Method for treating cyclization wastewater generated in folic acid production process

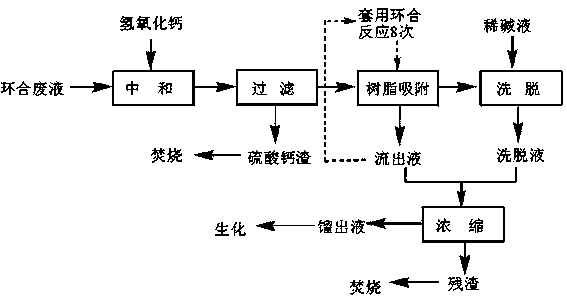

A technology of production process and treatment method, applied in the direction of neutralization water/sewage treatment, filtration treatment, adsorption water/sewage treatment, etc., can solve the problems of incomplete treatment process, increased waste water volume, high cost, etc., and achieve significant economic benefits and Social benefits, simple processing methods, and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Take 600 mL folic acid cyclization wastewater, wastewater components: wastewater COD value 10500 ppm, ammonia nitrogen 184 mg / L, SO 4 2- The content is 0.7%, Cl - content of 0.9%, waste water was placed in a 1000 mL three-necked flask, stirred and added calcium hydroxide aqueous solution, the pH was adjusted to 6-7, calcium sulfate precipitated, and the sulfate ions in the waste liquid were removed, and part of it could be taken away. Organic matter, calcium sulfate waste residue was filtered out, and the COD value of the filtrate was 8600 ppm, ammonia nitrogen 132 mg / L, SO 4 2- The content is 0.02%;

[0027] 2. Put 60 mL of resin LX-18 into the resin column (Φ20ⅹ300 mm) fixed by iron clips, pass 500 mL of the filtrate that has been filtered through the resin bed at a flow rate of 60 mL / h at room temperature, collect the effluent, and measure the effluent. The COD value of the liquid is 2030 ppm, and the ammonia nitrogen is 32 mg / L, meeting the requirements of th...

Embodiment 2

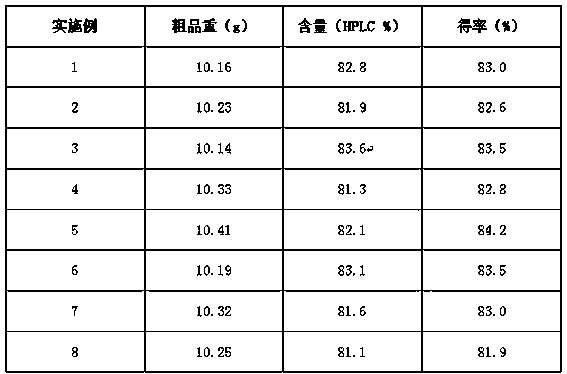

[0031] The effluent after resin adsorption has carried out 8 times of mechanical ring closure reactions altogether, figure 2 It is a statistical table of the results of the cyclization experiments applied mechanically for 8 times. It can be seen from the data in the table that the waste liquid has little effect on the yield and content of the cyclization after being treated 8 times and applied mechanically for 8 times. The content of chloride ions in the medium has reached 7.2%, so after 8 times of mechanical application, the waste liquid is no longer treated mechanically, and then the concentration device is used for subsequent treatment.

[0032] Take 500 mL of waste liquid and 350 mL of resin eluent after applying mechanically for 8 times, add them to a 1500 mL three-necked distillation bottle, distill until the bottom of the bottle becomes sticky, pour it out, and incinerate the residue; distillate 800 mL, COD The value is 930 ppm, which satisfies the condition of de-bioc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap