A preparation method of monodisperse high-performance quantum dot fluorescent microspheres

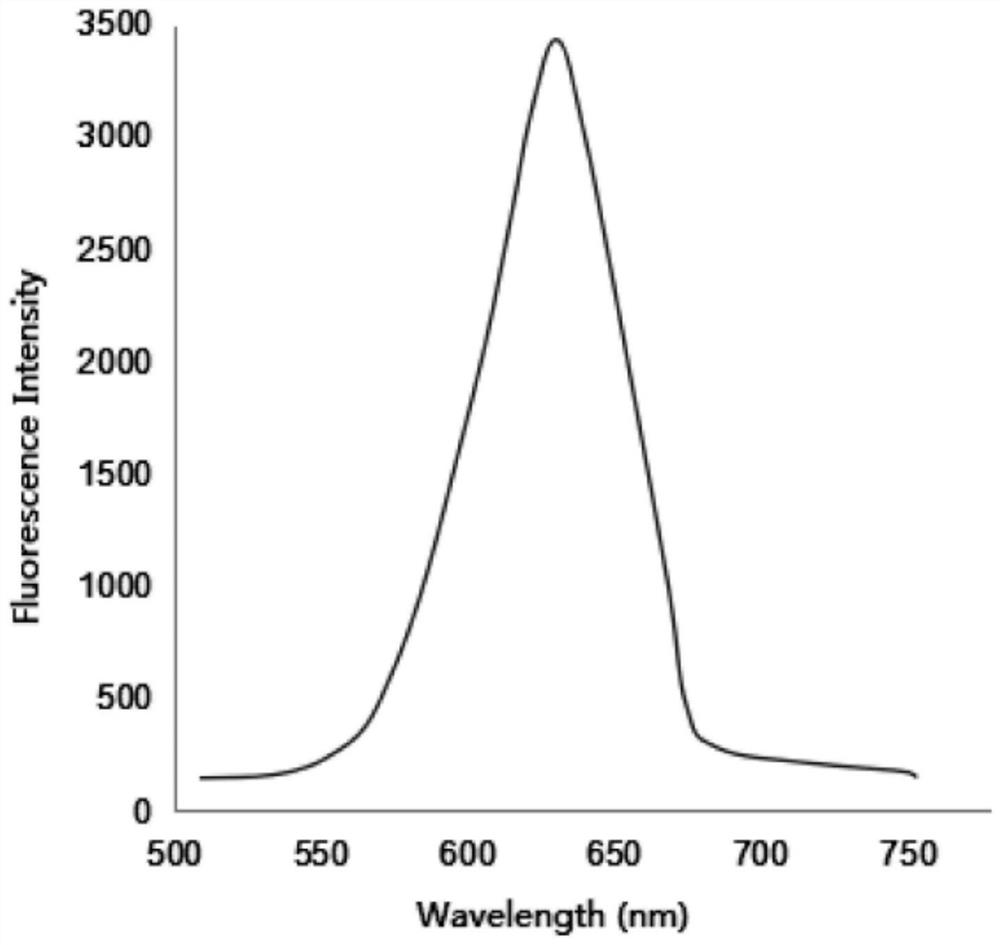

A fluorescent microsphere and quantum dot technology, applied in chemical instruments and methods, luminescent materials, nano-optics, etc., can solve the problems of the influence of surface properties and fluorescent characteristics, the limited luminous ability of a single quantum dot, and the instability of long-term storage. Avoid non-uniformity, uniform size, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing monodisperse high-performance quantum dot fluorescent microspheres, comprising the following steps:

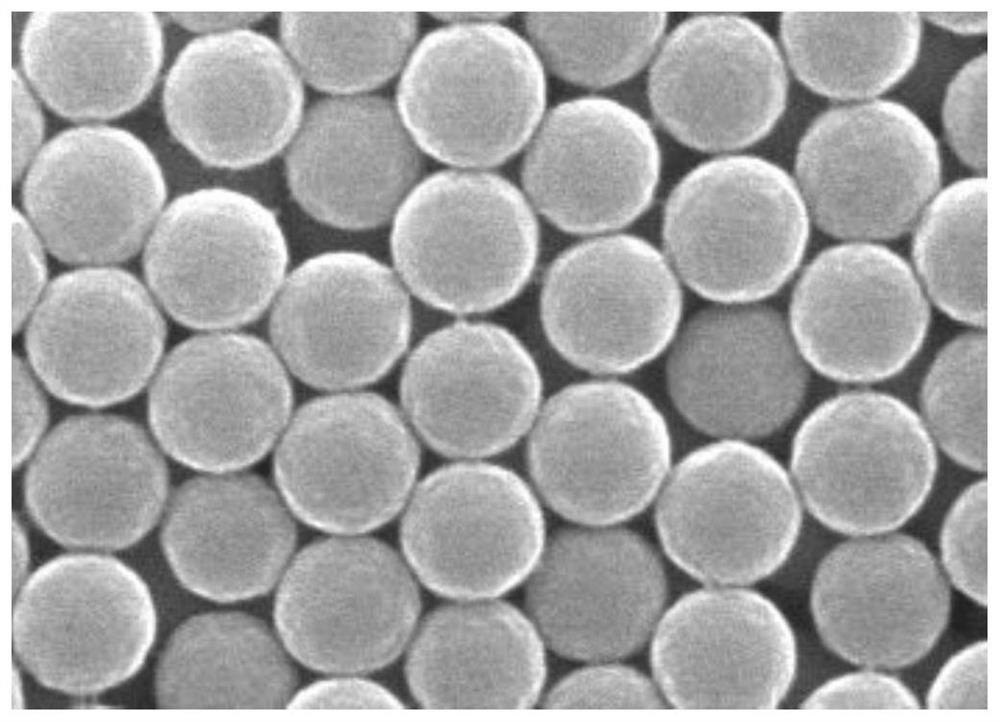

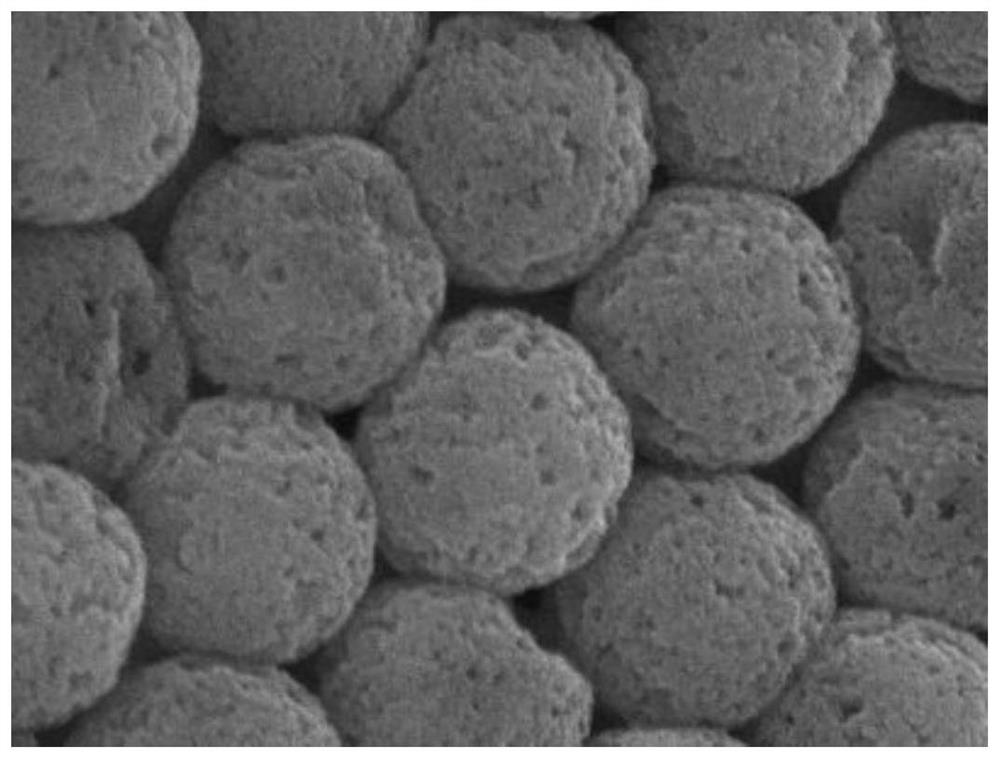

[0037] 1) Polystyrene seed microspheres are synthesized by free radical polymerization; prepared by free radical polymerization, including emulsion polymerization, soap-free emulsion polymerization or dispersion polymerization, by adjusting system parameters, such as monomer dosage, initiator dosage, emulsifier / Dispersant type, reaction medium, etc., control the size of the microspheres at 0.5-3um;

[0038] Specifically: in a water bath at 60-75°C, add monomer styrene into the reaction medium dissolved with emulsifier / dispersant, mechanically stir (100-300rpm), add 0.1-2% initiator of total monomer mass Dissolving and polymerizing for 7-24 hours to obtain polystyrene seed microspheres. Among them, the emulsifier / dispersant is sodium lauryl sulfate, sodium dodecylbenzenesulfonate, polyvinylpyrrolidone, polyvinyl alcohol, and the like. The react...

Embodiment 1

[0048] Weigh 0.4g of anhydrous sodium carbonate and 0.4g of potassium persulfate and ultrasonically dissolve them in 500g of deionized water. After the dissolution is complete, add them to a four-neck flask, add 30g of styrene monomer to it, stir mechanically at 200rpm, and place them in a constant temperature water bath at 70°C Reaction 10h. The polystyrene seed microspheres were obtained by centrifuging with ethanol and deionized water successively.

[0049] Weigh 10 g of the polystyrene seed microspheres prepared above, ultrasonically disperse them in 1500 g of 0.5% polyvinyl alcohol solution by mass dispersion, add them into a four-neck flask, keep the constant temperature water bath at 35° C., and mechanically stir at 120 rpm. Weigh 56g of styrene, 7g of aminostyrene, 7g of divinylbenzene, 10g of toluene, and 1.4g of azobisisobutyronitrile in a beaker. After ultrasonic dissolution, add 600g of dodecylsulfuric acid containing 0.2% by mass Sodium and polyvinyl alcohol aque...

Embodiment 2

[0054] Weigh 2 g of polyvinylpyrrolidone and ultrasonically dissolve it in 180 g of absolute ethanol, add it to a four-neck flask, add 20 g of styrene monomer, stir mechanically at 200 rpm, and react in a constant temperature water bath at 70°C for 24 hours. The polystyrene seed microspheres were obtained by centrifuging with ethanol and deionized water successively.

[0055] Weigh 10 g of the polystyrene seed microspheres prepared above, ultrasonically disperse them in 1500 g of 0.5% polyvinyl alcohol solution by mass dispersion, add them into a four-neck flask, keep the constant temperature water bath at 35° C., and mechanically stir at 120 rpm. Weigh 56g of styrene, 7g of aminostyrene, 7g of divinylbenzene, 20g of dibutyl phthalate, and 1.4g of azobisisobutyronitrile in a beaker. After ultrasonically dissolving, add it to 600g of sodium lauryl sulfate and polyvinyl alcohol aqueous solution with a mass fraction of 0.2%, and emulsified under high-pressure homogenization to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com