Titanium monoxide nano-material and preparation method and application thereof

A technology of titanium monoxide and nanomaterials, applied in the field of nanomaterial preparation and biomedicine, can solve the problems of poor controllability of component distribution, unsatisfactory treatment effect, complex synthesis method, etc., and achieve excellent biocompatibility and dispersion properties, regular shape, and high quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

[0041] The preparation of embodiment A1, TiO nanometer material

[0042] (1) 110 microliters of TiCl 4 Add to 20mL oleylamine and 10mL octadecene, heat to 140°C for 30min, the purpose is to remove the moisture and oxygen inside;

[0043] (2) Heat the above mixture to 320°C, keep it for 1 hour and then cool it to room temperature;

[0044] (3) The obtained product is precipitated by adding excess ethanol, and then repeatedly washed and centrifuged with dichloromethane to obtain hydrophobic TiO nanomaterials.

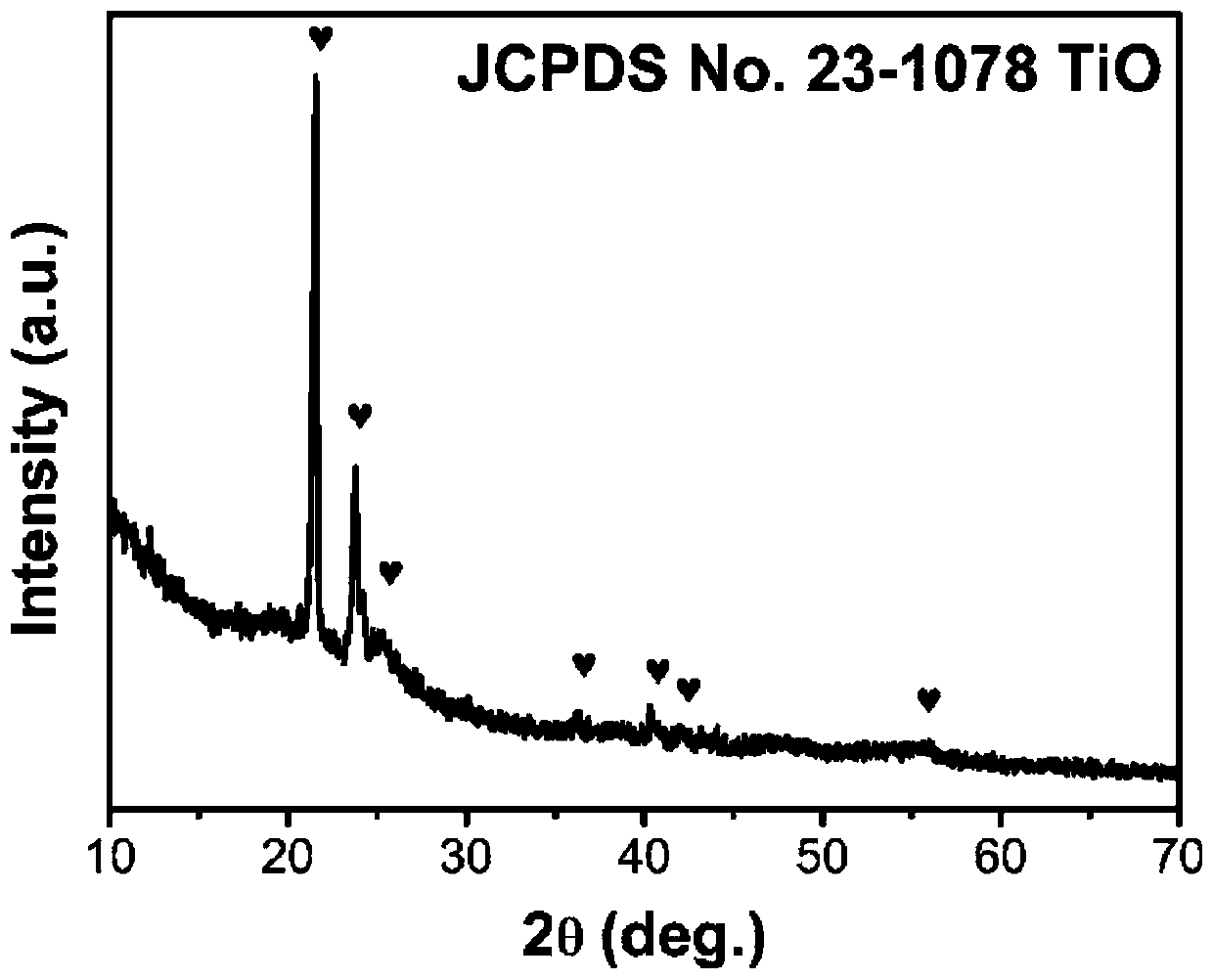

[0045] Such as figure 1 It is the X-ray diffraction pattern of the TiO nanomaterial obtained in Example 1, corresponding to the JCPDS standard card 23-1078, which proves that the synthesized product is TiO.

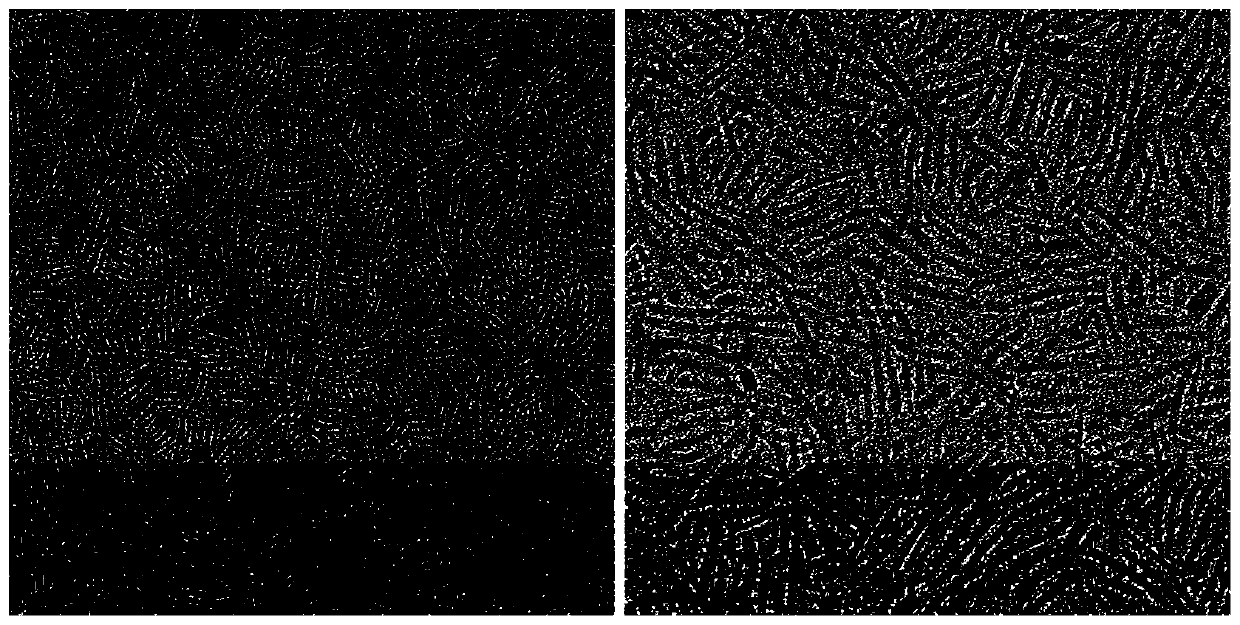

[0046] figure 2It is a transmission electron microscope image of the TiO nanomaterial obtained in Example A1. It can be seen from the image that the sample has a uniform appearance, and the appearance is a uniform rod shape with a size of 1-50 nm.

Embodiment A2

[0047] The preparation of embodiment A2, TiO nanometer material

[0048] (1) 110 microliters of TiCl 4 Add it to 30mL of diaminodiphenylmethane, heat to 140°C for 30min, the purpose is to remove the moisture and oxygen inside;

[0049] (2) Heat the above mixture to 220°C, keep it for 1 hour and then cool it to room temperature;

[0050] (3) The obtained product is precipitated by adding excess ethanol, and then repeatedly washed and centrifuged with dichloromethane to obtain hydrophobic TiO nanomaterials.

Embodiment B1

[0051] Example B1, the surface of TiO nanomaterials is modified with polyethylene glycol

[0052] Take a chloroform solution containing 5 mg of TiO nanomaterial synthesized in A1, then add a chloroform solution containing 25 mg of polyethylene glycol-grafted polymaleic anhydride-1-octadecene (C18PMH-PEG), and ultrasonically mix it completely for 30 minutes; Then perform vacuum rotary evaporation to remove the organic solvent inside to form a thin film; then add ultrapure water and ultrasonically disperse to obtain its aqueous solution; remove the excess polyethylene glycol molecules inside by centrifugal ultrafiltration to obtain polyethylene glycol-modified Aqueous solution of TiO(PEG-TiO) nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com