Integrated composite electrode material, preparation method thereof and application thereof

A composite electrode and electrode sheet technology, applied in electrode manufacturing, battery electrode, electrolyte battery manufacturing, etc., can solve the problems of increased internal resistance of all-solid-state lithium-ion batteries, poor battery cycle performance, and difficulty in engineering. Achieve cost and labor savings, improve battery performance, and cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

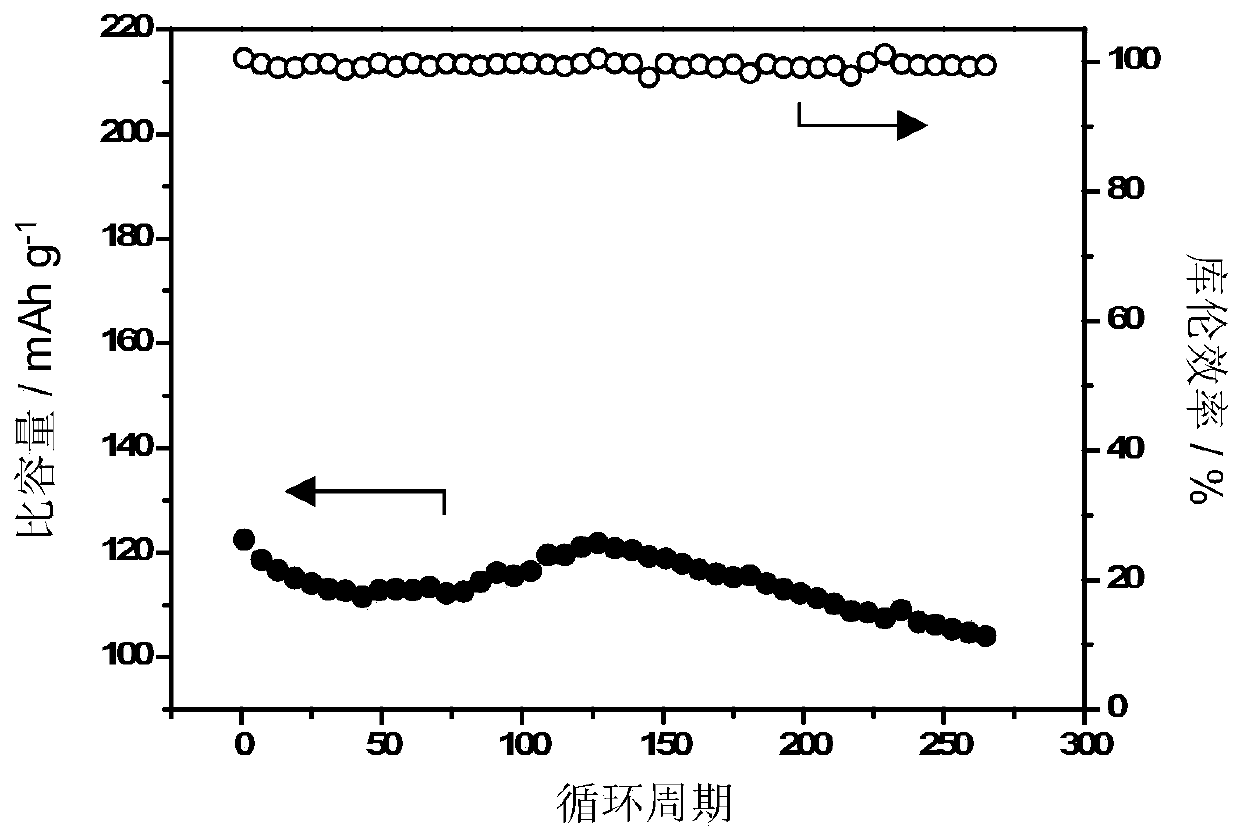

Embodiment 1

[0046] Step 1: Evenly disperse the active material-lithium cobaltate, the conductive agent-conductive carbon black and the binder-PVDF in NMP with a mass ratio of 8:1:1, coat the dispersion on aluminum foil and dry it Preparation of electrode pole pieces;

[0047] Step 2: The polymer electrolyte polyvinylidene fluoride-hexafluoropropylene, lithium salt LiClO 4 and inorganic solid electrolyte lithium lanthanum titanium oxide particles are dissolved in acetonitrile to prepare spinning solution, wherein the concentration of polymer electrolyte is 10wt%, the mass ratio of lithium salt and polymer electrolyte is 0.05, the mass ratio of inorganic solid electrolyte and polymer electrolyte is 0.05;

[0048] Step 3: Use the electrode pole piece obtained in Step 1 as the receiving end of electrospinning, the electrospinning voltage is 15kV, the receiving distance is 20cm, the temperature is 20°C, the humidity is 40%RH, the diameter of the spinning fiber is controlled to be 50nm, and th...

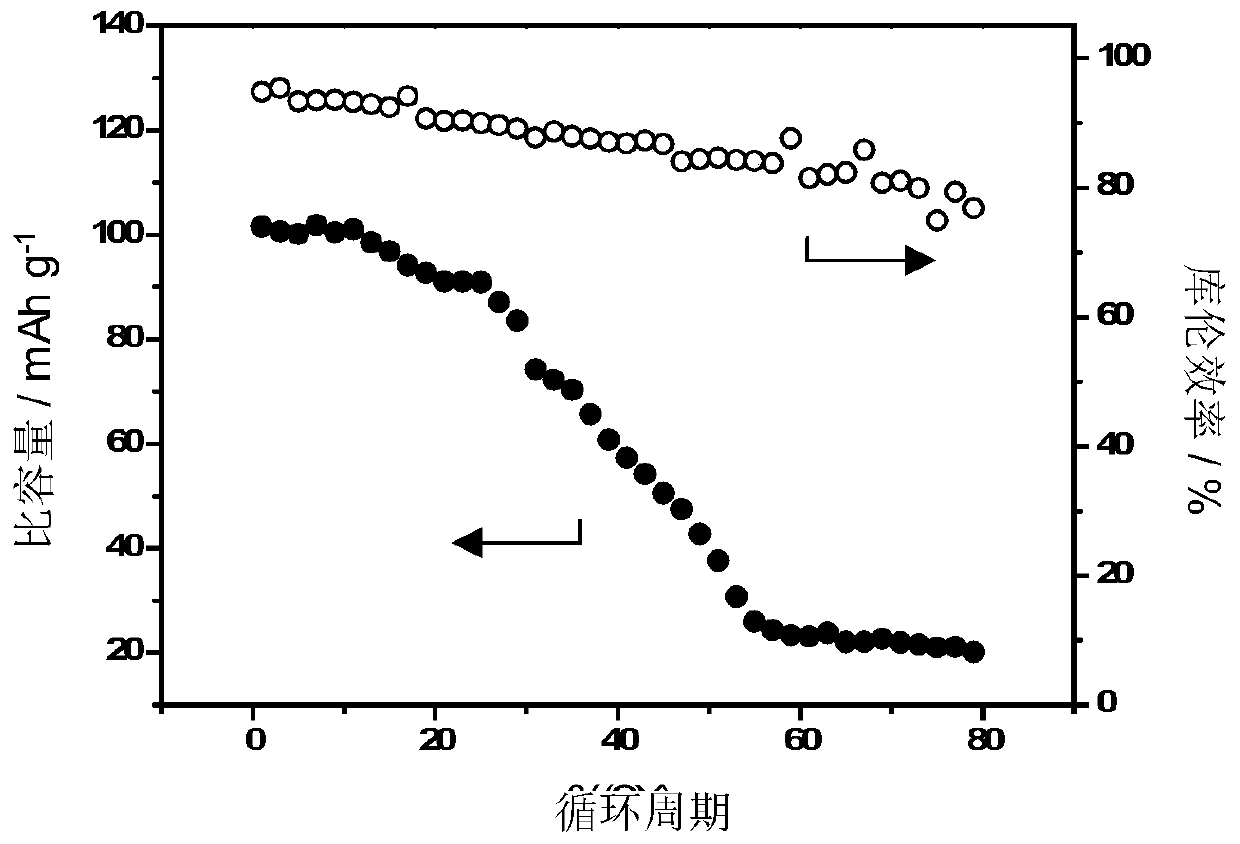

Embodiment 2

[0052] Step 1: Evenly disperse the active material-nickel cobalt lithium manganate, conductive agent-Ketjen black and binder-PVDF in NMP with a mass ratio of 95:2:3, and coat the dispersion on aluminum foil and drying to prepare electrode sheets;

[0053] Step 2: The polymer electrolyte polyacrylonitrile, lithium salt LiPF 6 and inert filler aluminum oxide particles are dissolved in acetonitrile to prepare spinning solution, wherein the concentration of polymer electrolyte is 8wt%, the mass ratio of lithium salt and polymer electrolyte is 0.1, and the mass ratio of inorganic solid electrolyte and polymer electrolyte is 0.1;

[0054] Step 3: Use the electrode pole piece obtained in Step 1 as the receiving end of electrospinning, the electrospinning voltage is 18kV, the receiving distance is 15cm, the temperature is 40°C, the humidity is 20%RH, the diameter of the spinning fiber is controlled to be 30nm, and the fiber is For conjugate orientation, the spinning solution is spun...

Embodiment 3

[0057] Step 1: Evenly disperse the active material-silicon carbon material, conductive agent-carbon nanotubes and binder-PTFE in water with a mass ratio of 94:3:3, coat the dispersion on copper foil and dry it Preparation of electrode pole pieces;

[0058] Step 2: Dissolving the polymer electrolyte polyethylene oxide, lithium salt LiTFSI and inorganic solid electrolyte lithium titanium aluminum phosphate particles in DMF to prepare a spinning solution, wherein the concentration of the polymer electrolyte is 12wt%, the quality of the lithium salt and the polymer electrolyte The ratio is 0.2, and the mass ratio of the inorganic solid electrolyte and the polymer electrolyte is 0.2;

[0059] Step 3: Use the electrode pole piece obtained in Step 1 as the receiving end of electrospinning, the electrospinning voltage is 20kV, the receiving distance is 10cm, the temperature is 30°C, the humidity is 30%RH, the diameter of the spinning fiber is controlled to be 80nm, and the drum is par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com