Method for one-pot synthesis of regular-morphology sulfide-TiO2 composite nanostructure by solvothermal method and application thereof

A technology of composite nanostructure and solvothermal method, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc. There are many factors affecting the method, so as to achieve the effect of improving photocatalytic performance, regular product morphology, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

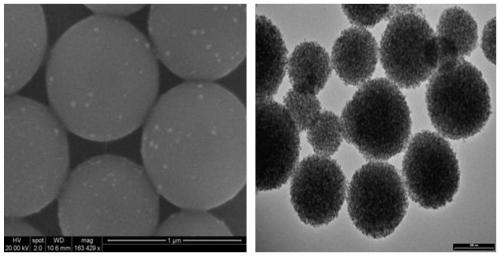

[0049] Example 1: One-pot synthesis of regular shape sulfide-TiO with a mass percentage of 1% by solvothermal method 2 Composite nano solid spheres, the specific steps are as follows:

[0050] 1g of titanium compound (this experiment is TiS 2 ) into 50mL of ethylene glycol solution containing 0.0117g metal salt (this experiment is cadmium nitrate ethylene glycol solution), and then add a certain amount of ammonium fluoride to it to make the solution pH ≈ 3-4, and magnetically stir for 0.5h Finally, the mixed solution was transferred to a 100mL autoclave liner, sealed and placed in an oven at 200°C for 12 hours. After the reaction was completed, it was naturally cooled to room temperature, and the obtained precipitate was washed with absolute ethanol and deionized water several times until the eluate was neutral (pH=7). % sulfide-TiO 2 One-component composite nano-solid sphere CdS-TiO 2 , denoted as S1, where 1% by mass is sulfide and TiO 2 The mass ratio of the specific e...

Embodiment 2

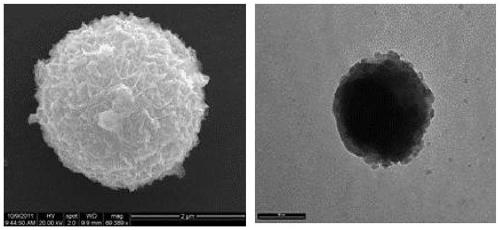

[0057] Example 2: Solvothermal one-pot synthesis of regular shape sulfide-TiO with a mass percentage of 2% 2 Composite nano solid spheres are prepared by the following method:

[0058] 1g TiS 3 Add 50mL of ethylene glycol solution containing 0.0177g of cadmium acetate into a polytetrafluoroethylene beaker, and then add a certain amount of ammonium chloride to it to make the solution pH ≈ 3-4. After magnetic stirring for 0.5h, transfer the mixed solution to 100mL In the liner of the high-pressure reactor, after sealing, place it in an oven at 200°C for 12 hours. After the reaction was completed, it was naturally cooled to room temperature, and the obtained precipitate was washed several times with absolute ethanol and deionized water until the eluate was neutral (pH=7). After vacuum drying at 60°C for 12 hours, a mass percent of % sulfide-TiO 2 One-component composite nano-solid sphere CdS-TiO 2 , denoted as S6.

[0059] The ethylene glycol solution of above-mentioned cadm...

Embodiment 3

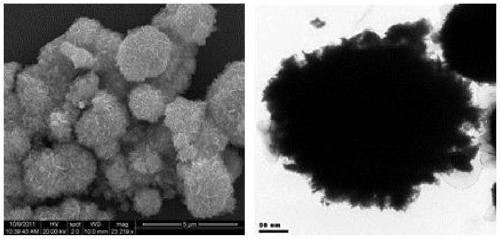

[0063]Example 3: One-pot synthesis of regular shape sulfide-TiO with a mass percentage of 3% by solvothermal method 2 Nano hollow sphere / hollow box is prepared by the following method:

[0064] 1g TiS 2 Add 50mL of ethylene glycol solution containing 0.0273g of cadmium chloride into a polytetrafluoroethylene beaker, and then add a certain amount of ammonium chloride to it to make the solution pH ≈ 3-4, and after magnetic stirring for 0.5h, transfer the mixed solution to Place in a 100mL autoclave liner, seal and place in an oven at 200°C for 12 hours. After the reaction was completed, it was naturally cooled to room temperature, and the obtained precipitate was washed with absolute ethanol and deionized water several times until the eluate was neutral (pH=7). After vacuum drying at 60° C. for 12 hours, the obtained precipitate was 3% by mass. The composite nano-solid box CdS-TiO 2 , denoted as S11.

[0065] The ethylene glycol solution of the above-mentioned cadmium chlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com