Preparation method of triethanolamine stearate monoester and application of triethanolamine stearate monoester to grinding aiding for talc

A technology of triethanolamine monoester and triethanolamine, which is applied in the field of chemical synthesis agent preparation, can solve the problems of low production capacity, increased production cost of modified talc, unsuitable for continuous production, etc. Sustained development, the effect of eliminating electrostatic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

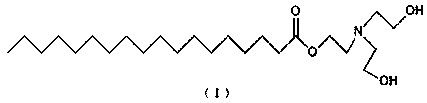

[0020] Preparation of triethanolamine monostearate

[0021] In 500mL there-necked flask, add 142.24g stearic acid (0.5moL), under N 2 Under the atmosphere, heat up to 70°C by heating in an oil bath, stearic acid begins to melt and stir, continue to heat up to 90°C, stearic acid is completely melted, and then start to drop 74.6g triethanolamine (0.5moL) through a constant pressure dropping funnel, The dropwise addition was completed within 30 minutes, and the reaction was continued at 90°C for 3.5 hours. After the reaction was completed, vacuum was applied at 90°C to remove the moisture in the product, and finally the material was poured out while it was hot. Fatty acid triethanolamine monoester.

Embodiment 2

[0023] Preparation of triethanolamine monostearate

[0024] In a 500mL three-necked flask with a magnetic stirrer and a water separator, under an inert gas atmosphere, 74.6g triethanolamine (0.5moL), 142.24g stearic acid (0.5moL) were mixed in a molar ratio of 1moL: 1moL and an organic solvent The toluene phases were mixed, and under magnetic stirring, the reaction was refluxed at 120°C until no water was formed in the water separator (about 12h), and the reaction was closed and cooled to room temperature. Equipped with a distillation device, first evaporate toluene under normal pressure, and then evaporate excess ethanolamine and by-products under reduced pressure to obtain triethanolamine monostearate as a colorless solid to pale yellow solid.

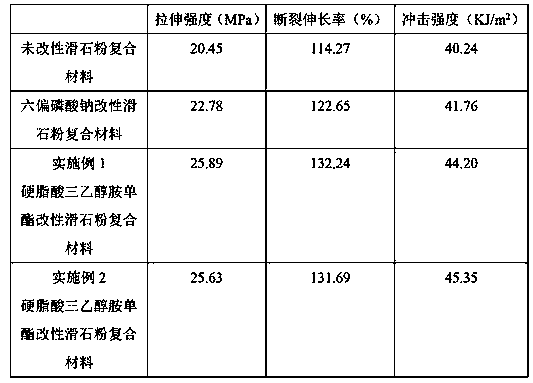

[0025] The triethanolamine stearate monoester in Example 1 and Example 2 was used to prepare a modified talcum powder / polypropylene composite material.

[0026] First, 10 g of triethanolamine stearate was dissolved in ethanol soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com