Corrosion-resistant coating material for navigation marks and preparation method of material

A corrosion-resistant and coating technology, applied in the field of coatings, can solve the problems of limited adhesion to the dense substrate of the coating, unsatisfactory effect, limited water and oil repellency, water resistance and corrosion resistance of the coating, and achieve surface adsorption. Strong strength, strong adhesion and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

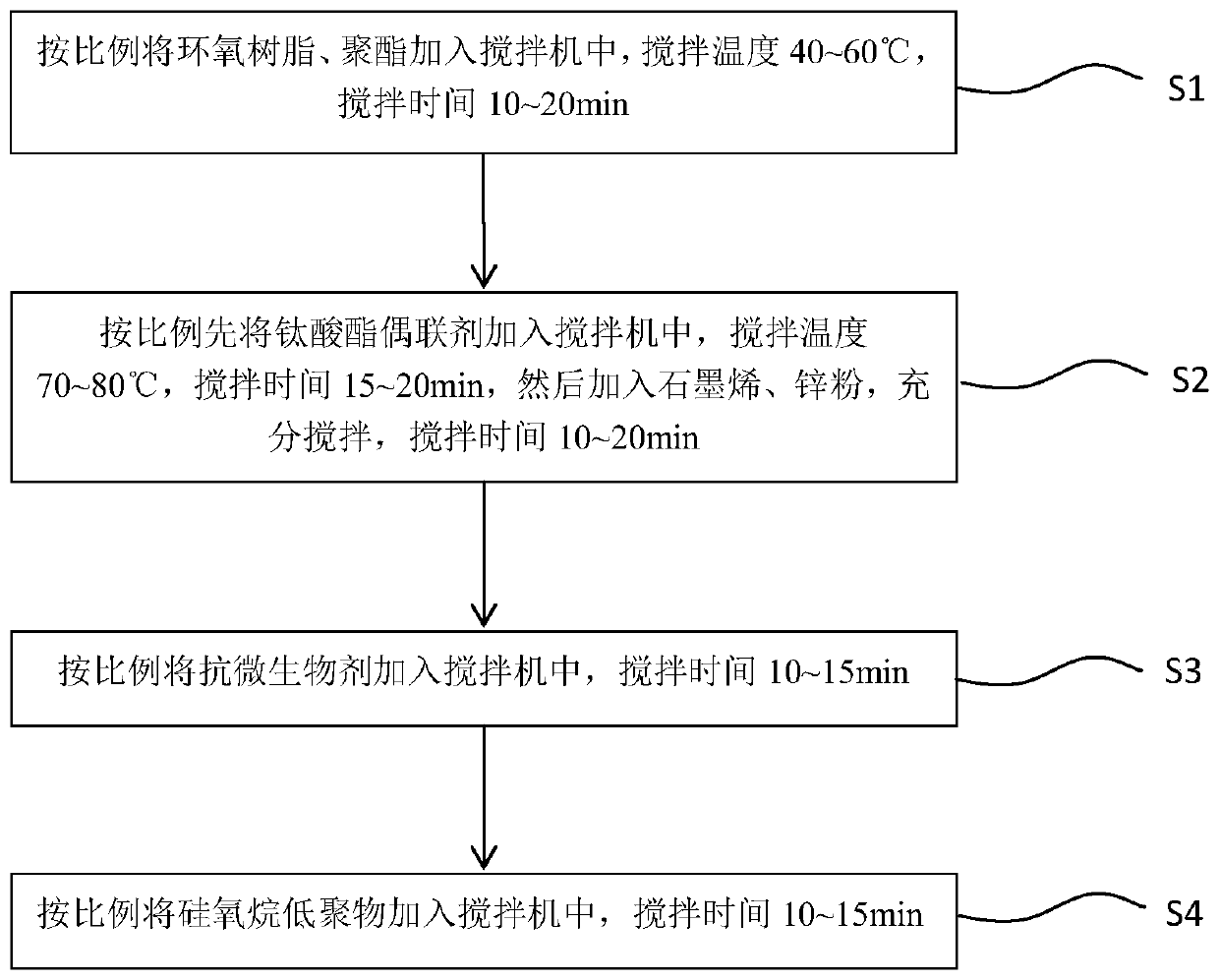

Method used

Image

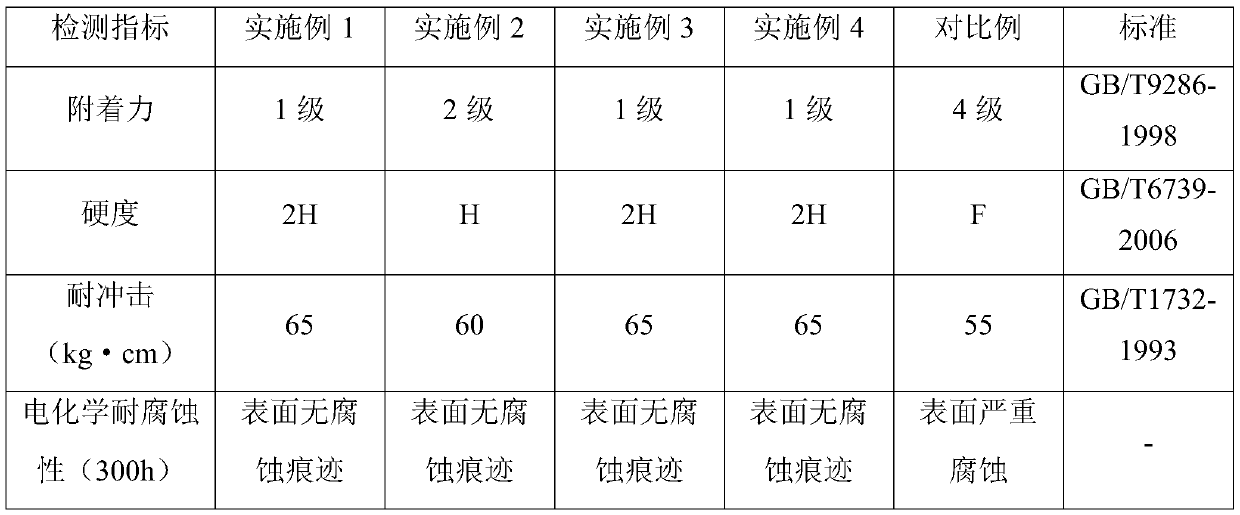

Examples

Embodiment 1

[0035] A kind of corrosion-resistant paint for navigation mark, its raw material comprises by weight: 32 parts of epoxy resin, 14 parts of polyester, 3 parts of coordination type titanate coupling agent, 15 parts of graphene, 10 parts of zinc powder, 35 parts of siloxane oligomer, 12 parts of antimicrobial agent tetrachloroisophthalonitrile, graphene is a micro-sheet powder structure with a thickness of 3 μm and a diameter of 6 μm, and zinc powder is a scaly structure with an average diameter of 2 μm .

[0036] Wherein, the preparation steps of siloxane oligomer are as follows:

[0037] (1) Manganese oxide is added to the aqueous solution containing glacial acetic acid, and then silica sol is added to prepare a mixed aqueous solution;

[0038] (2) Weigh and mix methyltrimethoxysilane and isopropanol according to the mass percentage of 1:1 to prepare a silanol solution;

[0039] (3) Under the condition of slow stirring, add the silanol solution prepared in step (2) to the mix...

Embodiment 2

[0046]A kind of corrosion-resistant coating for navigation mark, its raw material comprises by weight: 24 parts of epoxy resin, 22 parts of polyester, 1 part of titanate coupling agent, 6 parts of graphene, 20 parts of zinc powder, siloxane 45 parts of oligomers, 4 parts of antimicrobial agent diiodomethyl-p-tolylsulfone, graphene has a micro-sheet powder structure with a thickness of 8 μm and a diameter of 9 μm, and zinc powder has a scale-like structure with an average diameter of 9 μm.

[0047] Wherein, the preparation steps of siloxane oligomer are as follows:

[0048] (1) Calcium oxide is added to the aqueous solution containing acetic acid, and then silica sol is added to prepare a mixed aqueous solution;

[0049] (2) Weigh and mix methyltrimethoxysilane and isopropanol according to the mass percentage of 1:1 to prepare a silanol solution;

[0050] (3) Under the condition of slow stirring, add the silanol solution prepared in step (2) to the mixed aqueous solution prepa...

Embodiment 3

[0057] A kind of anti-corrosion coating for navigation mark, its raw material comprises by weight: 25 parts of epoxy resin, 20 parts of polyester, 2 parts of coordination type titanate coupling agent, 12 parts of graphene oxide, 12 parts of zinc powder , 38 parts of siloxane oligomer, 6 parts of antimicrobial agent phthalimide, graphene oxide is a micro-sheet powder structure with a thickness of 4 μm and a diameter of 7 μm, zinc powder is a spherical structure with an average diameter of 2 μm .

[0058] Wherein, the preparation steps of siloxane oligomer are as follows:

[0059] (1) Zinc oxide is added to the aqueous solution containing propionic acid, and then silica sol is added to prepare a mixed aqueous solution;

[0060] (2) Mix methyltrimethoxysilane and phenylsilane in proportion, and then mix them with isopropanol to prepare a silanol solution, wherein the mass percentage of methyltrimethoxysilane and phenylsilane is 70:30, and methyltrimethoxysilane The mass percent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com