Hermetia illucens breeding method and hermetia illucens puparium composite material preparation method

A black soldier fly and pupal shell technology, applied in the field of materials, can solve the problems of resistance to drugs and the unused part of the pupa shell, etc., and achieve the effect of improving antibacterial effect, increasing yield, and promoting conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0047] Five groups of black soldier fly larvae were fed separately

[0048] (1) Starch waste, such as starchy food waste such as noodles, bread, steamed buns, and leftovers;

[0049] (2) distiller's grains;

[0050] (3) Straw;

[0051] (4) Meat;

[0052] (5) poultry manure;

[0053] Collect the pupal shells left by the adult black soldier flies with five feeding methods;

[0054] Prepare black soldier fly pupal shell powder in the following manner:

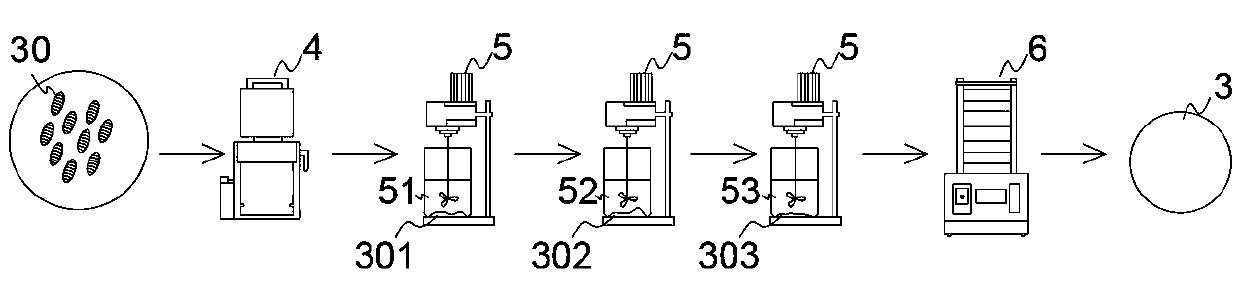

[0055] S1. After drying the black soldier fly pupal shell, grind it into powder by grinder 4;

[0056] S2. Add the powdery black soldier fly pupal shell in the low-concentration sodium hydroxide solution 51 of 3.5wt%, separate and filter after being stirred by the mixer 5; the effect of this step is mainly to remove the protein on the surface of the pupal shell;

[0057] S3. adding the powdered black soldier fly pupal shell through step S2 into the hydrochloric acid solution 52 of 12 normal concentration, stirring and then s...

specific Embodiment 2

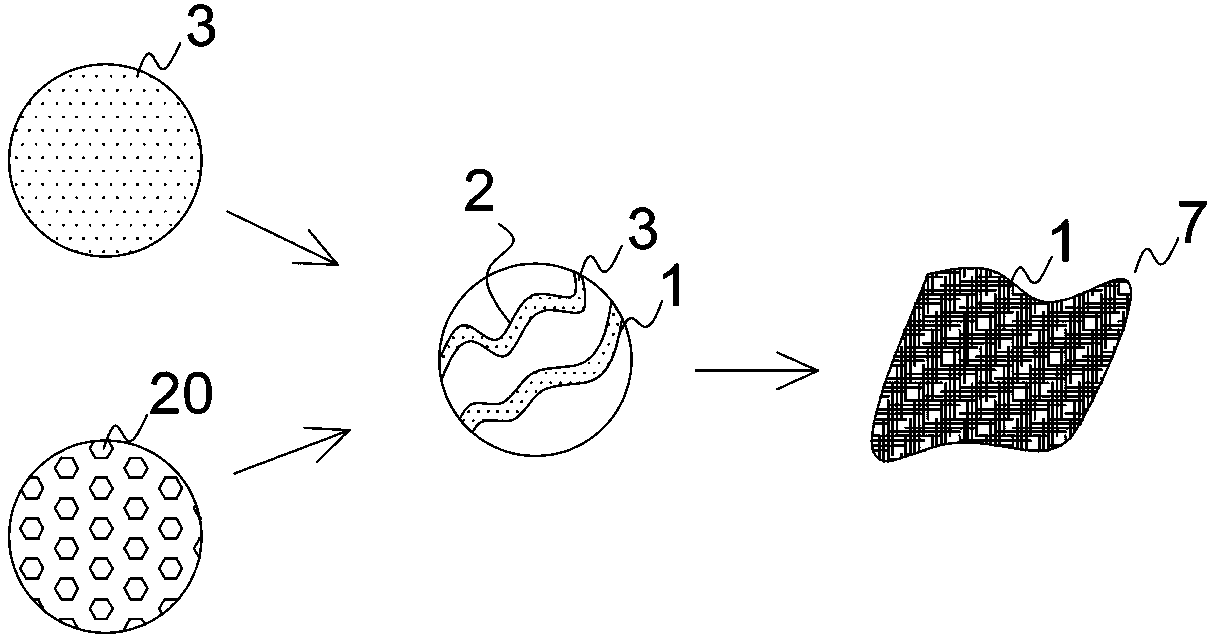

[0067] The black soldier fly chrysalis powder prepared in Example 1 was melt-blended with different polymer substrates such as polypropylene, polyenamine, polylactic acid, polyethylene terephthalate, etc. to prepare different The black soldier fly pupal shell polymer composite material, so that the black soldier fly pupal shell powder 3 can be evenly distributed in the polymer material 20, and the specific method is to mix the polymer base material powder and the black soldier fly pupal shell powder evenly Heat and melt to mix the two evenly.

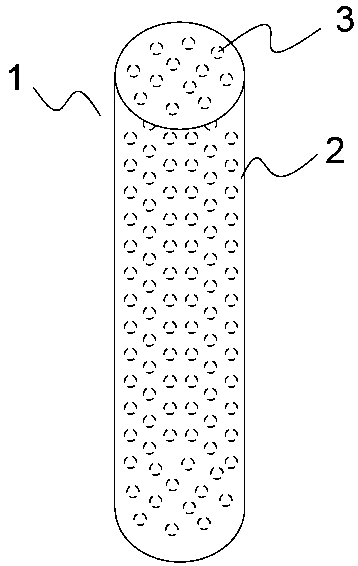

[0068] Then, it can be produced by spinning through thermoplastic equipment, such as figure 1 The black soldier fly pupal shell polymer composite fiber 1 shown can further make the obtained composite fiber into a non-toxic, safe, antibacterial, and breathable black soldier fly pupal shell polymer composite fiber by spinning, weaving or coating Black soldier fly pupal shell polymer composite fiber products with good mechanical propertie...

specific Embodiment 3

[0073] Dissolve 14.925 grams and 12 grams of carboxymethyl cellulose in 100 ml of aqueous solution, add 0.075 grams and 3 grams of black soldier fly pupal shell powder to the carboxymethyl cellulose aqueous solution, and disperse the powder in carboxymethyl cellulose with 1000 rpm high-speed stirring. In the methyl cellulose, several pieces of films were scraped with a scraper with a thickness of 600 um, dried in an oven for 8 hours, and black soldier fly pupal shell composite films with black soldier fly pupal shell contents of 0.5% and 20% were prepared respectively. The method of preparing the film can also be a casting method. After the powder is melted, it is melted and plasticized from the extruder, and extruded through the die of the slit die, so that the molten material is closely attached to the cooling roller, and after stretching, trimming , coiling and other processes made of sheet.

[0074] The specific test performance is shown in Table 3. The carboxymethyl cellu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com