A kind of sol-gel polishing pill added with water-resistant coating soluble filler and preparation method thereof

A coating, water-soluble resin technology, applied in the field of sol-gel polishing pellets and their preparation, can solve the problems of difficult to guarantee the surface shape, decreased strength, low rubber hardness, etc., to enhance adsorption potential energy, reduce internal defects, absorb powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

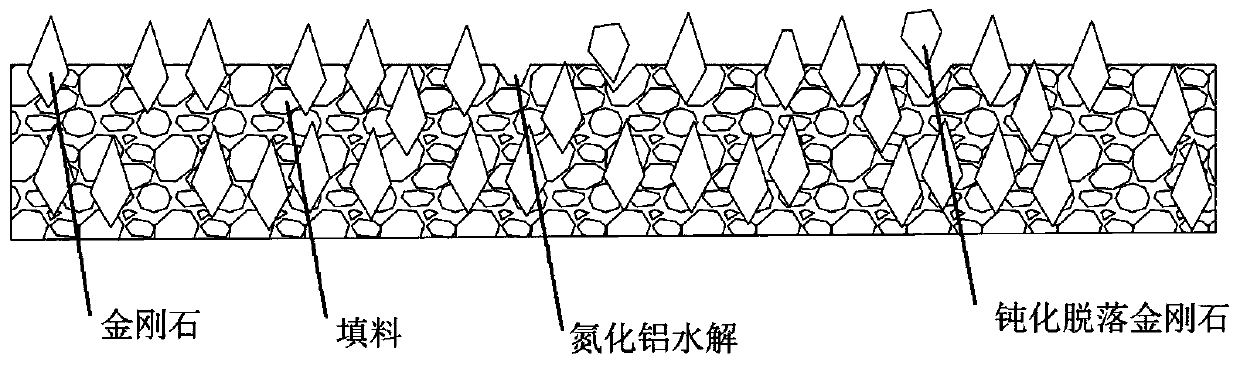

[0032] Step 1: Prepare aluminum nitride powder with a water-resistant film on the surface

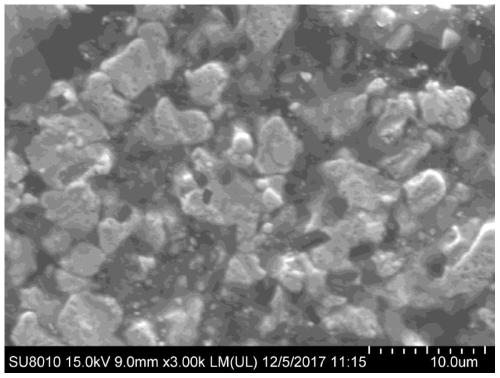

[0033] By weight, mix 100g of aluminum nitride powder with a particle size of 1 micron and 1kg of absolute ethanol, stir evenly, and heat up to 40°C in a water bath to obtain an ethanol dispersion of aluminum nitride; at the same time, dilute 600g of absolute ethanol Add 80g of tetraethyl orthosilicate (TEOS), and 100g of ammonia water diluted with 600g of absolute ethanol and 100g of water dropwise into the aluminum nitride ethanol dispersion at a rate of 2 drops / second. After reacting for 6 hours, stop the reaction, vacuum filter, wash the product 3 times with absolute ethanol, then place the obtained product at room temperature for 12 hours, and then place it at 300°C for calcination for 2 hours, after cooling , through a 200-mesh sieve, the aluminum nitride powder coated with silicon dioxide is obtained; , because the silicon dioxide has water resistance, the aluminum nitride powder...

Embodiment 2

[0037] Germanium flat lens polishing process:

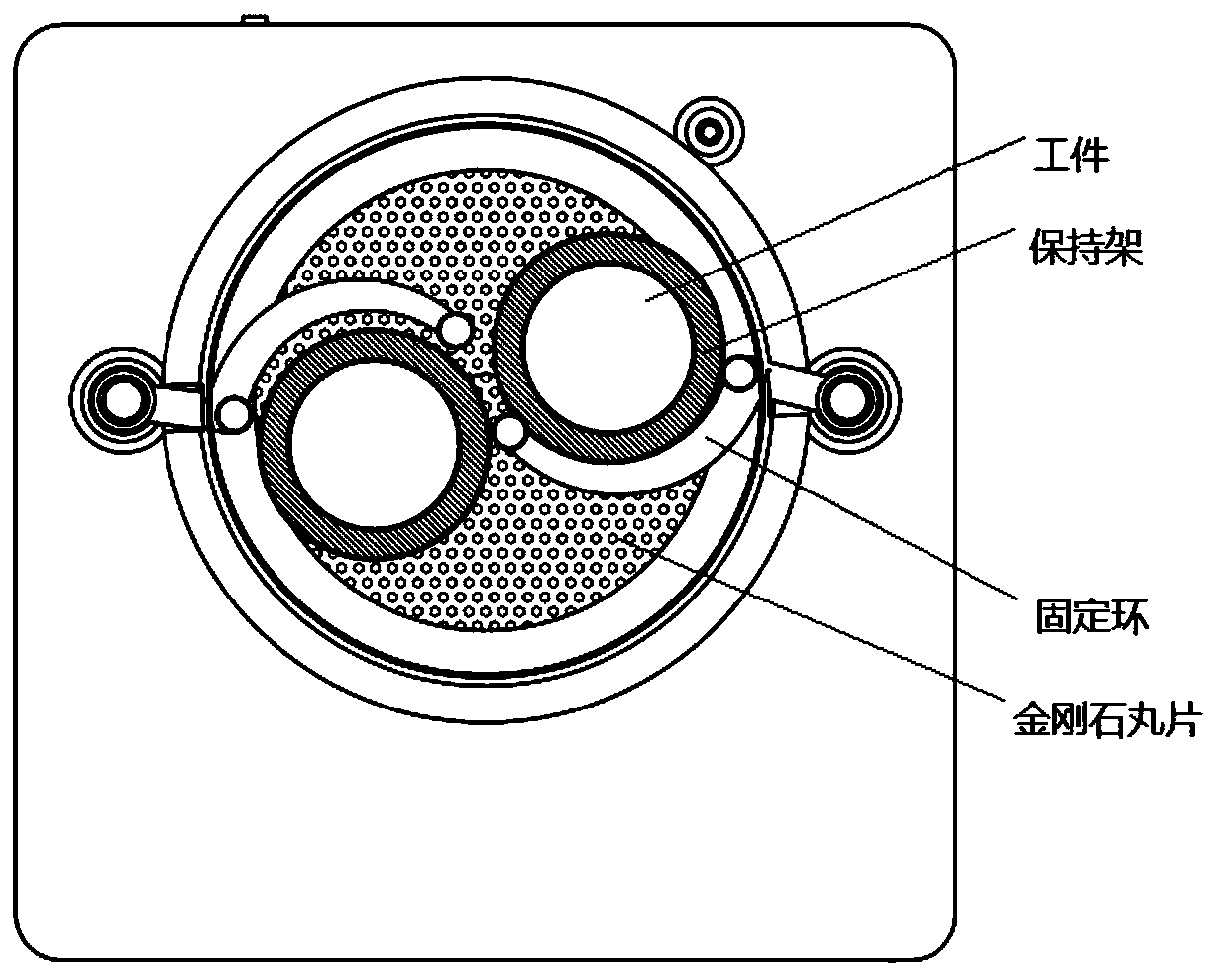

[0038] The schematic diagram of the polishing method is as follows: image 3 As shown, a germanium plane lens with a diameter of 100 mm is pasted on the ceramic substrate with wax, and the plane lens is first ground with a 10 micron diamond polishing liquid and a silicon carbide grinding disc until the surface roughness reaches 25 nm. The obtained pellets are pasted on the cast iron plate, the diameter of the cast iron plate is 200 mm, the surface of the pellets is smoothed on a surface grinder, and the vertical error is less than 2 microns, the cast iron plate is placed on the base plate of the plane polishing machine, and the ceramic base plate is clamped with a clamp. The speed of the polishing disc is 100rpm, the clamp is pneumatically pressurized, and the pressure is 5Mpa. During the polishing process, an acidic polishing solution is added to the surface of the pellets. The pH value is 5, and the flow rate is 100ml / min. 5, ...

Embodiment 3

[0040] Operation is basically the same as in Example 1, except that in step 2, the amount of aluminum nitride powder coated with silicon dioxide is increased to 150g, and after sintering, the strength of the pellet substrate can still be maintained under dry conditions, and the stretching The strength reached 25Mpa, the flexural strength was 60Mpa, and the elongation at break was 145%. After soaking in water for 1 hour, the tensile strength was 23Mpa, and the flexural strength was 55Mpa. After drying, weigh the weight and the weight dropped by 0.5g ; After 2 hours, the tensile strength was 22Mpa, the flexural strength was 53Mpa, and the strength drop was not obvious. After drying, the weight was weighed, and the weight dropped by 0.4g.

[0041] After rubbing the surface of the pills, weigh the original weight of the pills, soak in water for 1 hour, the overall tensile strength of the pills is 23Mpa, and the flexural strength is 55Mpa. After drying, weigh the weight, and the wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com