A novel solid catalyst and its application in the preparation of 2,4-dimethyl-6-tert-butylphenol

A solid catalyst and a new type of technology, applied in catalytic reactions, preparation of organic compounds, catalysts for physical/chemical processes, etc., can solve the problems of insufficient consideration of the proportioning relationship, difficult recycling, difficult processing, etc., and achieve enhanced adhesion. The effect of focusing force and adhesion, excellent chemical stability, improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

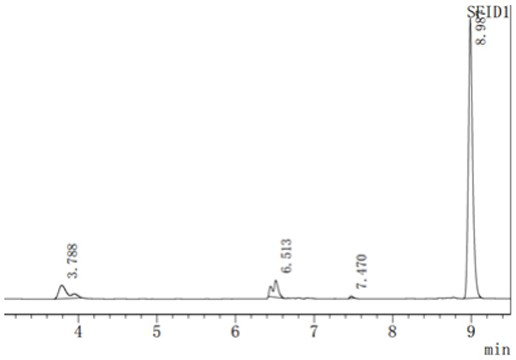

Image

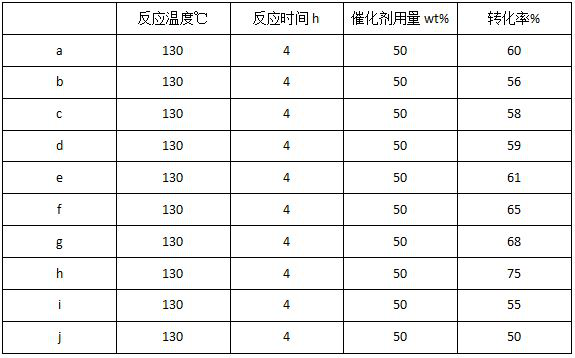

Examples

Embodiment 1

[0025] A preparation method of 2,4-dimethyl-6-tert-butylphenol, using 2,4-dimethylphenol and isobutylene as raw materials, catalyzed by a solid acid catalyst, to prepare 2,4-dimethyl-6-tert-butyl phenol.

[0026] The preparation method of the solid acid catalyst is as follows:

[0027] (1) Disperse 5g of graphite powder in 100ml of N-methylpyrrolidone (NMP), ultrasonically disperse it in a low-power ultrasonic device for 8h, and then centrifuge the obtained dispersion at 4000r / min for 10min to remove the unexfoliated graphite powder , to obtain graphene / N-methylpyrrolidone dispersion;

[0028] (2) Take 50ml, 0.5mg / ml of graphene / N-methylpyrrolidone dispersion, add styrene, ultrasonically disperse under low power for 3h, then add azobisisobutyronitrile, azobisisobutyronitrile and benzene The mass ratio of ethylene is 1:200, and the heating reaction is carried out for 40h under nitrogen atmosphere and mechanical stirring conditions;

[0029] (3) The product obtained after the...

Embodiment 2

[0037] A preparation method of 2,4-dimethyl-6-tert-butylphenol, using 2,4-dimethylphenol and isobutylene as raw materials, catalyzed by a solid acid catalyst, to prepare 2,4-dimethyl-6-tert-butyl phenol.

[0038] The preparation method of the solid acid catalyst is as follows:

[0039] (1) Disperse 5g of graphite powder in 100ml of N-methylpyrrolidone (NMP), ultrasonically disperse it in a low-power ultrasonic device for 8h, and then centrifuge the obtained dispersion at 4000r / min for 10min to remove the unexfoliated graphite powder , to obtain graphene / N-methylpyrrolidone dispersion;

[0040] (2) Take 80ml, 0.5mg / ml graphene / N-methylpyrrolidone dispersion, add NDZ-401 with a concentration of 1.0wt%, ultrasonically disperse for 3h under low power, then add azobisisobutyronitrile, The mass ratio of azobisisobutyronitrile to NDZ-401 is 1:200, and the heating reaction is carried out for 40h under nitrogen atmosphere and mechanical stirring conditions;

[0041] (3) The product ...

Embodiment 3

[0048] A preparation method of 2,4-dimethyl-6-tert-butylphenol, using 2,4-dimethylphenol and isobutylene as raw materials, catalyzed by a solid acid catalyst, to prepare 2,4-dimethyl-6-tert-butyl phenol.

[0049] The preparation method of the solid acid catalyst is as follows:

[0050] (1) Disperse 10g of graphite powder in 150ml of N-methylpyrrolidone (NMP), ultrasonically disperse it in a low-power ultrasonic device for 12h, and then centrifuge the obtained dispersion for 10min at 4200r / min to remove the unexfoliated graphite powder , to obtain graphene / N-methylpyrrolidone dispersion;

[0051] (2) Take 100ml, 0.5mg / ml of graphene / N-methylpyrrolidone dispersion, add KH560, ultrasonically disperse for 3h under low power, then add azobisisobutyronitrile, the mixture of azobisisobutyronitrile and KH560. The mass ratio is 1:200, and the heating reaction is carried out for 40h under the condition of nitrogen atmosphere and mechanical stirring;

[0052] (3) The product obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com