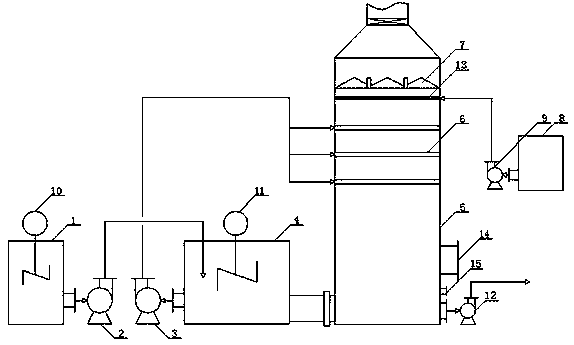

Flue gas desulfurization method and system based on ammonia-magnesium combined reinforced phosphoric ore pulp method

A technology of phosphate rock slurry and flue gas, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of transportation cost constraints, popularization and application, hindering O dissolution, and difficulty in obtaining comprehensive economic benefits. The effect of improving economic benefits, increasing the economic value of by-products, and realizing resource recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Add ammonia water and magnesium oxide to the phosphate rock slurry to form a mixed slurry, control the pH value to be greater than 7; contain SO 2 The flue gas reacts with the sprayed mixed slurry to remove SO in the flue gas 2 After the flue gas is washed by the slurry, it is discharged after demisting; the mixed slurry after the reaction is first passed into oxygen to react, then stirred evenly, and then sent back to the S2 step to continue washing the flue gas, when the magnesium ammonium phosphate in the mixed slurry When the solubility reaches the preset requirement, it is sent to the crystallizer to produce magnesium ammonium phosphate crystals.

Embodiment 2

[0073] Add citric acid after the phosphate rock slurry is milled for 5 minutes, and then continue to grind until the particle size is below 1mm; add ammonia water and magnesium oxide to the phosphate rock slurry to make a mixed slurry, and control the pH value to be greater than 7; contain SO 2 The flue gas reacts with the sprayed mixed slurry to remove SO in the flue gas 2 After the flue gas is washed by the slurry, it is discharged after demisting; the mixed slurry after the reaction is first passed into oxygen to react, then stirred evenly, and then sent back to the S2 step to continue washing the flue gas, when the magnesium ammonium phosphate in the mixed slurry When the solubility reaches the preset requirement, it is sent to the crystallizer to produce magnesium ammonium phosphate crystals.

Embodiment 3

[0075] Add tartaric acid after the phosphate rock slurry is milled for 25 minutes, and then continue to grind until the particle size is less than 1mm; add ammonia water and magnesium oxide to the phosphate rock slurry to make a mixed slurry, and control the pH value to be greater than 7; contain SO 2 The flue gas reacts with the sprayed mixed slurry to remove SO in the flue gas 2 After the flue gas is washed by the slurry, it is discharged after demisting; the mixed slurry after the reaction is first passed into oxygen to react, then stirred evenly, and then sent back to the S2 step to continue washing the flue gas, when the magnesium ammonium phosphate in the mixed slurry When the solubility reaches the preset requirement, it is sent to the crystallizer to produce magnesium ammonium phosphate crystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com