Water-based adhesive for dry-type composite of plastic films and preparation method thereof

A technology of dry compounding and plastic film, applied in adhesive types, ester copolymer adhesives, acid copolymer adhesives, etc., which can solve the problems of easy disintegration of polymer chains, low production efficiency, and high energy consumption , to achieve large particle size distribution, improve temperature resistance, and high adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

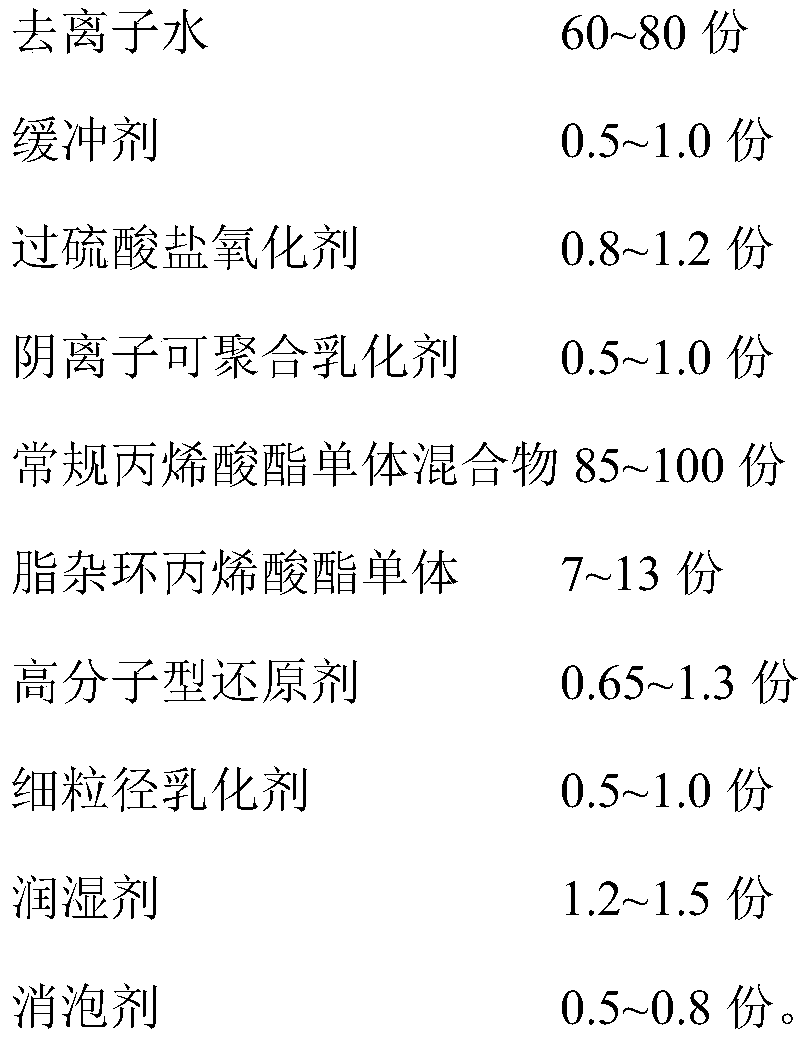

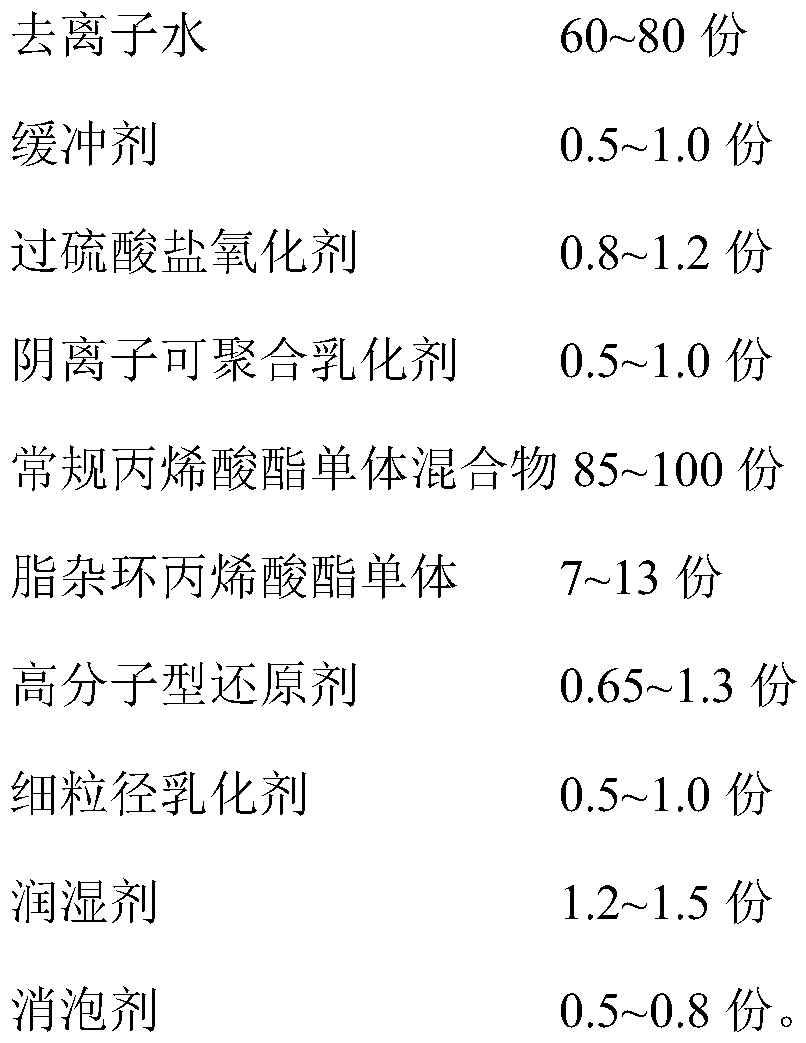

[0029] A water-based adhesive for dry compounding of plastic films in this embodiment is prepared by the following steps (the following components are all in parts by weight):

[0030] Step S1, add 20 parts of deionized water, 1.0 part of buffer sodium bicarbonate and 0.8 part of sodium persulfate oxidant into the reaction kettle, stir evenly to obtain the bottom liquid;

[0031] Step S2, take 25 parts of deionized water, 0.5 parts of polyether ammonium sulfate V-10S, 50 parts of conventional acrylate monomer mixture and 4 parts of tetrahydrofuryl methacrylate for pre-emulsification to obtain monomer pre-emulsion, and then add 0.4 Parts of high molecular weight reducing agent, stirred evenly to obtain monomer drop solution I;

[0032] Step S3, take 15 parts of deionized water, 0.5 parts of fine particle size emulsifier, 35 parts of conventional acrylate monomer mixture and 3 parts of tetrahydrofuryl methacrylate for pre-emulsification to obtain monomer pre-emulsion, and then a...

Embodiment 2

[0041] A water-based adhesive for dry compounding of plastic films in this embodiment is prepared by the following steps (the following components are all in parts by weight):

[0042] Step S1, add 30 parts of deionized water, 0.5 parts of buffer ammonium bicarbonate and 1.2 parts of ammonium persulfate oxidant into the reaction kettle, and stir evenly to obtain the bottom liquid;

[0043] Step S2, take 30 parts of deionized water, 1.0 parts of allyloxy fatty alcohol oxyethylene ether ammonium sulfate SR-10, 60 parts of conventional acrylate monomer mixture and 8 parts of tetrahydrofuryl acrylate for pre-emulsification to obtain monomer pre- Emulsion, then add 0.8 parts of high molecular weight reducing agent, stir evenly to obtain monomer drop solution I;

[0044] Step S3, take 20 parts of deionized water, 1.0 part of fine particle size emulsifier, 40 parts of conventional acrylate monomer mixture and 5 parts of tetrahydrofuryl acrylate for pre-emulsification to obtain a mono...

Embodiment 3

[0053] A water-based adhesive for dry compounding of plastic films in this embodiment is prepared by the following steps (the following components are all in parts by weight):

[0054] Step S1, add 27 parts of deionized water, 0.8 parts of buffer agent sodium dihydrogen phosphate and 1.0 part of potassium persulfate oxidizing agent into the reaction kettle, stir evenly to obtain the bottom liquid;

[0055] Step S2, taking 28 parts of deionized water, 0.9 parts of double bond-containing dialkyl sulfosuccinate M-30S, 57 parts of conventional acrylate monomer mixture and 6 parts of trimethylolpropane formal acrylate Pre-emulsify to obtain a monomer pre-emulsion, then add 0.6 parts of a polymer-type reducing agent, and stir evenly to obtain a monomer drop solution I;

[0056] Step S3, take 18 parts of deionized water, 0.7 parts of fine particle size emulsifier, 38 parts of conventional acrylate monomer mixture and 4 parts of trimethylolpropane formal acrylate for pre-emulsificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com