Method for efficiently producing sodium fluoride, aluminum fluoride and silicon tetrachloride by comprehensively utilizing sodium fluorosilicate

A technology of sodium fluorosilicate and silicon tetrachloride, applied in the fields of chemical industry and materials, can solve the problems of molten agglomeration of sodium fluorosilicate, small market capacity, addition of additives, etc., so as to reduce production costs, achieve good product quality, Improve the effectiveness of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

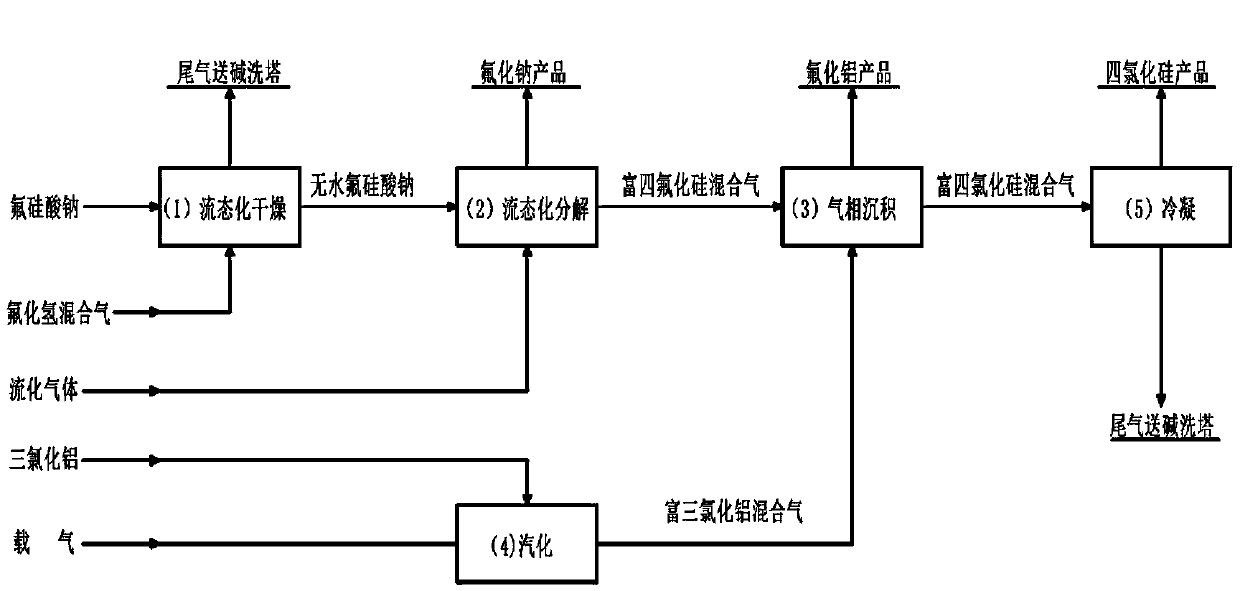

[0030] figure 1 It is a schematic flow chart of the method for comprehensively utilizing sodium fluorosilicate to efficiently produce sodium fluoride, aluminum fluoride and silicon tetrachloride according to the present invention.

[0031] combine figure 1 , a method for comprehensively utilizing sodium fluorosilicate to efficiently produce sodium fluoride, aluminum fluoride and silicon tetrachloride used in this embodiment, the method includes fluidized drying process 1, fluidized decomposition process 2, Vapor deposition process 3, vaporization process 4 and condensation process 5 are five processes, which are specifically carried out in the following steps:

[0032] 1) The sodium fluorosilicate raw material is firstly obtained through a fluidized drying process to obtain anhydrous sodium fluorosilicate, and the dry tail gas is sent to an alkali washing tower for treatment;

[0033] 2) Anhydrous sodium fluorosilicate is sent to fluidized decomposition process to obtain sod...

Embodiment 2

[0037] This embodiment adopts the method for comprehensively utilizing sodium fluorosilicate to produce sodium fluoride, aluminum fluoride and silicon tetrachloride described in embodiment 1, and the fluidized drying process 1 adopts a fluidized bed reactor, and the drying temperature is 0 °C, drying time 36h, the volume ratio of hydrogen fluoride in the hydrogen fluoride mixed gas is 0.1%, and the rest of the gas is purified nitrogen. In the fluidized decomposition process 2, a fluidized bed reactor is used, the decomposition temperature is 400° C., the residence time is 300 minutes, and the fluidization gas is purified nitrogen. The vapor phase deposition process 3 adopts a fluidized bed reactor, the reaction temperature is 200° C., and the molar ratio of aluminum trichloride to silicon tetrafluoride is 1.50. The aluminum trichloride and the carrier gas enter the vaporization process 4 together, the vaporization temperature is 150° C., the carrier gas is purified air, and th...

Embodiment 3

[0039] This embodiment adopts the method of comprehensively utilizing sodium fluorosilicate to produce sodium fluoride, aluminum fluoride and silicon tetrachloride as described in Example 1, and the fluidized drying process 1 adopts a fluidized bed reactor, and the drying temperature is 200 ℃, drying time 0.1h, the volume ratio of hydrogen fluoride in the hydrogen fluoride mixture gas is 15%, and the rest gas is purified air. In the fluidized decomposition step 2, a fluidized bed reactor is used, the decomposition temperature is 700° C., the residence time is 15 minutes, and the fluidization gas is purified air. The vapor phase deposition step 3 uses a fluidized bed reactor, the reaction temperature is 600° C., and the molar ratio of aluminum trichloride to silicon tetrafluoride is 1.34. The aluminum trichloride and the carrier gas enter the vaporization process 4 together, the vaporization temperature is 300° C., the carrier gas is purified nitrogen, and the aluminum trichlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com