Method for recycling positive-negative electrode mixed material of waste ternary lithium-ion battery

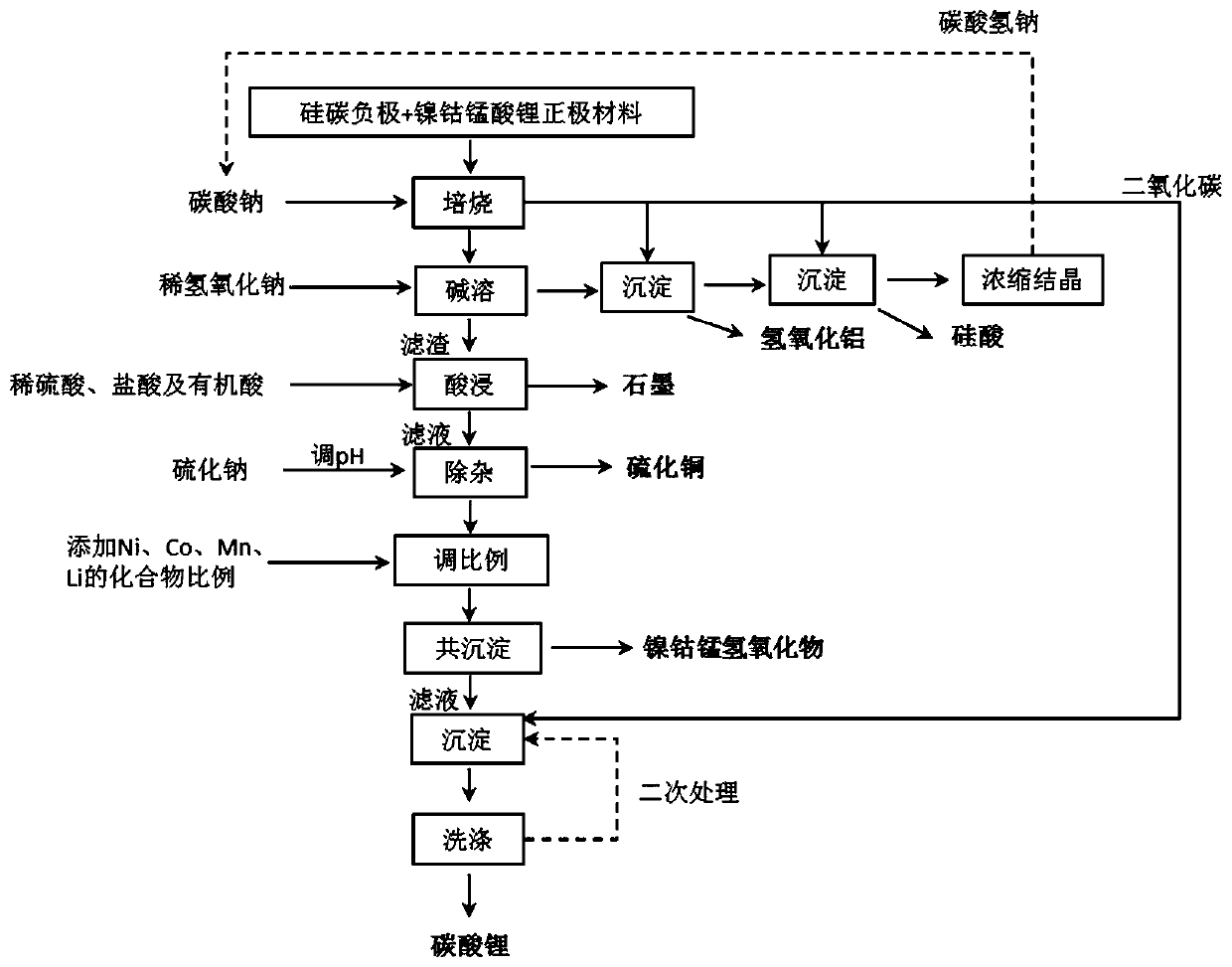

A technology of lithium-ion batteries and mixed materials, which is applied in the field of recycling waste ternary lithium-ion battery positive and negative mixed materials, can solve the problems of not involving the recovery of negative electrode materials, large acid and alkali consumption, and difficulties in the treatment of three wastes, so as to avoid leaching The effect of reducing the efficiency, effective recycling, and shortening the dismantling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] S1 discharges the used lithium-ion battery through a charge-discharge machine for about 4 hours (multiple discharges to ensure that the battery voltage is less than 1V), and then automatically disassemble and separate the positive and negative mixed powders through mechanical crushing, magnetic separation, screening and other methods , Battery case, copper foil, aluminum foil and diaphragm, the battery case, copper foil, aluminum foil and diaphragm are directly recycled after disassembly;

[0062] S2 mixes the mixed powders of positive and negative electrodes separated in step S1 with sodium carbonate according to the molar ratio of sodium carbonate to lithium nickel cobalt manganate of 0.3, and then puts them in a ball mill, calcined under nitrogen for 2 hours at a temperature of 800 ℃, and recovered at the same time The carbon dioxide produced by the reaction is cooled with the furnace.

[0063] S3 Put 800g of the mixture roasted in step S2 into 8L of dilute alkali solutio...

Embodiment 2

[0081] S1 discharges the waste lithium-ion battery in salt water for about 3 hours, and then automatically disassembles it through mechanical crushing, magnetic separation, screening and other methods to separate the positive and negative mixed powder, battery casing, copper foil, aluminum foil and diaphragm. The battery shell, copper foil, aluminum foil and diaphragm are directly recycled after dissolution;

[0082] S2 mixes the mixed powder of positive and negative electrodes separated in step S1 with sodium carbonate according to the molar ratio of sodium carbonate to lithium nickel cobalt manganese oxide of 0.2, and then puts them in a ball mill, and calcines under nitrogen for 1 hour at a calcination temperature of 850°C and recovers at the same time The carbon dioxide produced by the reaction is cooled with the furnace.

[0083] S3 Put 1.2 kg of the mixture roasted in step S2 into 10L of a dilute alkali solution with a concentration of 0.1 mol / L, react for 2 hours at room tem...

Embodiment 3

[0099] S1 discharges the used lithium-ion battery through a charge-discharge machine for about 4 hours (multiple discharges to ensure that the battery voltage is less than 1V), and then automatically disassemble and separate the positive and negative mixed powders through mechanical crushing, magnetic separation, screening and other methods , Battery case, copper foil, aluminum foil and diaphragm, the battery case, copper foil, aluminum foil and diaphragm are directly recycled after disassembly;

[0100] S2 mixes the mixed powder of positive and negative electrodes separated in step S1 with sodium carbonate according to the molar ratio of sodium bicarbonate to lithium nickel cobalt manganate of 0.12, and then puts them in a ball mill and calcines under nitrogen for 1 hour at a calcination temperature of 860°C. The carbon dioxide produced by the reaction is recovered and cooled with the furnace.

[0101] S3 Put 1.5kg of the mixture roasted in step S2 into 10L of dilute alkali soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com