Two-dimensional MOFs nanosheet derived hybrid capacitor full-electrode material

A technology for hybrid capacitors and electrode materials, applied in the directions of hybrid capacitor electrodes, hybrid capacitors, capacitors, etc., can solve the problems of increased redox activity, surface defects, easily damaged structure, low content of heteroatoms, etc., and achieves good commercial value. The effect of outstanding chemical properties and high nitrogen atom content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of cathode materials for hybrid capacitors derived from two-dimensional MOFs nanosheets:

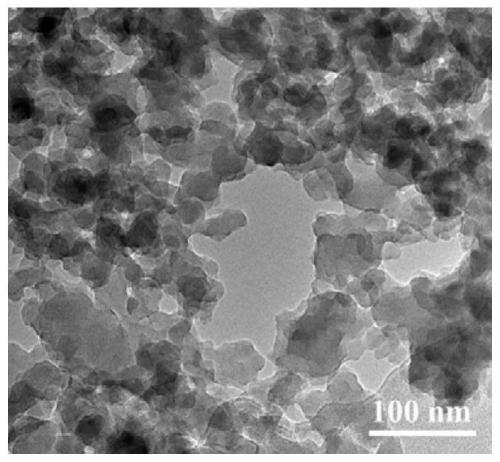

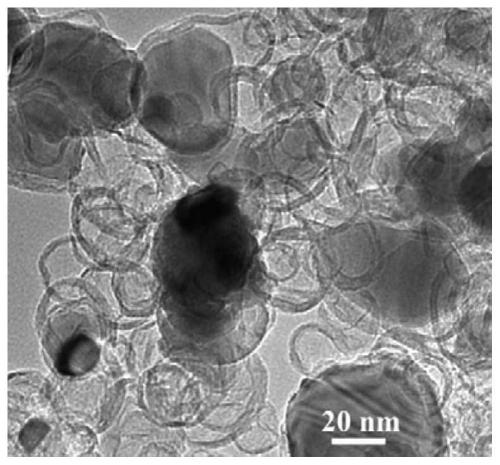

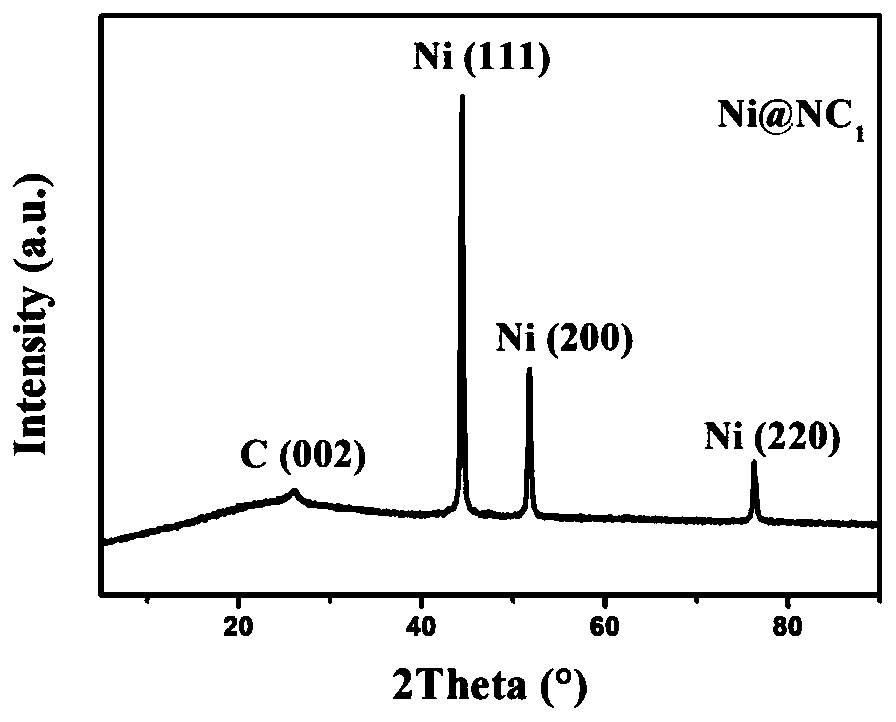

[0046] Prepare potassium 3-amino-1,2,4-triazole-5 carboxylate (3-amino-1,2,4-triazole-5-carboxylic acid and potassium hydroxide in a molar ratio of 1:1 ) And nickel acetate are added in a molar ratio of 3:2 to 20mL of water / ethanol mixed solvent (the volume ratio of water to ethanol is 1:1), and then added dropwise to 10mL of 0.012g / mL polyvinylpyrrolidone (PVP) aqueous solution, Among them, the mass ratio of nickel acetate to PVP is 1:3; first ultrasonic dispersion for 10 minutes, then stirring for 60 minutes, centrifugation, ethanol washing 3-5 times, ethanol washing can not only make the filter cake better dispersion, but also It is easier to dry to obtain a powder material, and the obtained powder material is not easy to bond, and dried at 80°C for 12 hours to obtain a two-dimensional MOFs nanosheet material. The scanning electron microscope (SEM) spectrum of the two...

Embodiment 2

[0054] Preparation of cathode materials for hybrid capacitors derived from two-dimensional MOFs nanosheets:

[0055] Prepare potassium 3-amino-1,2,4-triazole-5 carboxylate (3-amino-1,2,4-triazole-5-carboxylic acid and potassium hydroxide in a molar ratio of 1:1 ) And nickel acetate at a molar ratio of 2:1 to 30mL of water / ethanol mixed solvent (the volume ratio of water to ethanol is 1:1), and add dropwise to 10mL of 0.008g / mL polyvinylpyrrolidone (PVP) aqueous solution. , The mass ratio of nickel acetate to polyvinylpyrrolidone is 1:5; first ultrasonic for 30 minutes, then stirring for 60 minutes, then centrifugation, washing with ethanol 3–5 times, and drying at 60°C for 10 hours to obtain two-dimensional MOFs nanosheet materials.

[0056] Weigh 200 mg of MOFs nano-sheet material, grind it into a fine powder with an agate mortar, spread it evenly in a corundum crucible, place it in a tube furnace, and heat it up from room temperature to 850°C at a heating rate of 3°C / min, at a te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com