Environment-friendly highlight waterborne gloss oil and preparation method thereof

A water-based varnish, environmental protection technology, applied in paints containing biocide, anti-fouling/underwater coatings, coatings, etc. Reduce the light effect and other problems, and achieve the effect of excellent substrate adhesion, good adhesion, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

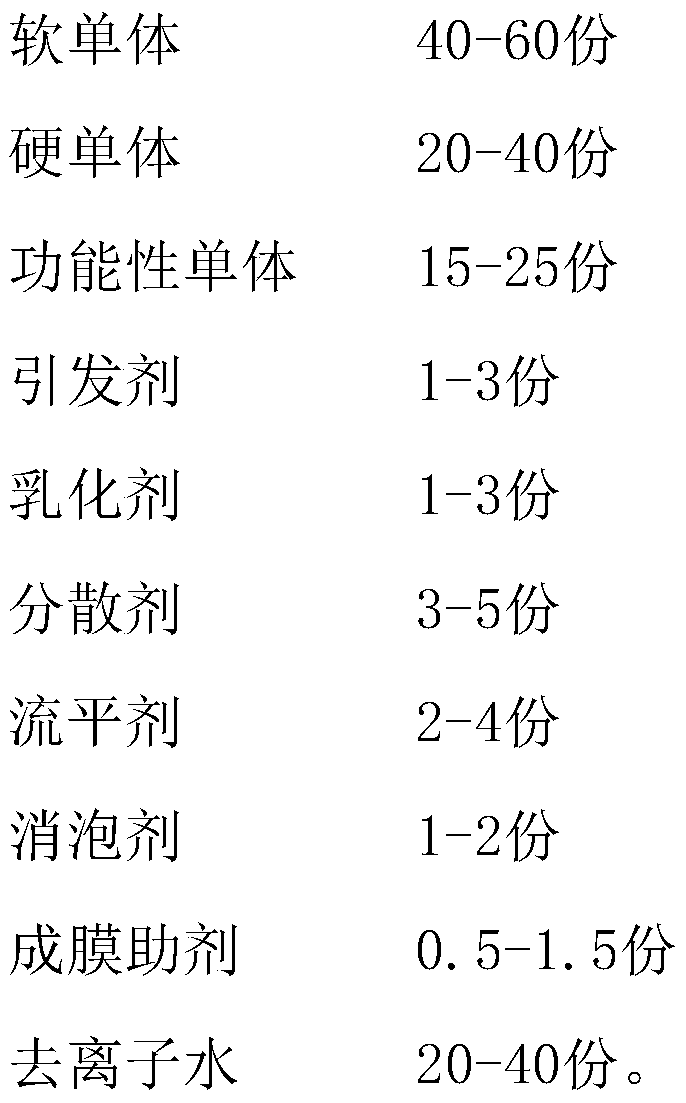

[0025] An environment-friendly high-gloss water-based varnish, comprising the following raw materials in parts by weight:

[0026]

[0027]

[0028] The soft monomer is a mixture composed of butyl acrylate, isooctyl acrylate and lauryl methacrylate in a weight ratio of 2:1.5:1.

[0029] The hard monomer is a mixture of styrene, methyl acrylate and n-butyl methacrylate in a weight ratio of 1:1.4:1.

[0030] The functional monomer is a mixture composed of acrylonitrile, N-methylolacrylamide, hydroxypropyl methacrylate and glycidyl methacrylate in a weight ratio of 1.5:0.5:0.8:1.

[0031] The initiator is potassium persulfate, sodium persulfate or ammonium persulfate.

[0032] Described emulsifier is sodium lauryl sulfate or sodium dodecylbenzene sulfonate; Described dispersant is calcium stearate, magnesium stearate, zinc stearate or barium stearate; Described leveling The agent is polydimethylsiloxane.

[0033] The defoamer is emulsified silicone oil; the film-forming ...

Embodiment 2

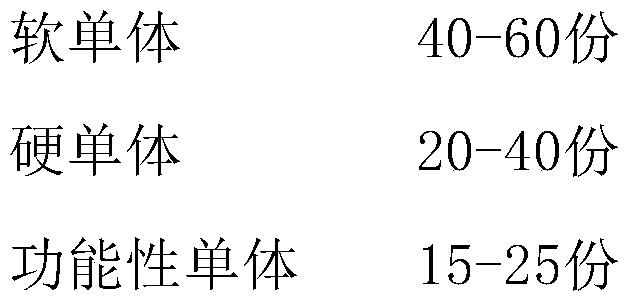

[0036] An environment-friendly high-gloss water-based varnish, comprising the following raw materials in parts by weight:

[0037]

[0038] The soft monomer is a mixture of butyl acrylate, isooctyl acrylate and dodecyl methacrylate in a weight ratio of 2.5:1.8:1.

[0039] The hard monomer is a mixture of styrene, methyl acrylate and n-butyl methacrylate in a weight ratio of 1.5:1.6:1.

[0040] The functional monomer is a mixture composed of acrylonitrile, N-methylolacrylamide, hydroxypropyl methacrylate and glycidyl methacrylate in a weight ratio of 1.8:0.8:0.9:1.

[0041] The initiator is azobisisobutyronitrile or azobisisoheptanonitrile.

[0042] The emulsifier is nonylphenol polyoxyethylene ether, octylphenol polyoxyethylene ether or alkylphenol polyoxyethylene ether; the dispersant is butyl stearate; the leveling agent is polymethylbenzene base siloxane.

[0043] The defoaming agent is a high-carbon alcohol fatty acid ester compound; the film-forming aid is dodecyl a...

Embodiment 3

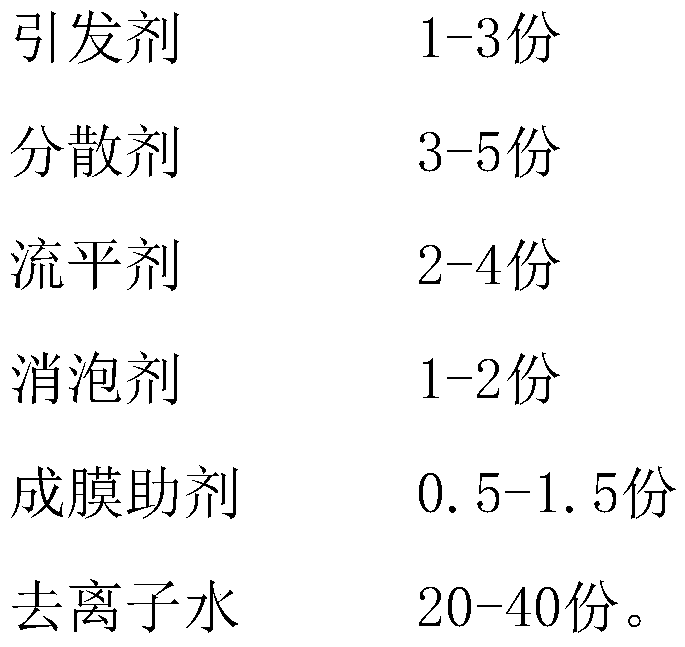

[0046] An environment-friendly high-gloss water-based varnish, comprising the following raw materials in parts by weight:

[0047]

[0048] The soft monomer is a mixture of butyl acrylate, isooctyl acrylate and dodecyl methacrylate in a weight ratio of 3:2:1.

[0049] The hard monomer is a mixture composed of styrene, methyl acrylate and n-butyl methacrylate in a weight ratio of 2:1.8:1.

[0050] The functional monomer is a mixture composed of acrylonitrile, N-methylolacrylamide, hydroxypropyl methacrylate and glycidyl methacrylate in a weight ratio of 2:1:1:1.

[0051] The initiator is benzoyl peroxide, lauroyl peroxide, cumene hydroperoxide, tert-butyl hydroperoxide, di-tert-butyl peroxide or dicumyl peroxide.

[0052] The emulsifier is styrene-ethylphenol polyoxypropylene polyoxyethylene ether, benzylphenol polyoxyethylene ether or styrene-ethylphenol polyoxyethylene ether; the dispersant is ethylene bis stearamide; the leveling The agent is polyether polyester modifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com