Preparation method, product and application of hot-melt self-adhesive adhesive in the production of self-adhesive bandages

A self-adhesive and hot-melt technology, applied in the direction of adhesives, adhesive types, heat-activated films/sheets, etc., can solve the problems of high emulsion prices, unfriendly environment, skin allergies, etc., and save equipment investment and production space , The preparation process is simple, the effect of low skin irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

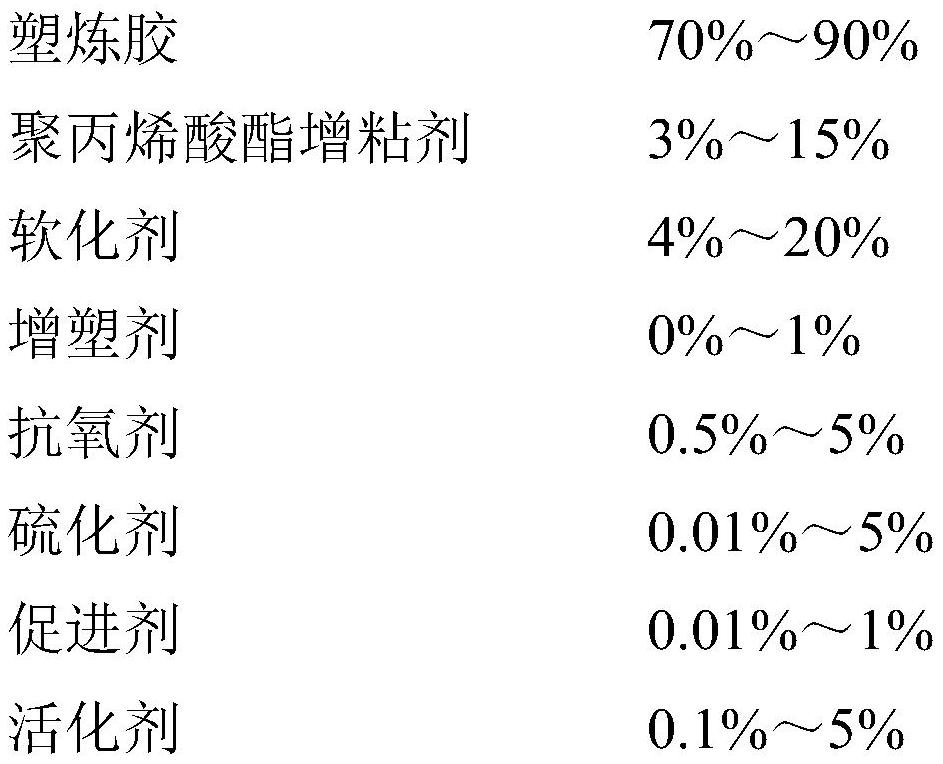

Method used

Image

Examples

Embodiment 1

[0054] Firstly, the polyisoprene rubber synthesized from the raw material is sliced, the double-roll mill is preheated, the roll temperature is kept between 55-65°C, the roll speed is controlled at 16-18r / min, and the speed ratio of the front and rear rolls is adjusted to 1. : 1.15~1.18, then add the sliced rubber into the open mill for masticating, thin pass 3 times, after the plasticized rubber is chopped by a shredder, it is sealed and stored for later use.

[0055] Then, add 109.50kg of raw materials methyl methacrylate, 790.00kg of isooctyl acrylate, 100.00kg of dioctyl adipate, and 0.50kg of benzoyl peroxide into the reaction kettle with a reflux condenser, start the stirrer, and heat The temperature of the reaction system is 85-90°C, and the reaction is maintained at this temperature. When the reaction becomes viscous, the heating is stopped (about 3 hours), and the reaction is completed. When the temperature is lowered to below 40°C, the material can be discharged to ...

Embodiment 2

[0060] Firstly, the polyisoprene rubber and styrene-butadiene rubber synthesized by the raw materials are sliced separately, the double-roll mill is preheated, the roller temperature is kept between 50-60°C, and the roller speed is controlled at 16-18r / min. Before and after adjustment The speed ratio of the rollers is 1:1.18~1.20, and then the sliced rubber is added to the open mill for mastication. The polyisoprene rubber is thinly passed 3 times, and the styrene-butadiene rubber is thinly passed 5 times. The plasticized rubber is cut After shredding with a shredder, keep it sealed for future use.

[0061] Then, 99.00 kg of methyl methacrylate, 560.00 kg of isooctyl acrylate, 140.00 kg of dodecyl methacrylate, 200.00 kg of dioctyl phthalate, and 1.00 kg of azobisisobutyronitrile were added to the reflux In the reaction kettle of the condenser, start the agitator, heat the temperature of the reaction system to 90-95°C, and maintain the reaction at this temperature, stop he...

Embodiment 3

[0066] Firstly, the raw materials synthesized polyisoprene rubber, SIS rubber and EPDM rubber were sliced separately, and the double-roll mill was preheated, the roller temperature was kept between 60-70°C, and the roller speed was controlled at 16-18r / min, adjust the speed ratio of the front and rear rollers to 1:1.20~1.25, and then add the sliced rubber into the open mixer for mastication. The polyisoprene rubber and SIS rubber are thinly passed 3 times, and the EPDM rubber is thinly passed. It can be passed 5 times. After the plasticized rubber is chopped by a shredder, it is sealed and stored for later use.

[0067] Then, the raw materials methyl methacrylate 103.00kg, butyl acrylate 559.75kg, dodecyl methacrylate 186.50kg, dioctyl phthalate 100.00kg, dioctyl sebacate 50.00kg, di-t-butyl Add 0.25 kg of base peroxide, 0.50 kg of azobisisobutyronitrile, etc. into the reaction kettle with reflux condenser, start the agitator, heat the temperature of the reaction system t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com