Electroreduction preparation method of vandetanib and analog intermediates

A technology of electrodes and derivatives, which is applied in the direction of electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of environmental pollution, large environmental pollution, and excessive heavy metals affecting the purity of intermediates and anticancer drug products, so as to reduce production costs, The effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

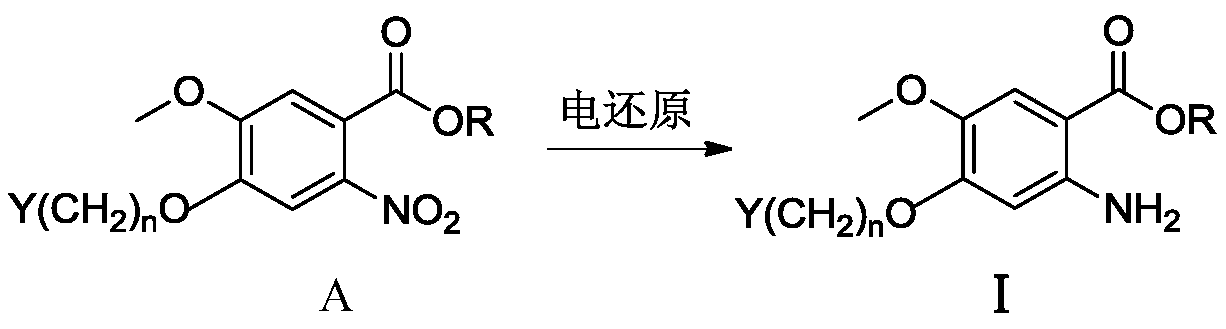

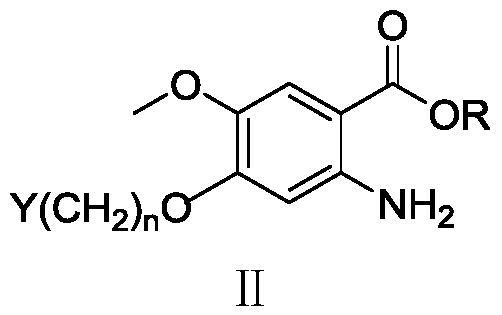

[0063] Electroreduction Preparation of Methyl 2-Amino-5-methoxy-4-(3-chloropropoxy)benzoate

[0064]

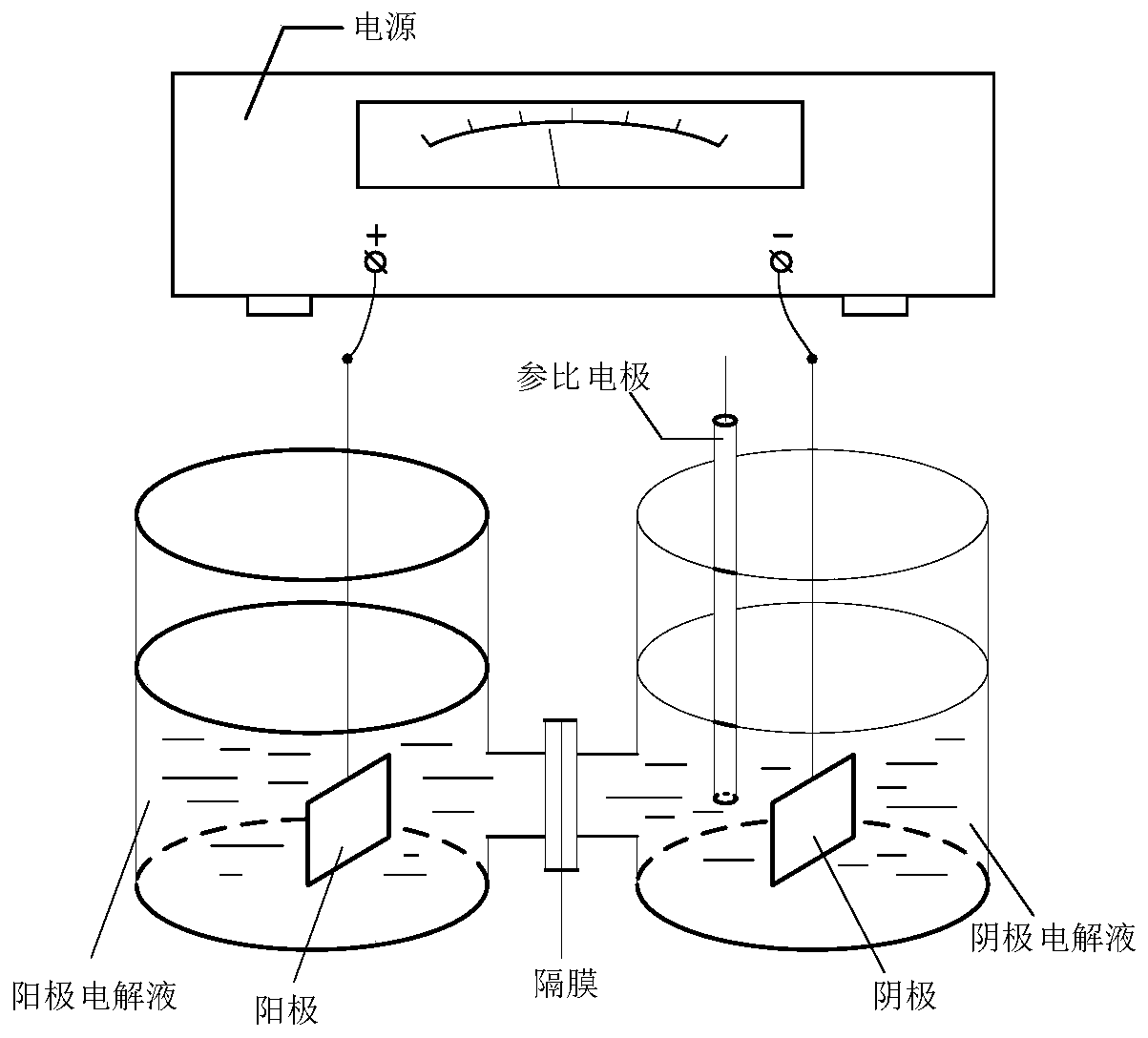

[0065] Install the diaphragm electrolyzer ( figure 1 ), separated by HF-101 strong acid cation exchange membrane. Add 0.61g of 5-methoxy-4-(3-chloropropoxy)-2-nitrobenzoic acid methyl ester to the cathode (Cu) electrolyzer of the diaphragm electrolyzer, add 30ml of acetonitrile, and then add 1mol / L 30ml of aqueous hydrochloric acid solution; add 60ml of 0.25mol / L sulfuric acid aqueous solution to the anode (DSA) electrolyzer, and stir in a 40°C constant temperature water bath; power reduction: the voltage of the reference electrode relative to the working electrode is 2.0V, and the power supply voltage is 25V , current 0.65A, cathode electrode (brass 2cm × 2cm), anode electrode (platinum mesh 1cm × 1cm) electrolytic reduction 3.0h. After the reaction was completed, neutralize with potassium carbonate, extract with dichloromethane, combine the organic layers, dry over anh...

Embodiment 2

[0066] Embodiment 2 (control experiment)

[0067] Preparation of methyl 2-amino-5-methoxy-4-(3-chloropropoxy)benzoate

[0068]

[0069] Prepared according to [Euro J Med Chem 2017, 138:669~688], using iron powder to reduce 5-methoxy-4-(3-chloropropoxy)-2-nitrobenzoic acid in acetic acid at 80°C Methyl ester to obtain methyl 2-amino-5-methoxy-4-(3-chloropropoxy)benzoate with a yield of 82% and a melting point of 97-99°C.

Embodiment 3

[0071] Electroreduction Preparation of Methyl 2-Amino-5-methoxy-4-(3-morpholinopropoxy)benzoate

[0072]

[0073] Install the diaphragm electrolyzer ( figure 1 ), separated by HF-101 strong acid cation exchange membrane. Add a magnetic stirrer bar, 0.36g 5-methoxy-4-(3-morpholinopropoxy)-2-nitrobenzoic acid methyl ester and 60mL0.5mol / L hydrochloric acid solution in the cathode (Cu) electrolyzer, Stir to dissolve, add 60mL 0.25mol / L sulfuric acid solution in the anode (DSA) electrolytic cell; the cathode uses a saturated calomel electrode as a reference electrode, and conducts constant current electrolysis with a current density of 200mA / cm 2 , the voltage between the cathode and the reference is between 1.2 and 1.6V; stir at 40°C for 4.0h, after the reaction is complete, the catholyte is adjusted to weak alkaline with 10% NaOH solution, extracted twice with dichloromethane, dried over anhydrous sodium sulfate , suction filtration, solvent precipitation, recrystallization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com