Nitrogen-rich hierarchical pore biomass charcoal and application thereof

A biomass charcoal, multi-level pore technology, applied in the direction of carbon compounds, other chemical processes, inorganic chemistry, etc., can solve the problems of underdeveloped pore structure and low nitrogen content, and achieve high nitrogen content, large specific surface area, Effects of high nitrogen incorporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Specifically, the nitrogen-rich hierarchical porous biochar is prepared by the following method:

[0031] A, placing biomass and carbon nitride in an aqueous carbonate solution, stirring and mixing, and then drying to obtain a solid mixture;

[0032] B. Heat the solid mixture obtained in step A to 800-900° C. for calcination under an inert atmosphere, and the calcined product is washed and dried to obtain nitrogen-rich hierarchical porous biochar.

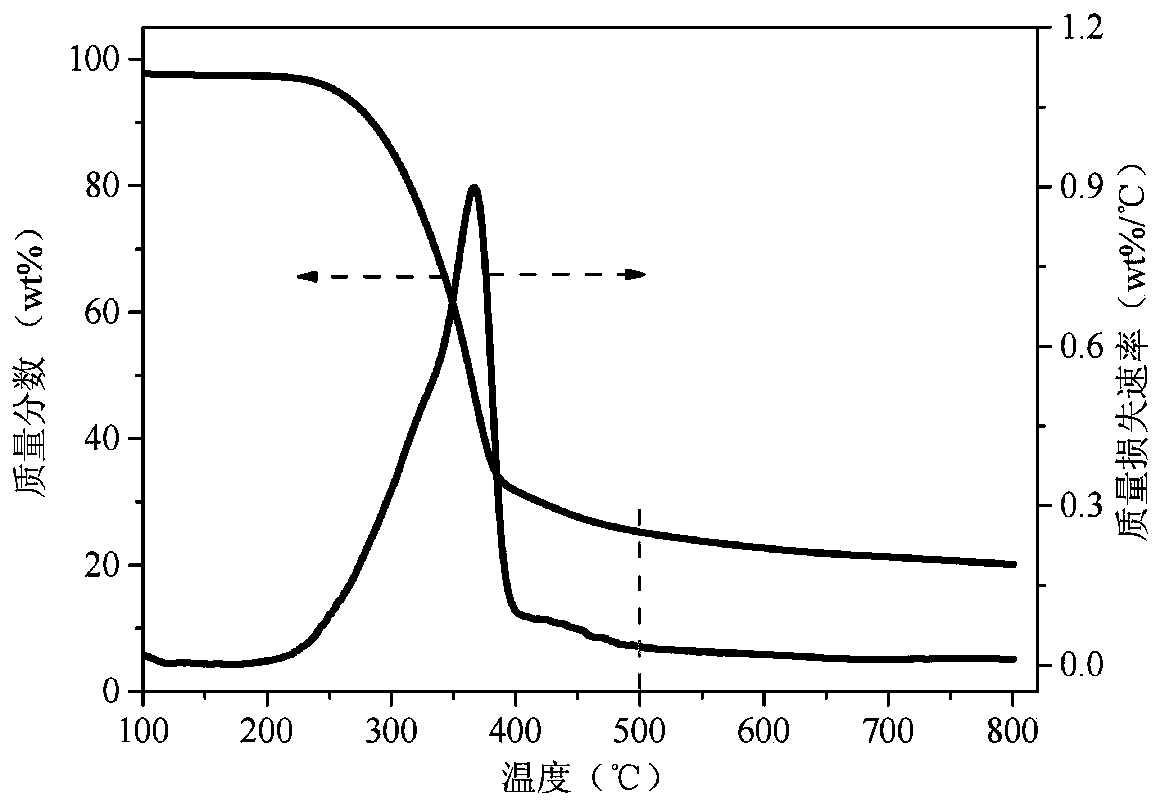

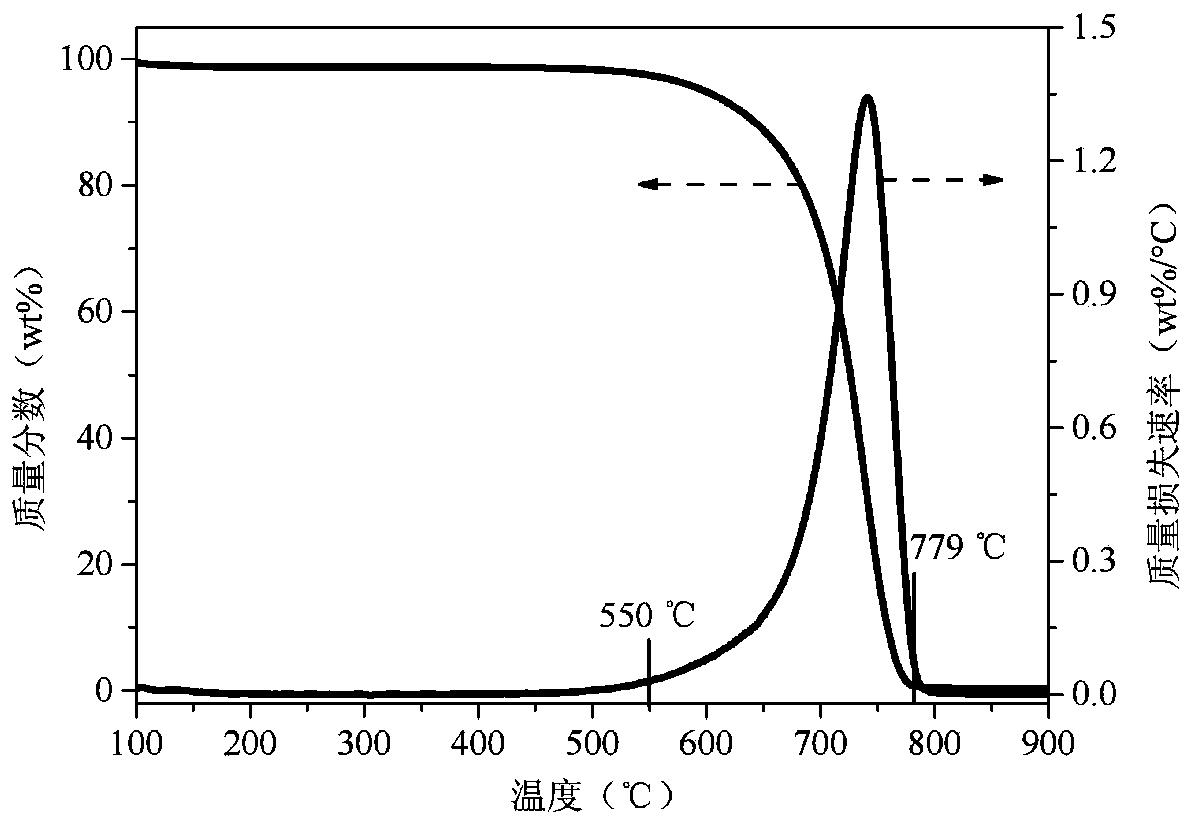

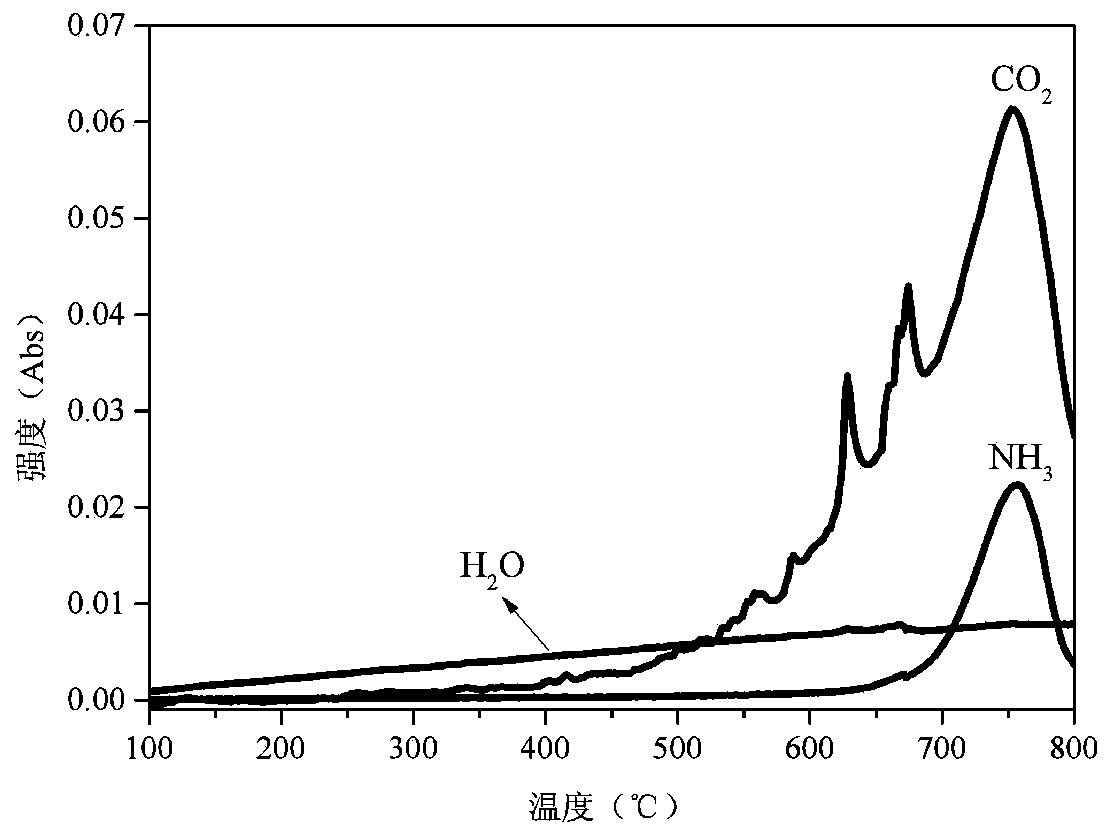

[0033] The inventor first studied the pyrolysis characteristics of biomass and carbon nitride, and found that the decomposition temperature of carbon nitride was equivalent to the carbonization temperature of biomass, so nitrogen-rich carbon nitride (CN) was used as a nitrogen doping agent, which was more effective. It is conducive to the efficient introduction of nitrogen-containing functional groups in biochar.

[0034] The biomass of the present invention comes from a wide range of sources, such as cypress wood chips, po...

Embodiment 1

[0043] Take 50g of sawdust and 50g of carbon nitride, mechanically crush them to a particle size of 100 mesh, place them in 250mL of potassium carbonate aqueous solution (containing 75g of potassium carbonate) and mechanically stir for 3 hours, and then dry the formed uniform turbid liquid at 80°C for 24h Obtain a solid mixture; under the protection of a nitrogen atmosphere, heat the dried solid mixture to 800°C at a heating rate of 5°C / min and keep it for 2 hours; the calcined product is washed with distilled water to neutrality and dried to obtain nitrogen Doped Hierarchical Porous Biochar (NKC).

[0044] The pyrolysis characteristics of wood chips and carbon nitride used in this embodiment are as follows: figure 1 with figure 2 As shown, the gas products released during the carbon nitride decomposition process are as image 3 As shown, the nitrogen adsorption isotherm of the prepared nitrogen-doped hierarchical porous biochar is as follows Figure 4 Shown, X-ray photoel...

Embodiment 2

[0058] The nitrogen-enriched biochar prepared in Example 1 was used as a catalyst to catalyze the oxidation of hydrogen sulfide at a low temperature. The experimental process was as follows: 0.30 g of biochar samples were packed in a fixed-bed reactor (diameter 10 mm), and 150 mL / min analog H 2 S waste gas, hydrogen sulfide was removed at 25 °C, and the desulfurization performance of biochar was evaluated; simulated H 2 S exhaust gas composition: H 2 S concentration 1000ppmv, O 2 The concentration is 10000ppmv, the relative humidity is 30%, and the rest is nitrogen. For the breakthrough curve of the experiment, see Image 6 .

[0059] Depend on Image 6 The breakthrough sulfur capacity calculated from the breakthrough curve is shown in Table 3:

[0060] Table 3 Breakthrough time and sulfur capacity of biochar for hydrogen sulfide removal

[0061] sample Penetration time (min) Breakthrough sulfur capacity (mg / g) C 8 6.8 KC 12 12.5 NC 19 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com