Stannic dioxide/graphdiyne compound interface layer and preparation and application thereof

A technology of tin dioxide and graphdiyne, which is applied in the manufacture of tin oxide, graphite, semiconductor/solid-state devices, etc., can solve the problems of reducing the performance of perovskite solar cells, the interface layer is not dense, and the wettability is poor. Improve the effect of interface charge transfer efficiency, good conductivity, overall efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

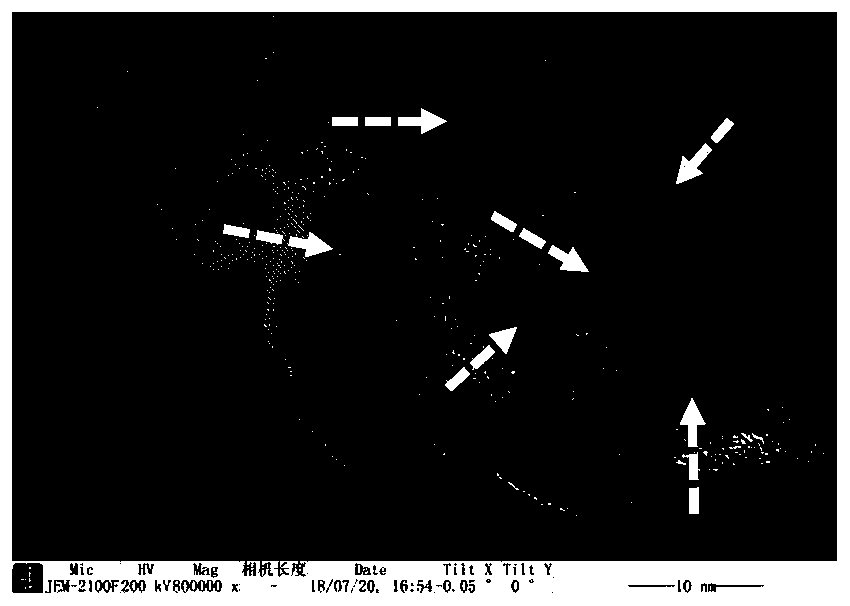

[0047] Preparation of graphyne / tin dioxide composite

[0048] Weigh 3.50 grams of tin chloride pentahydrate with a balance, put it into a 200 ml beaker, then measure 30 ml of absolute ethanol and 30 ml of deionized water, mix them evenly, and slowly inject them into the beaker with tin chloride pentahydrate in, stir to dissolve tin chloride pentahydrate; draw 22 milliliters of tetramethylammonium hydroxide with a pipette gun and pour it into a 100 milliliter beaker, then measure 38 milliliters of deionized water to dilute tetramethylammonium hydroxide to 60 milliliters; finally Inject 60 milliliters of diluted tetramethylammonium hydroxide solution into a beaker filled with tin chloride pentahydrate solution, stir until the solution is clear, then pour the mixed solution into a 150 milliliter hydrothermal reaction kettle liner, and water Heat reaction for 12 hours; after the reaction, the product was centrifuged and washed three times with absolute ethanol, and then vacuum-dri...

Embodiment 2

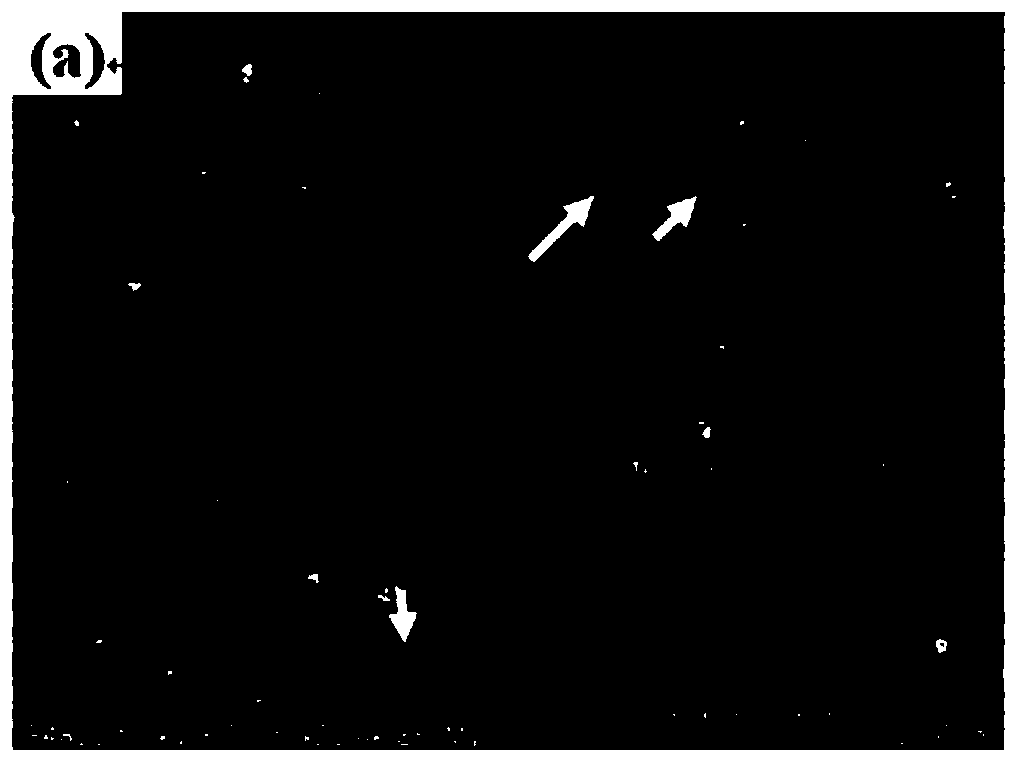

[0056] Fabrication of graphyne / tin dioxide composite interfacial layer perovskite batteries

[0057] Step 1): The glass sheet etched with indium tin oxide (ITO) electrodes on the surface is ultrasonically cleaned with detergent, deionized water, anhydrous acetone, and anhydrous isopropanol for 30 minutes each, and then the cleaned ITO The glass slides were cleaned with ozone plasma for 15 minutes, and then the ITO glass slides were blown dry for later use.

[0058] Step 2): spin-coat the P3CT-K solution prepared in advance on the ITO glass sheet, the spin-coating speed is 3000 rpm, and the spin-coating time is 1 minute, and then the glass sheet with the P3CT-K film is spin-coated at 140 ° C Heat on a hot plate for 30 minutes, then remove and cool to room temperature for later use.

[0059] The preparation process of P3CT-K solution is as follows: Weigh 40 mg of P3CT powder in a 4 ml screw bottle, then inject 4 ml of potassium hydroxide aqueous solution with a concentration of...

Embodiment 3

[0076] Example 3 is basically the same as Example 2, except that the perovskite cell preparation step 3 and the interdoping ratio of graphyne / tin dioxide in the corresponding interface layer are 1:3.

[0077] Step 3): Add 90 microliters of methylamine lead iodine precursor solution dropwise on the surface of the P3CT-K film prepared in step 2, spin-coat at 4000 rpm for 60 seconds, and drop 300 microliters of chlorobenzene solution in 8 seconds, Afterwards, the methylamine lead-iodine film was burned to caramel color on a heating plate at 60° C., and then burned to black on a heating plate at 80° C., wherein the heating time on the heating plate at 80° C. was 5 minutes.

[0078] The photoelectric performance test results show that the highest forward-scan efficiency of the fabricated perovskite cell is 19.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com