A kind of cathode material of modified lithium ion battery coated with strong electronegative organic layer and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of battery cycle performance not being greatly improved, active material lattice falling off, etc., to achieve suppression of side reactions, cycle Performance improvement and conductivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

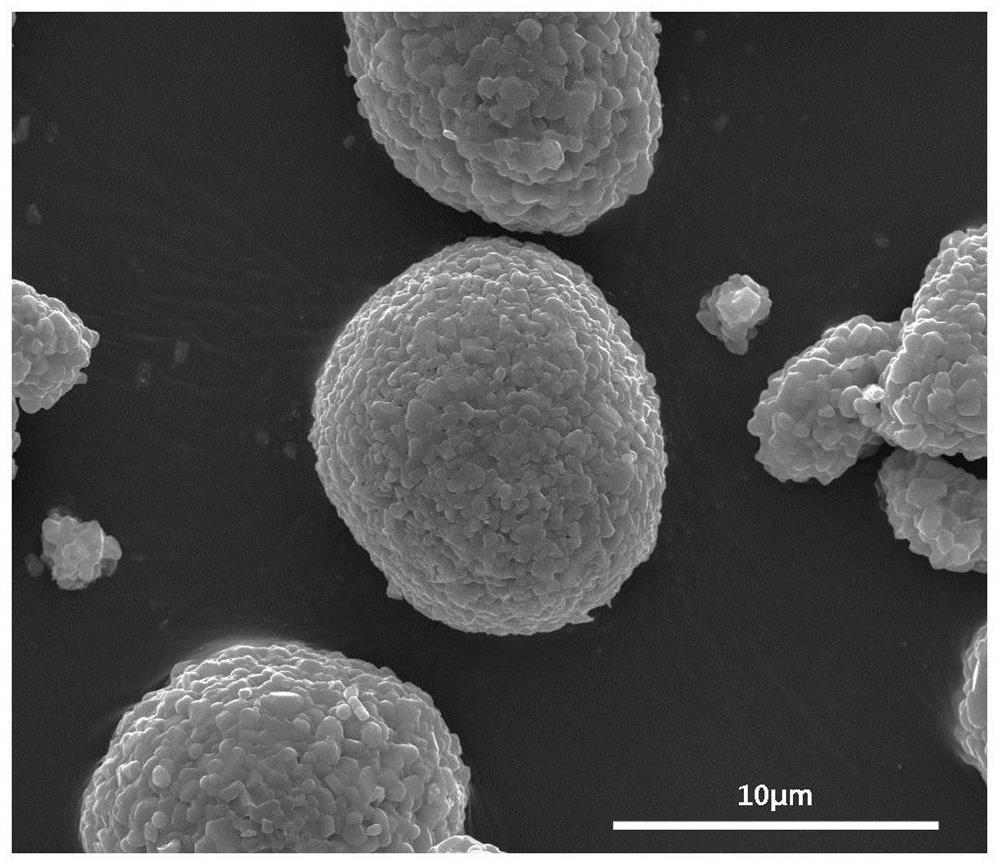

[0024] Accurately weigh 0.1 g of acetoacetate ethylene glycol methacrylate, LiNi 0.6 Co 0.2 Mn 0.2 O 2 5g was dissolved in 25ml of anhydrous acetonitrile, stirred for 1 hour at 60°C under an argon protective atmosphere, 0.001g of azobisisobutyronitrile initiator was added to the mixture, and the mixture was stirred at 60°C for 4 hours, using a rotary evaporator. The organically coated powder was collected and dried under vacuum for 12 h to obtain a sample with a coating amount of 2 wt%.

[0025] Weigh 0.16g of the obtained sample and raw material, respectively mix with 0.02g of conductive carbon black and 0.02g of PVDF, mix in a planetary mixer for 6min, add 500μLNMP, and prepare a slurry with a certain viscosity. Coat the prepared slurry on aluminum foil, dry it in a vacuum oven at 80°C, and use a hole puncher to make an electrode sheet with a diameter of 12 mm. LiTFSI / LiBOB / LiPF 6 , its molar ratio is 6:4:0.05 (the solvent is EC / EMC, its mass ratio is 4:6) and the elect...

Embodiment example 2

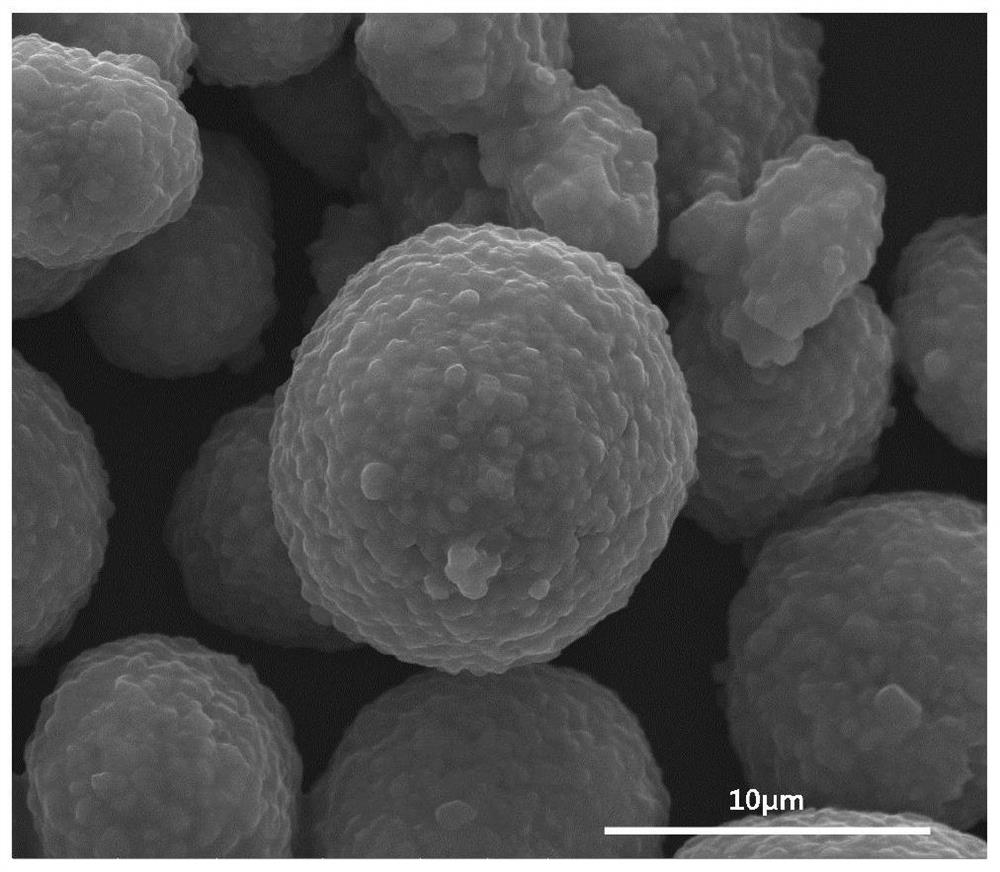

[0032] Accurately weigh 0.15 g of acrylic acid-2-cyanoethyl ester, LiNi 0.6 Co 0.2 Mn 0.2 O 2 5g and 0.001 azobisisobutyronitrile were dissolved in 25ml of anhydrous acetonitrile, and after stirring for 1 h at 60°C under an argon protective atmosphere, 0.001 azobisisobutyronitrile initiator was added to the mixture, and the stirring was continued for 4h at 60°C. After that, the organically coated powder was collected by a rotary evaporator, and dried in vacuum for 12 h to obtain a sample with a coating amount of 3 wt%.

[0033] Weigh 0.16g of the obtained sample and raw material, respectively mix with 0.02g of conductive carbon black and 0.02g of PVDF, mix in a planetary mixer for 6min, add 500μLNMP, and prepare a slurry with a certain viscosity. Coat the prepared slurry on aluminum foil, dry it in a vacuum oven at 80 °C, and use a punch to make an electrode sheet with a diameter of 12 mm, with 1 mol / L LiPF 6 (The solvent is EC / EMC, and its mass ratio is 3:7) The electrol...

Embodiment example 3

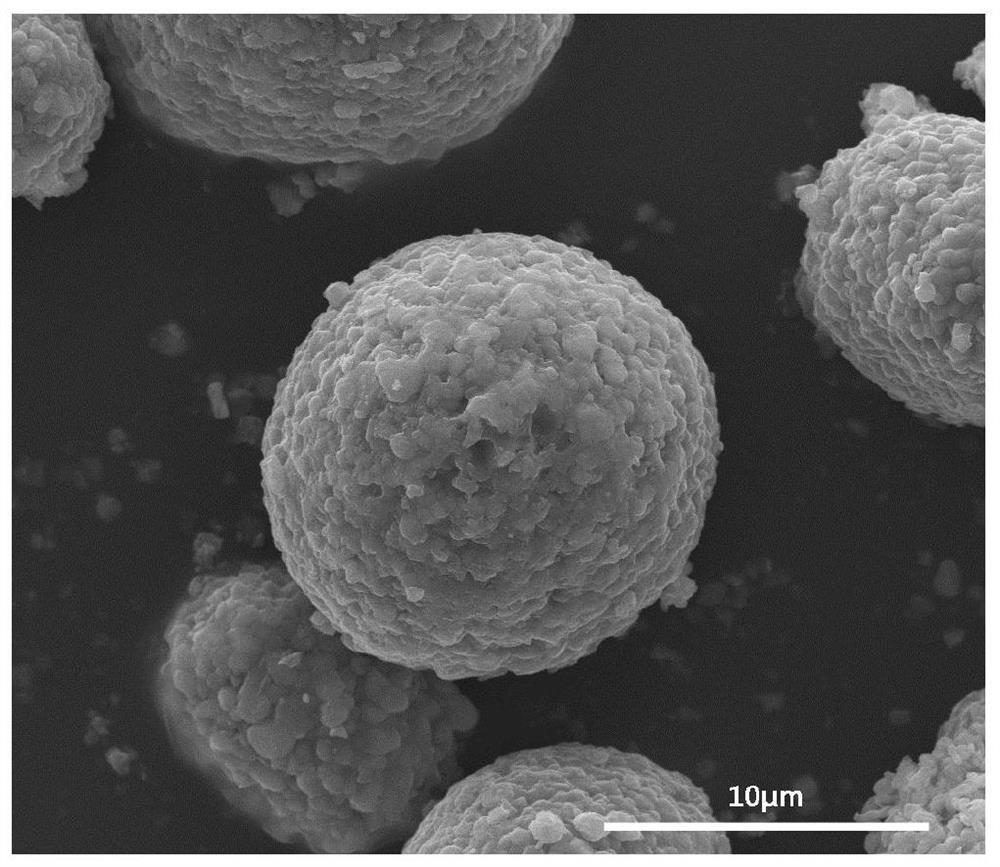

[0036] Accurately weigh 0.15g of acrylonitrile, LiNi 0.6 Co 0.2 Mn 0.2 O 2 5g was dissolved in 25ml of tetrahydrofuran, stirred for 1 hour at 60°C under an argon protective atmosphere, added 0.001g of azobisisobutyronitrile initiator to the mixture, continued to stir at 60°C for 4 hours, and collected by rotary evaporator The organically coated powder was vacuum-dried for 12 h to obtain a sample with a coating amount of 3 wt%.

[0037] Weigh 0.16g of the obtained sample and raw material, respectively mix with 0.02g of conductive carbon black and 0.02g of PVDF, mix in a planetary mixer for 6min, add 500μLNMP, and prepare a slurry with a certain viscosity. Coat the prepared slurry on aluminum foil, dry it in a vacuum oven at 80 °C, and use a punch to make an electrode sheet with a diameter of 12 mm, with 1 mol / L LiPF 6 (The solvent is EC / EMC, and its mass ratio is 3:7) The electrolyte solution as the electrolyte is assembled into a 2016 button battery, and the charge-discha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com