Preparation of magnetic porous graphene and rapid detection method of low-concentration triclosan in water by employing magnetic porous graphene

A technology of porous graphene and detection method, which can be used in measurement devices, instruments, scientific instruments, etc., can solve the problems of long liquid chromatography analysis time, high maintenance cost, low detection limit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a kind of preparation method of magnetic porous graphene, comprises the following steps:

[0038] (1) Graphene oxide and potassium hydroxide are mixed and activated to obtain porous graphene oxide;

[0039] (2) The porous graphene oxide, ferric chloride, sodium acetate and ethylene glycol are mixed for hydrothermal reaction to obtain magnetic porous graphene.

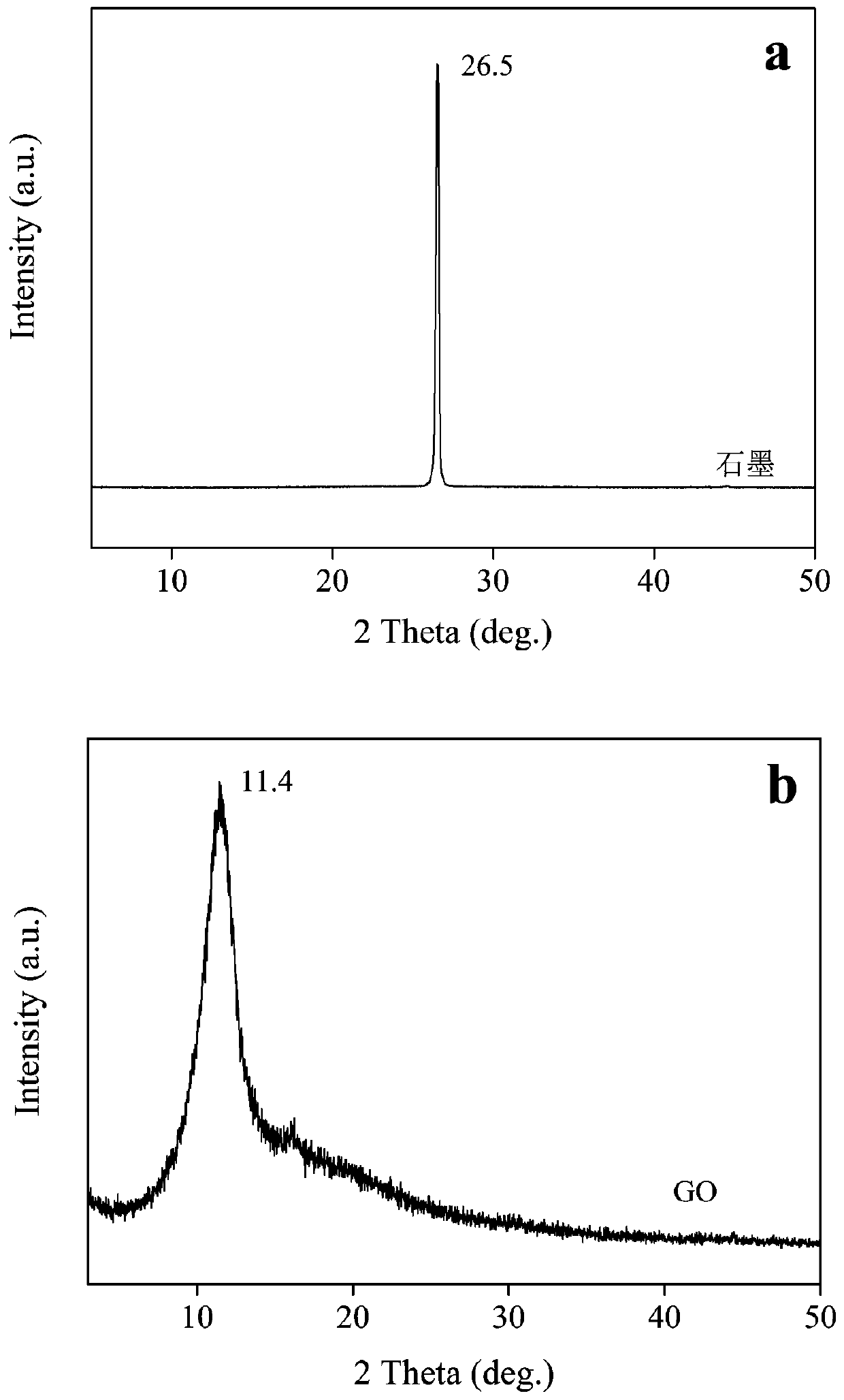

[0040] Graphene oxide and potassium hydroxide are mixed for activation treatment to obtain porous graphene oxide. In the present invention, the graphene oxide is preferably prepared by exfoliating flake graphite by a closed oxidation method, and the closed oxidation method preferably includes the following steps:

[0041] After mixing flake graphite, potassium permanganate and concentrated sulfuric acid, the low-temperature airtight oxidation reaction and high-temperature airtight oxidation reaction are carried out successively to obtain an oxidation reaction solution;

[0042] After dilu...

Embodiment 1

[0078] Graphene oxide (GO) is synthesized by using a closed oxidation method to prepare GO by chemical oxidation and exfoliation of flake graphite. The specific steps are as follows:

[0079] (1) Before the start of the experiment, put the used medicine and the inner tank of the reaction kettle into the refrigerator, and store them in cold storage at 4°C to ensure that the inner tank of the reaction kettle is dry.

[0080] (2) Weigh 1g flake graphite and 5g potassium permanganate respectively, mix them uniformly and pour them into a 100mL reactor liner, and then put the reactor liner into a stainless steel reactor jacket. Quickly add 50mL of concentrated sulfuric acid to the inner tank, quickly cover the inner tank cover and rotate the stainless steel reaction kettle cover tightly.

[0081] (3) Put the reaction kettle into the refrigerator, and store it in cold storage at 4°C for 14 hours. After the low-temperature reaction, put the reaction kettle into a 100°C oven to heat qu...

Embodiment 2

[0086] (1) Weigh 2g of GO prepared in Example 1 and 8g of potassium hydroxide, mix them into a tubular resistance furnace filled with nitrogen protection, and the resistance furnace is heated to 800°C at a rate of 5°C / min, and kept 1h. During this process, nitrogen gas has been fed in at a flow rate of 500 mL / min.

[0087] (2) After natural cooling, wash repeatedly 3 times with 0.1M hydrochloric acid solution and deionized water respectively, put into drying box and dry for 12h, take out, the powder at this moment is porous graphene oxide.

[0088] (3) Weigh 0.3 g of porous graphene oxide and dissolve it in 80 mL of ethylene glycol, and disperse it ultrasonically for 30 min. Weigh 0.3g of ferric chloride and 3.6g of sodium acetate and dissolve in 60mL of ethylene glycol, and ultrasonically disperse for 30min.

[0089] (4) After ultrasonication, the above two solutions were mixed and vigorously stirred for 1 hour, then poured into a 200 mL reactor, put the reactor into an ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com