Composite coating for titanium alloy investment casting, surface coating and preparation method and application thereof

A technology of investment precision casting and composite coating, which is applied in the direction of casting molding equipment, coating, metal processing equipment, etc., can solve the problem of poor stability and reliability of slurry coating, which affects the quality of shell in the coating process, zirconium acetate Does not have water resistance and other problems, and achieves the effects of small thickness, weakened hydration, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to describe the technical content, achieved objectives and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments.

[0040] Embodiment 1 of the present invention is: a surface coating for titanium alloy investment casting and its application in mold shell preparation, comprising the following steps:

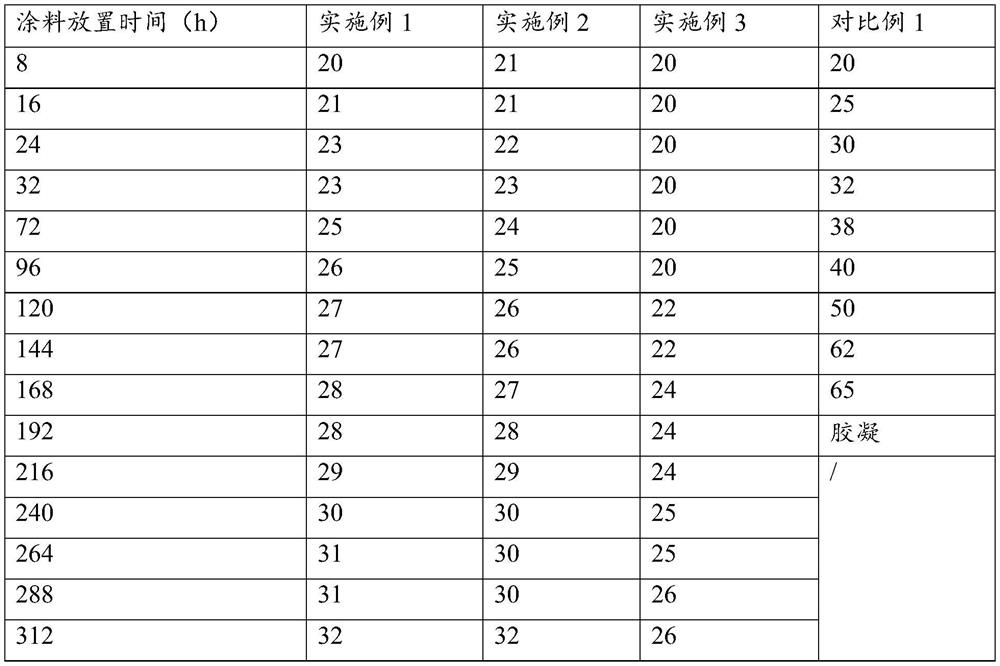

[0041] (1) Composite coating: Take 180 g of fused yttrium oxide powder, 25 g of zirconium acetate, 3 g of 3-hydroxybutyric acid, 13 g of acetic acid, 2 g of ethanol, and 3 g of propanol, mix them, and stir for 10 minutes to obtain a new composite coating;

[0042](2) Preparation of surface coating: Add 1.35g of JFC and 2.2g of secondary octanol to the prepared composite coating, and continue to stir for 30 minutes to obtain the top coating. The viscosity of the coating is measured at room temperature (25°C) to be 20s, and the preparation of the coating is complete. .

[0043] (3) Form shell preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com