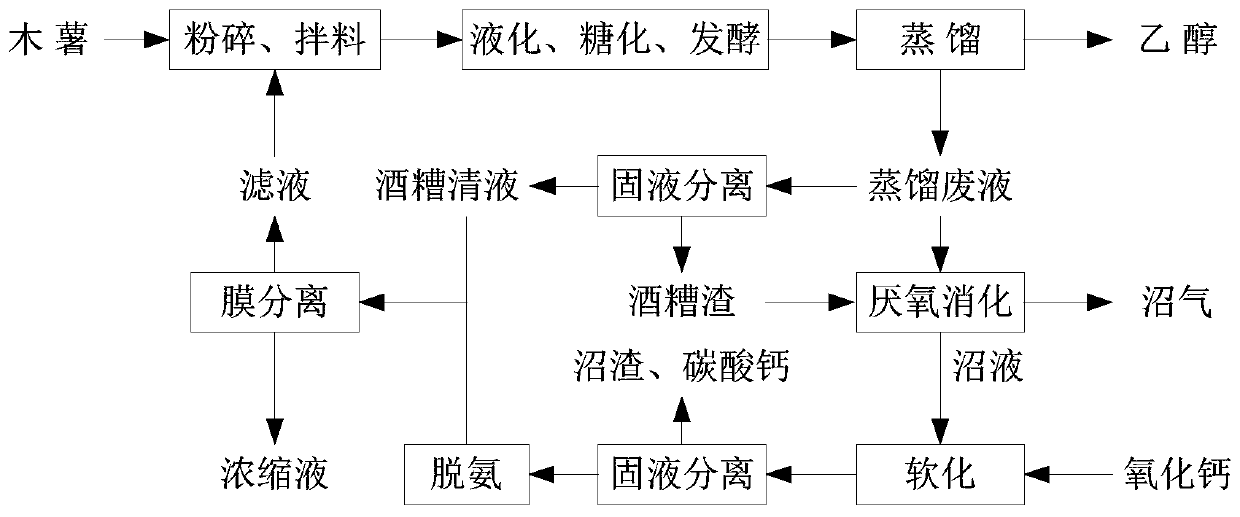

Method for recycling biogas slurry and vinasse clear liquid and producing ethanol

A distiller's lees clear liquid and recycling technology, applied in anaerobic digestion treatment, chemical instruments and methods, filtration treatment, etc., can solve the problems of reduced utilization rate of raw materials, expansion of membrane equipment filtration area, high cost of ammonia removal, etc., to reduce equipment Investment and operating costs, reducing deammonization operating costs, and solving the effects of fouling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

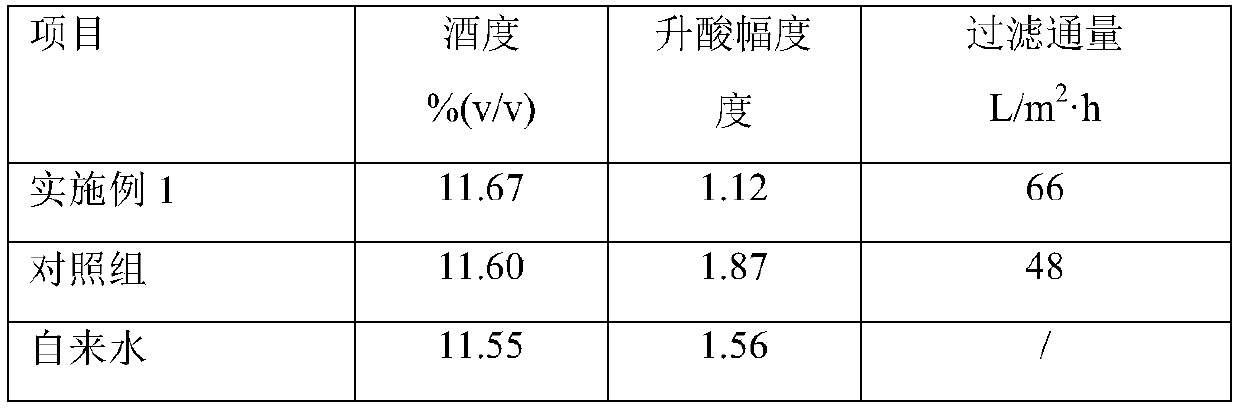

Embodiment 1

[0030] Calcium oxide is added to the biogas slurry obtained by anaerobic digestion, and the amount of calcium oxide added is controlled so that the pH value of the biogas slurry is 10.6. Calcium ions in the biogas slurry form calcium carbonate precipitation, and the calcium hardness in the biogas slurry is reduced to 20mg / L after softening treatment Below; the softened biogas slurry is naturally settled to remove calcium carbonate solid particles, and then the biogas slurry is sprayed into a negative pressure degasser with a vacuum degree of -0.095Mpa. Ammonia, the concentration of ammonia nitrogen in the biogas slurry after deamination is less than 500mg / L; the biogas slurry after deamination and distiller's grains liquid are mixed at a ratio of 60%:40% for membrane separation, and the membrane separation refers to the use of micro Membrane filtration, filtration pressure 0.1Mpa;

[0031] The filtrate obtained by membrane separation is returned to the crushing and mixing sect...

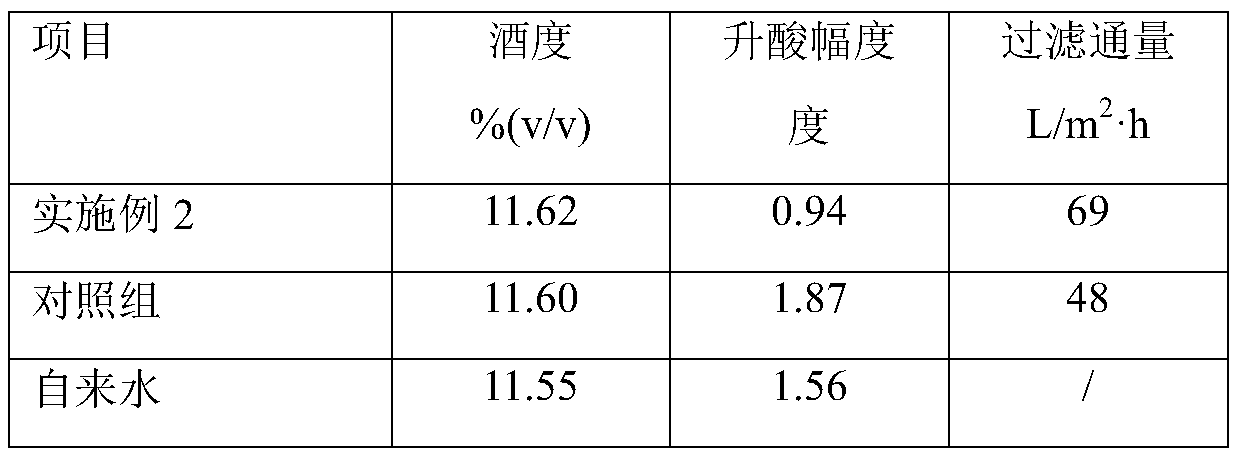

Embodiment 2

[0037] Add calcium oxide to the biogas slurry obtained from anaerobic digestion, control the amount of calcium oxide added so that the pH value of the biogas slurry is 11.0, calcium ions in the biogas slurry form calcium carbonate precipitation, and the calcium hardness in the biogas slurry is reduced to 18mg / L after softening treatment Below; the biogas slurry after softening treatment is filtered with a plate and frame to remove calcium carbonate solid particles, and then the biogas slurry is sprayed into a negative pressure degasser with a vacuum degree of -0.09Mpa. The temperature of the biogas slurry is 35°C and two-stage negative pressure is used. Deamination, the concentration of ammonia nitrogen in the biogas slurry after deamination is less than 500mg / L; the biogas slurry and distiller's grains after deamination are mixed at a ratio of 70%:30% for membrane separation, and the membrane separation refers to the use of a pore size of 0.25μm Microfiltration membrane filtra...

Embodiment 3

[0044] Calcium oxide is added to the biogas slurry obtained by anaerobic digestion, and the amount of calcium oxide added is controlled so that the pH value of the biogas slurry is 12.0. Calcium ions in the biogas slurry form calcium carbonate precipitation, and the calcium hardness in the biogas slurry is reduced to 16mg / L after softening treatment Below; the softened biogas slurry is centrifuged to remove calcium carbonate solid particles, and then the biogas slurry is sprayed into a negative pressure degasser with a vacuum degree of -0.08Mpa. The temperature of the biogas slurry is 45°C, and three-stage negative pressure is used. Deamination, the concentration of ammonia nitrogen in the biogas slurry after deamination is less than 500mg / L; the biogas slurry and distiller's grains after deamination are mixed at a volume ratio of 80%:20% for membrane separation, and the membrane separation refers to the use of a pore size of 0.45 μm Microfiltration membrane filtration, filtrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com