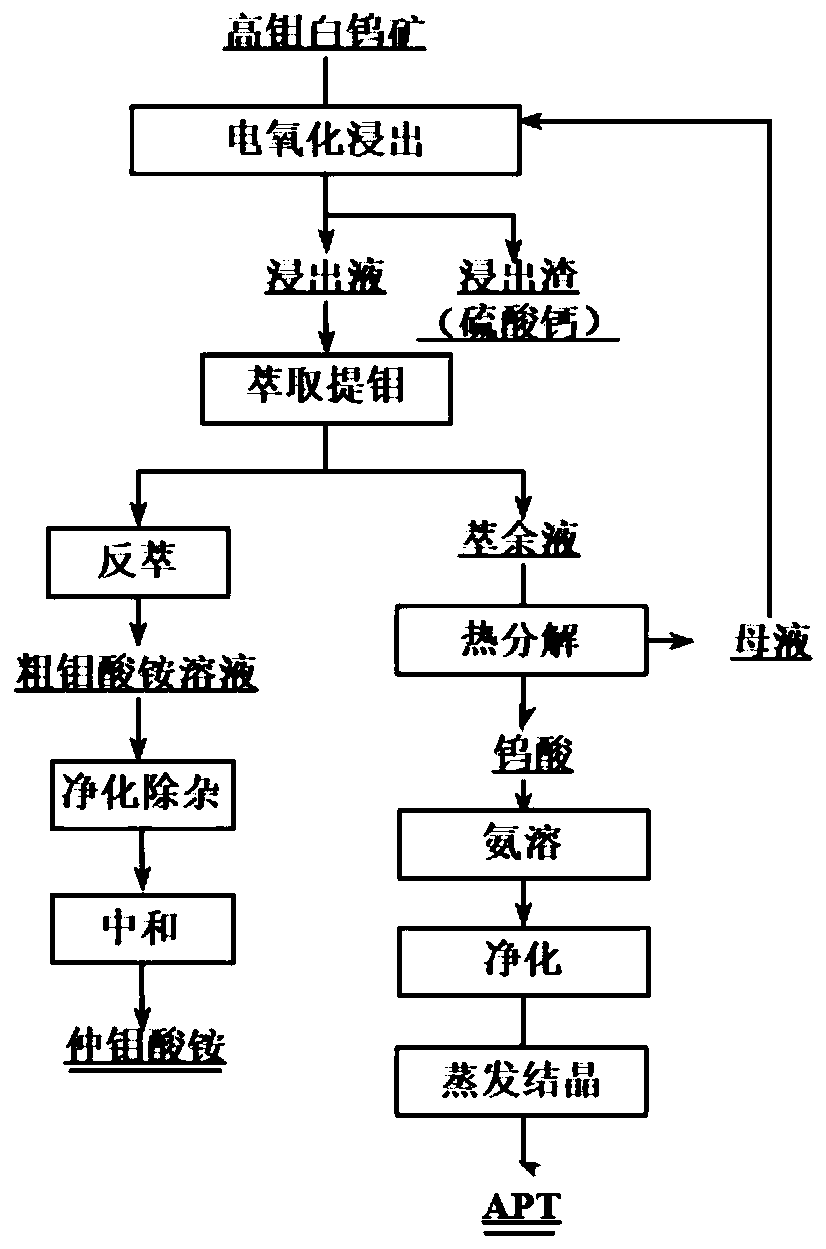

Method for extracting tungsten and molybdenum by decomposing high-molybdenum scheelite by electro-oxidation method

A technology of scheelite and electro-oxidation, applied in the direction of improving process efficiency, etc., can solve problems such as harsh working environment, waste of chemical raw materials, hindered reaction, etc., and achieve the effects of overcoming impact, reducing burden, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

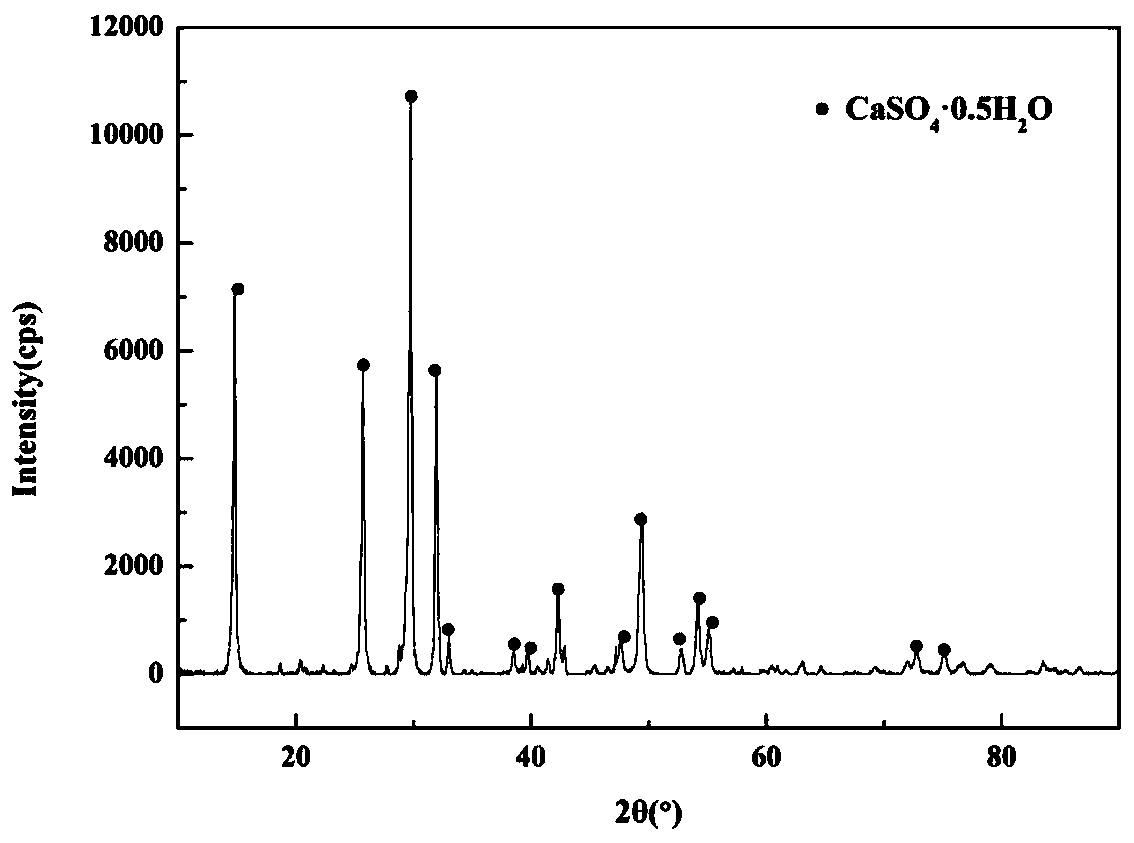

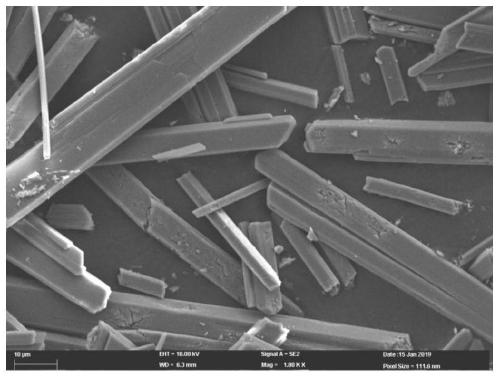

[0024] Scheelite (containing WO 3 51%, Mo 3.2%) was added to the sulfuric acid solution for electrooxidation leaching, and the H 2 SO 4 The concentration is 20%, the electrolysis temperature is 50°C, the reaction time is 3h, the liquid-solid ratio of the slurry is 8:1, the leaching rates of tungsten and molybdenum are divided into 98.3% and 98.4%, and after filtering and washing, the filter cake is washed with pure water three times to obtain the leaching residue. Characterize it, XRD figure and SEM picture are as follows figure 2 , as shown in 3. The filtrate uses 35% TBP+65% sulfonated kerosene, and extracts molybdenum according to O / A=1. The extraction rate of molybdenum is 93.8%, and the extraction rate of tungsten is 1.05%. The loaded organic phase is back-extracted with ammonia water to obtain a crude ammonium molybdate solution. The raffinate was thermally decomposed at 90°C, and the precipitation rate of tungsten was 99.1%. The XRD and SEM spectra of the product a...

Embodiment 2

[0026] Scheelite (containing WO 3 45%, Mo 2.5%) into the sulfuric acid solution for electro-oxidation leaching, control H 2 SO 4 The concentration is 25%, the electrolysis temperature is 55°C, the reaction time is 3h, the slurry liquid-solid ratio is 7:1, the leaching rates of tungsten and molybdenum are 98.8% and 98.6%, and the filter cake is washed three times with pure water after filtration and washing to obtain leaching residue. The filtrate uses 35% N235+65% sulfonated kerosene to extract molybdenum according to O / A=2, the extraction rate of molybdenum is 94.9%, and the extraction rate of tungsten is 1.5%. The raffinate is thermally decomposed at 95°C, and the precipitation rate of tungsten is 99.2%. The mother liquor is added with sulfuric acid and hydrogen peroxide to the initial concentration and then returns to leaching. The powdery tungstic acid obtained by thermal decomposition is subjected to ammonia dissolution-impurity removal-evaporation crystallization to o...

Embodiment 3

[0028] Scheelite (containing WO 3 45%, Mo 2.5%) into the sulfuric acid solution for electro-oxidation leaching, control H 2 SO 4 The concentration is 25%, the electrolysis temperature is 55°C, the reaction time is 3h, the liquid-solid ratio of ore slurry is 7:1, the leaching rates of tungsten and molybdenum are divided into 99.2% and 99.1%, and the filter cake is washed three times with pure water after filtration and washing to obtain leaching residue. The filtrate uses 35% TBP+65% sulfonated kerosene, O / A=1:2 to extract molybdenum, the extraction rate of molybdenum is 94.8%, and the extraction rate of tungsten is 1.2%. The loaded organic phase is back-extracted with ammonia water to obtain crude ammonium molybdate solution . The raffinate was passed through SO at 40°C 2 Gas, the precipitation rate of tungsten is 99.0%, and the mother liquor is added with sulfuric acid and hydrogen peroxide to the initial concentration and then returns to leaching. The powdery tungstic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com