High-performance heat-preservation plastering mortar prepared from industrial solid waste and preparation method thereof

A technology for industrial solid waste and plastering mortar, which is applied in the preparation of high-performance thermal insulation plastering mortar and the field of high-performance thermal insulation plastering mortar. performance and durability, improved resource utilization, improved shrinkage cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

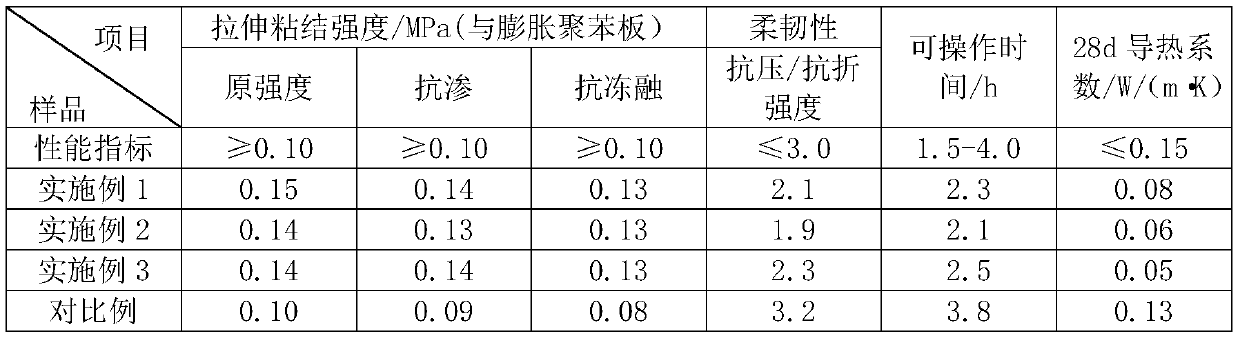

Examples

Embodiment 1

[0024] A high-performance thermal insulation plaster mortar prepared from industrial solid waste, the thermal insulation plaster mortar includes the following components in parts by weight: 10 parts of molybdenum tailings, 3 parts of phosphogypsum, 3 parts of sintering red mud, and 2 parts of S95 grade slag , 2 parts of Class II fly ash, 38 parts of ordinary Portland cement with a strength grade of 42.5, 2 parts of micro-expanded sulphoaluminate cement, 10 parts of natural sand, 10 parts of expanded perlite, 5 parts of alkali-resistant glass fiber, 5 parts of dispersion sol (including 18 parts of diatomaceous earth, 15 parts of ethylene-vinyl acetate copolymer, 60 parts of methyl methacrylate, 6.5 parts of titanate coupling agent, 0.5 parts of cumene hydroperoxide), hydroxypropyl 5 parts of methyl cellulose ether, 2 parts of water glass, 2 parts of starch ether, 1 part of polycarboxylate superplasticizer; the particle size of molybdenum tailings is 0.3mm; the particle size of s...

Embodiment 2

[0027]A high-performance thermal insulation plaster mortar prepared from industrial solid waste, the thermal insulation plaster mortar includes the following components in parts by weight: 15 parts of molybdenum tailings, 2 parts of phosphogypsum, 2 parts of sintering red mud, and 6 parts of S95 grade slag , 5 parts of Class II fly ash, 30 parts of ordinary Portland cement with a strength grade of 42.5, 1 part of micro-expanded sulphoaluminate cement, 6 parts of natural sand, 13 parts of expanded perlite, 4 parts of alkali-resistant glass fiber, 6 parts of dispersion sol (including 20 parts of diatomaceous earth, 14 parts of ethylene-vinyl acetate copolymer, 58 parts of methyl methacrylate, 7.6 parts of titanate coupling agent, 0.4 parts of cumene hydroperoxide), hydroxypropyl 6 parts of methyl cellulose ether, 1 part of water glass, 1 part of starch ether, 2 parts of polycarboxylate superplasticizer; the particle size of molybdenum tailings is 0.2mm; the particle size of steel...

Embodiment 3

[0030] A high-performance thermal insulation plaster mortar prepared from industrial solid waste, the thermal insulation plaster mortar includes the following components in parts by weight: 20 parts of steel slag sand, 6 parts of phosphogypsum, 5 parts of S95 grade slag, and 9 parts of II grade fly ash , 29 parts of ordinary Portland cement with a strength grade of 42.5, 1 part of micro-expanded sulphoaluminate cement, 5 parts of natural sand, 10 parts of expanded perlite, 1 part of alkali-resistant glass fiber, and 3 parts of dispersed colloidal sol (including diatom 17 parts of soil, 15 parts of ethylene-vinyl acetate copolymer, 60 parts of methyl methacrylate, 7.6 parts of titanate coupling agent, 0.4 parts of cumene hydroperoxide), 5 parts of hydroxypropyl methylcellulose ether , 2 parts of sodium silicate, 1 part of starch ether, 3 parts of polycarboxylic acid superplasticizer; the particle size of molybdenum tailings sand is 0.5mm; the particle size of steel slag sand is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com