Structure of multi-sphere carbon-coated manganese dioxide composite material and preparation method thereof

A manganese dioxide and composite material technology, applied in structural parts, secondary batteries, electrochemical generators, etc., can solve the problems of difficult batch preparation, industrial application obstacles, and high cost of carbon fiber cloth, and achieve improved electrical conductivity and Electrochemical stability, excellent electrochemical performance, and low requirements for equipment parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Electrolytic MnO 2 The material is mixed with graphite, carbon nanotubes, sucrose, and polyacrylic acid in a mass ratio of 80:5:10:2.5:2.5 (total solid content is 100g), and dispersed in 300ml deionized water under ball milling conditions to form a dispersion solution.

[0028] Step 2: Add 2 grams of benzoic acid to the above dispersant, and continue stirring for 12 hours to form a uniform slurry.

[0029] Step 3: Spray granulate the slurry obtained in Step 2, set the spray pressure to 0.4 MPa, and the material inlet temperature to 120°C. The spray-granulated material was then collected.

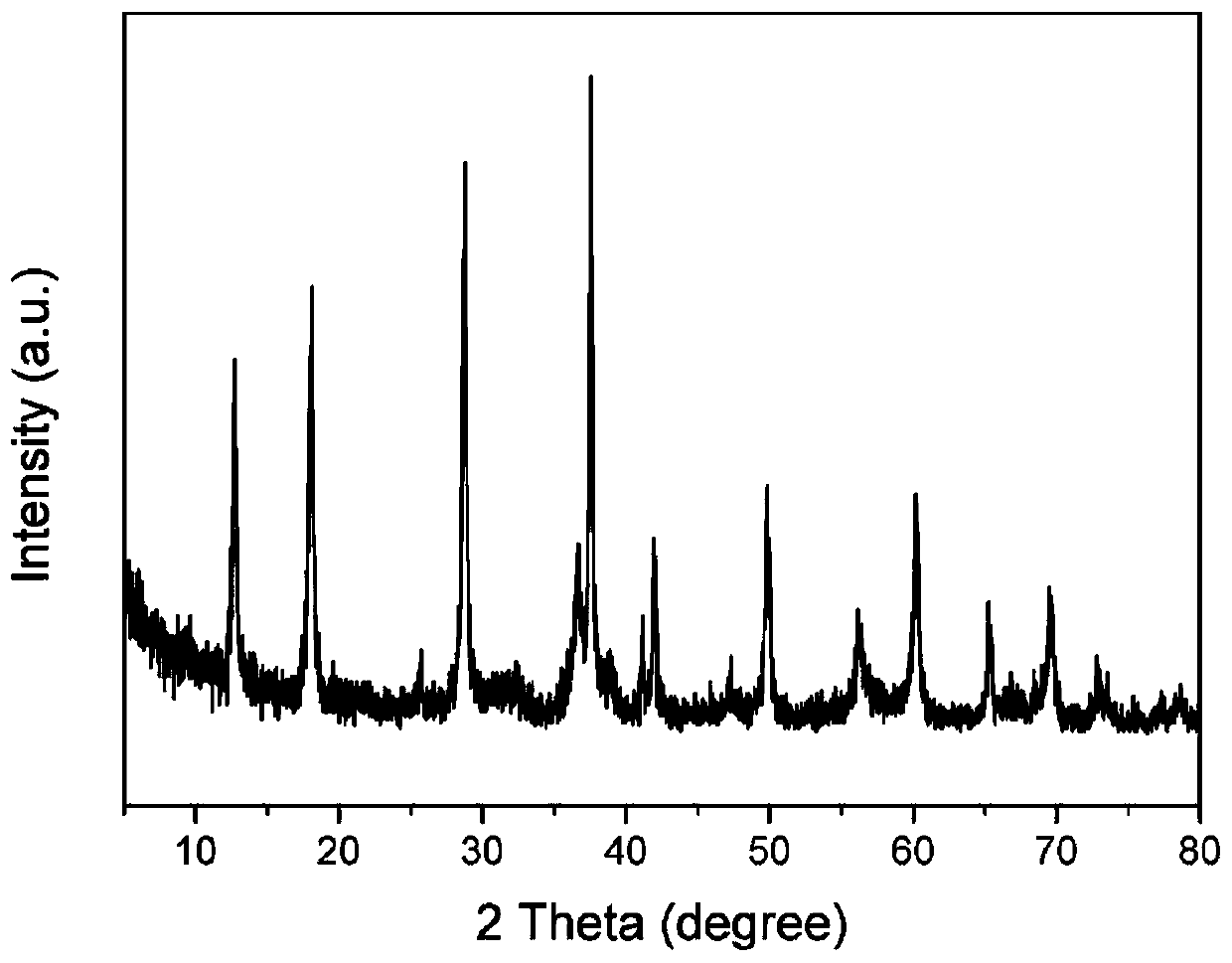

[0030] Step 4: Put the material obtained in Step 3 in a tube furnace, and heat-treat it in a nitrogen atmosphere at 800° C. for 24 hours to obtain a multi-sphere stacked carbon-coated manganese dioxide composite material with excellent crystallization properties. figure 1 XRD pattern of the obtained carbon-coated manganese dioxide composite material. It can be seen from the ...

Embodiment 2

[0033] Step 1: Add α-MnO 2 The material is mixed with acetylene black, glucose, carbon fiber, and sodium lauryl sulfate according to the mass ratio of 75:10:10:2.5:2.5 (total solid content is 100g), and dispersed in 300ml deionized water under ball milling conditions to form a slurry material.

[0034] Step 2: Add 4 grams of PMMA to the above dispersant, and continue stirring for 6 hours to form a uniform slurry.

[0035] Step 3: Spray granulate the slurry obtained in Step 2, set the spray pressure to 0.3 MPa, and the material inlet temperature to 110°C. The spray-granulated material was then collected.

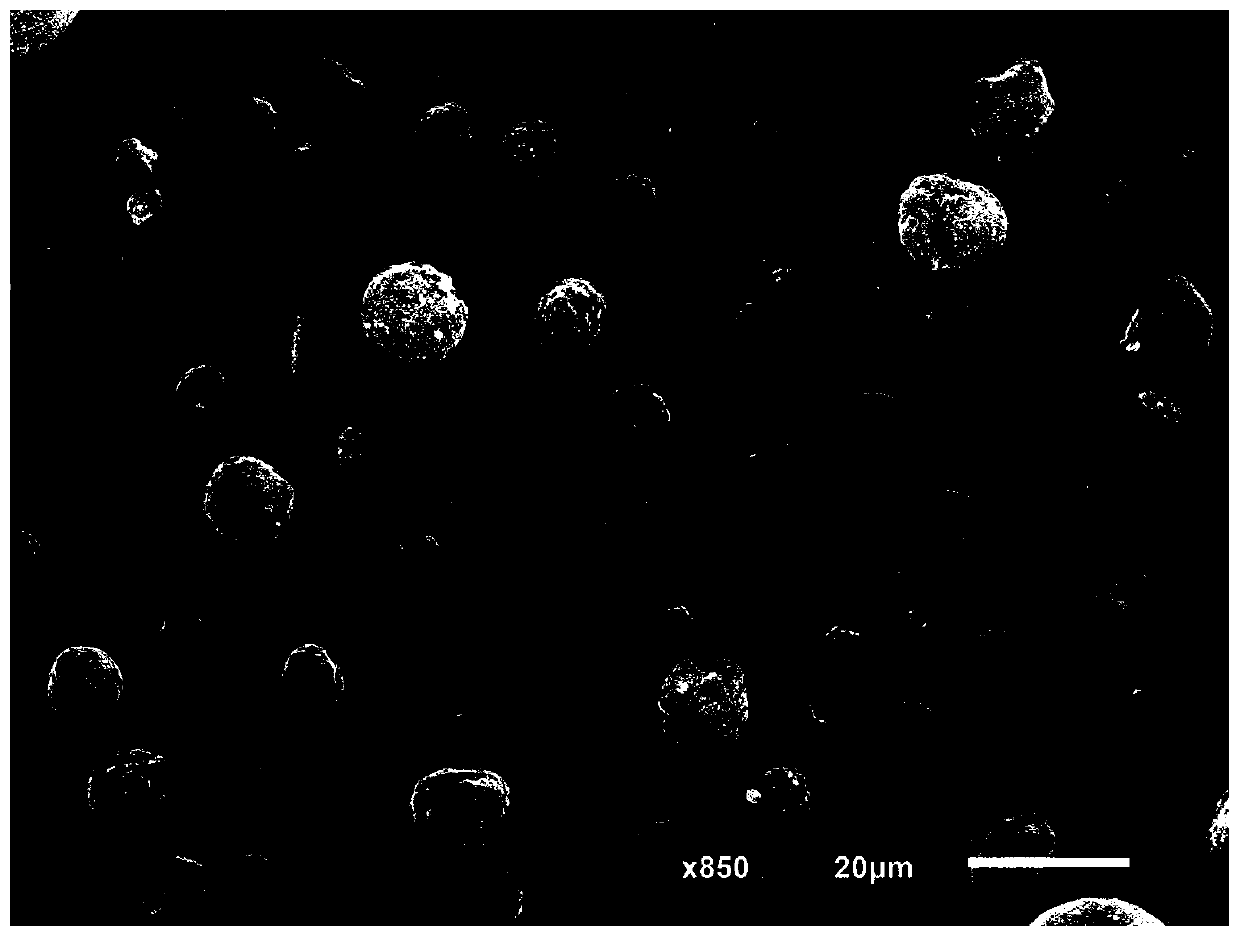

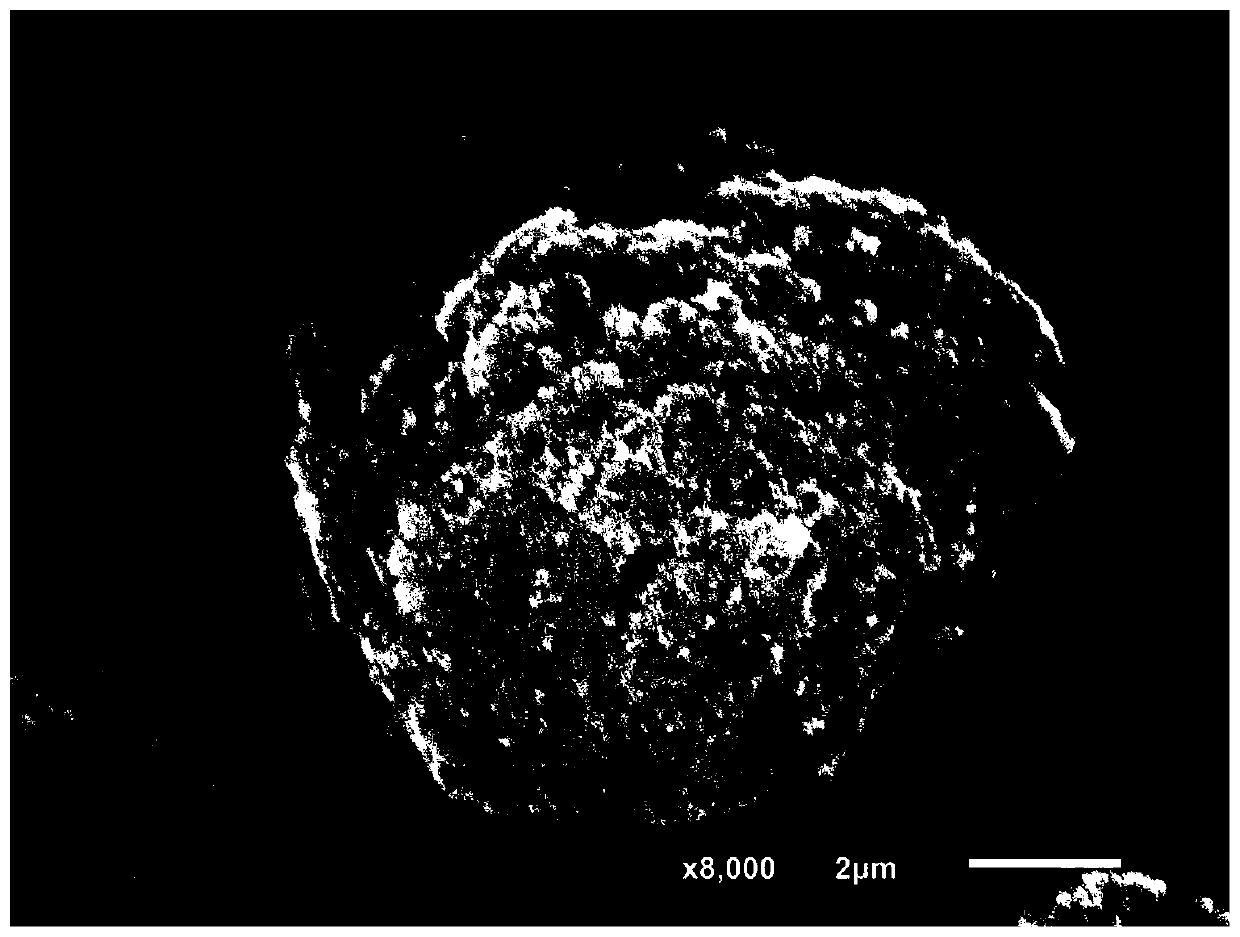

[0036] Step 4: Put the material obtained in step 3 in a tube furnace and heat-treat it under an argon atmosphere at 600°C for 12 hours to obtain a multi-sphere stacked carbon-coated manganese dioxide composite material with excellent crystallization properties. Its scanning electron microscope Figure such as Figure 7 shown.

[0037] Apply this material to the positive e...

Embodiment 3

[0039] Step 1: Add β-MnO 2 The material is mixed with acetylene black, citric acid, carbon nanotubes, and polyacrylic acid in a mass ratio of 70:15:10:2.5:2.5 (total solid content is 100g), and dispersed in 300ml deionized water under ball milling conditions to form a slurry .

[0040] Step 2: Add 5 grams of benzoic acid to the above dispersant, and continue stirring for 6 hours to form a uniform slurry.

[0041] Step 3: Spray granulate the slurry obtained in Step 2, set the spray pressure to 0.25 MPa, and the material inlet temperature to 105°C. The spray-granulated material was then collected.

[0042] Step 4: Put the material obtained in Step 3 in a tube furnace, and heat-treat it under an argon atmosphere at 750° C. for 24 hours to obtain a carbon-coated manganese dioxide composite material with excellent crystallization properties.

[0043] Apply this material to the positive electrode material of neutral zinc-manganese battery, and its specific capacity can reach 235m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com