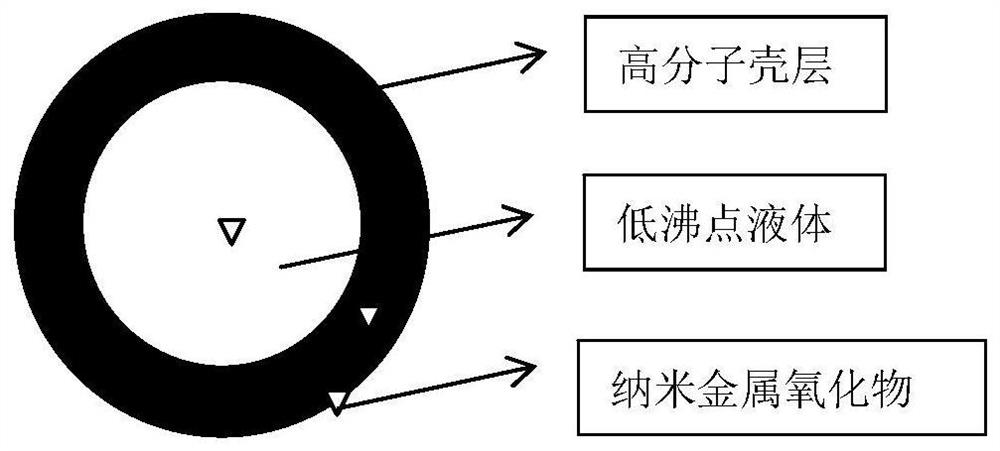

A kind of preparation method of nanometer metal oxide modified heat-expandable microsphere

A technology of thermally expanding microspheres and nano-metals, which is applied in the preparation of microspheres, microcapsule preparations, etc., to achieve the effects of moderate viscoelasticity, simple operation and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of the nano-metal oxide modified heat-expandable microspheres consists of the following steps:

[0044] (1) 100 parts by weight of saturated brine (magnesium sulfate / sodium chloride=5 / 5), 0.5 parts by weight of emulsifier NP-10, 0.03 parts by weight of wetting agent sodium diisobutylnaphthalene sulfonate, 20 parts by weight Emulsifying and dispersing agent nano-silica, 0.01 parts by weight of pH regulator 20wt.% hydrochloric acid, 5 parts by weight of functional water-soluble monomer methacrylamide, 0.001 parts by weight of nano-metal oxide and nano-iron oxide are added to the pressure reactor, and nitrogen is exhausted Oxygen, start stirring, control the speed of 1000r / min, raise the temperature to 35°C, stir for 30min, and form the water phase;

[0045] (2) 100 parts by weight of acrylic mixed monomers (1% of methacrylic acid-2-hydroxyethyl ester, 35% of acrylonitrile, 16% of acrylic acid, 48% of methacrylic acid), 20 parts by weight of low boil...

Embodiment 2

[0048] The preparation method of the nano-metal oxide modified heat-expandable microspheres consists of the following steps:

[0049] (1) 100 parts by weight of saturated sodium chloride brine, 2.5 parts by weight of emulsifier OP-10, 0.05 parts by weight of wetting agent sodium methylene bis-naphthalene sulfonate, 5 parts by weight of emulsifying dispersant hydrotalcite, 0.005 parts by weight of Add pH regulator citric acid, 2 parts by weight of functional water-soluble monomer dimethylaminoethyl acrylate, and 0.2 parts by weight of nano-metal oxide nano-alumina to the pressure reactor, nitrogen exhaust oxygen, start stirring, control the speed of 1000r / min, Raise the temperature to 38°C and stir for 30 minutes to form the water phase;

[0050] (2) Mix 100 parts by weight of acrylic acid mixed monomer (glycidyl methacrylate 2%, acrylonitrile 30%, methacrylic acid 68%), 40 parts by weight of low boiling point liquid (18 parts of isooctane, isopentane 22 parts), 2 parts by wei...

Embodiment 3

[0053] The preparation method of the nano-metal oxide modified heat-expandable microspheres consists of the following steps:

[0054] (1) 100 parts by weight of saturated magnesium sulfate brine, 2.0 parts by weight of emulsifier Tween-80, 0.05 parts by weight of wetting agent lauryl alcohol polyoxyethylene ether, 15 parts by weight of emulsifying dispersant nano silicon dioxide, Add 2.0 parts by weight of pH regulator salicylic acid, 3 parts by weight of functional water-soluble monomer methacrylamide, and 0.05 parts by weight of nano-metal oxide nano-zinc oxide into the pressure reactor, nitrogen exhaust oxygen, start stirring, and control the speed of 800r / min, heat up to 40°C, stir for 30 min, and form the water phase;

[0055] (2) Mix 100 parts by weight of acrylic acid mixed monomer (1% dimethylaminoethyl acrylate, 30% acrylonitrile, 69% methacrylic acid), 30 parts by weight of low boiling point liquid (5 parts of isobutane, 5 parts of isooctane 20 parts, 5 parts of pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com