Recovery and regeneration method of ternary positive electrode material of waste power lithium ion battery

A lithium-ion battery and positive electrode material technology, which is applied in the field of recycling and regeneration of waste power lithium-ion battery ternary positive electrode materials, can solve the problems of high recycling cost and long recycling process, achieve uniform particle size, shorten processing technology, The effect of excellent cycle performance and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

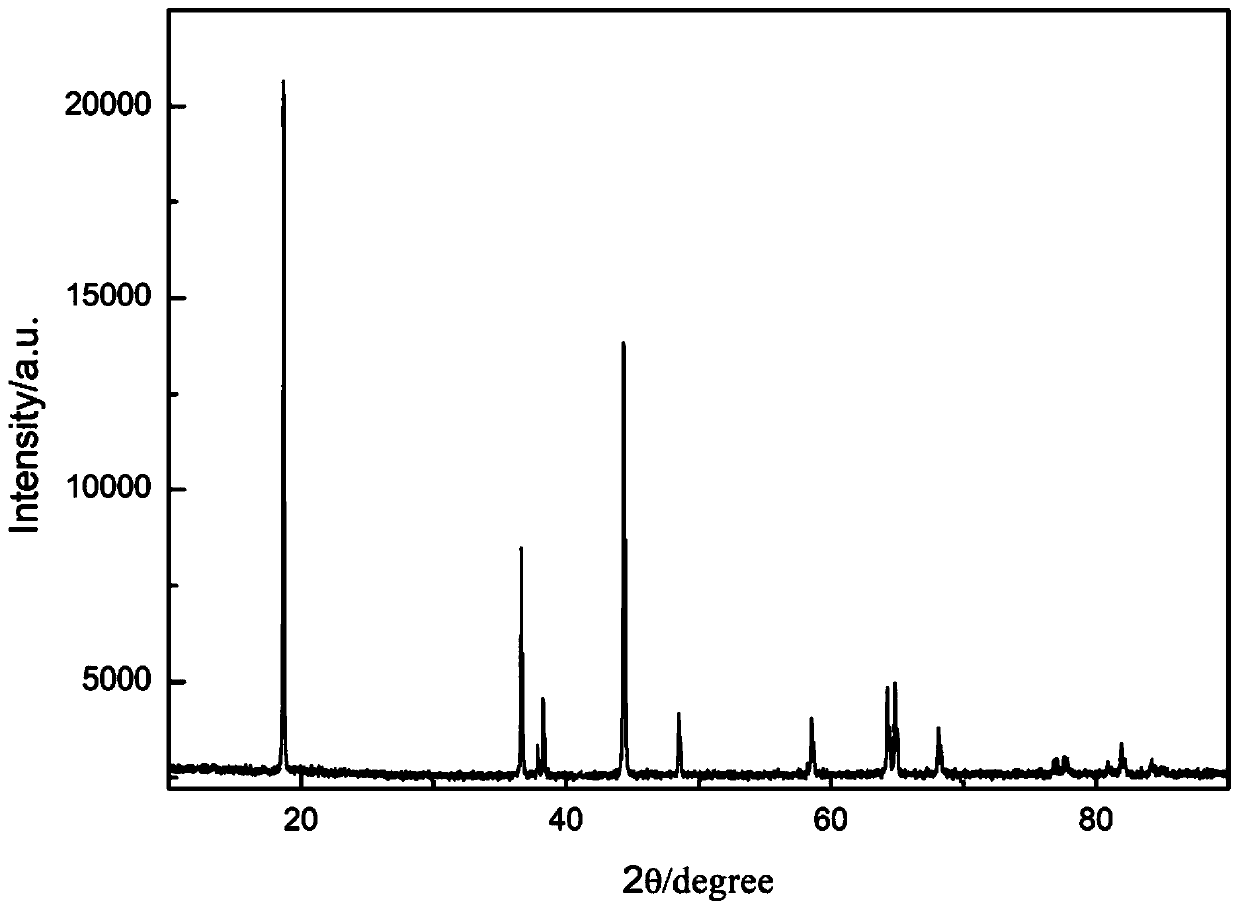

Image

Examples

Embodiment 1

[0033] After completely discharging the waste ternary power lithium-ion batteries of new energy vehicles, the recycling and regeneration of ternary positive electrode materials includes the following steps:

[0034] (1) Extraction of the positive pole piece of the waste power lithium-ion battery: After dismantling and shelling the completely discharged waste ternary power battery, separate the positive pole piece, negative pole piece, and diaphragm from the battery cell. After crushing and sieving the positive electrode sheet, a mixture A of ternary positive electrode material, binder, conductive agent and a small amount of aluminum powder is obtained.

[0035] (2) Purification of ternary positive electrode material waste: the mixture A obtained in step (1) is placed in a high-temperature incinerator, and incinerated under an oxidizing atmosphere. After natural cooling and screening, the ternary positive electrode material and Mixture B with very small amounts of aluminum. Th...

Embodiment 2

[0048] Embodiment 2 is the same as step (1), step (2) and step (3) in embodiment 1, the difference is only in step (4) and step (5):

[0049] (4) Dry gel preparation:

[0050] 4a) Weigh 1 ton of ternary material waste C and 10 kilograms of lithium borate for use;

[0051] 4b) according to the test result of step (3), according to the 15% of nickel, cobalt, manganese content in the ternary material scrap C that takes by weighing in the step (4a), take corresponding amount of nickel acetate, manganese acetate, cobalt acetate;

[0052] 4c) according to step (4a), step (4b) in the nickel-cobalt-manganese total molar number and the molar ratio of lithium are 1: 1.02 ratio, take the lithium acetate of corresponding amount;

[0053] 4d) according to the total moles of nickel acetate, manganese acetate, cobalt acetate, lithium acetate taken by weighing in step (4b), step (4c), take the citric acid of above-mentioned 1.5 times of total moles;

[0054] 4e) The nickel acetate, manganes...

Embodiment 3

[0059] Embodiment 3 is the same as step (1), step (2) and step (3) in embodiment 1, the difference is only in step (4) and step (5):

[0060] (4) Dry gel preparation:

[0061] 4a) Weigh 5 tons of ternary material waste C and 50 kilograms of aluminum trifluoride for use;

[0062] 4b) according to the test result of step (3), according to the 20% of nickel, cobalt, manganese content in the ternary material scrap C that weighs in the step (4a), take corresponding amount of nickel acetate, manganese acetate, cobalt acetate;

[0063] 4c) according to step (4a), step (4b) the total molar number of nickel cobalt manganese and the molar ratio of lithium are 1: 1.05 ratio, take the lithium acetate of corresponding amount;

[0064] 4d) according to the total moles of nickel acetate, manganese acetate, cobalt acetate, lithium acetate taken by weighing in step (4b), step (4c), take the citric acid of above-mentioned 1.8 times of total moles;

[0065] 4e) The nickel acetate, manganese ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com