Separation membrane and preparation method and application thereof

A separation membrane and phase separation technology, applied in the field of membrane separation, can solve the problems of exacerbating the consumption of chemical polymer materials and non-renewable petrochemical resources, human health and ecological environment hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

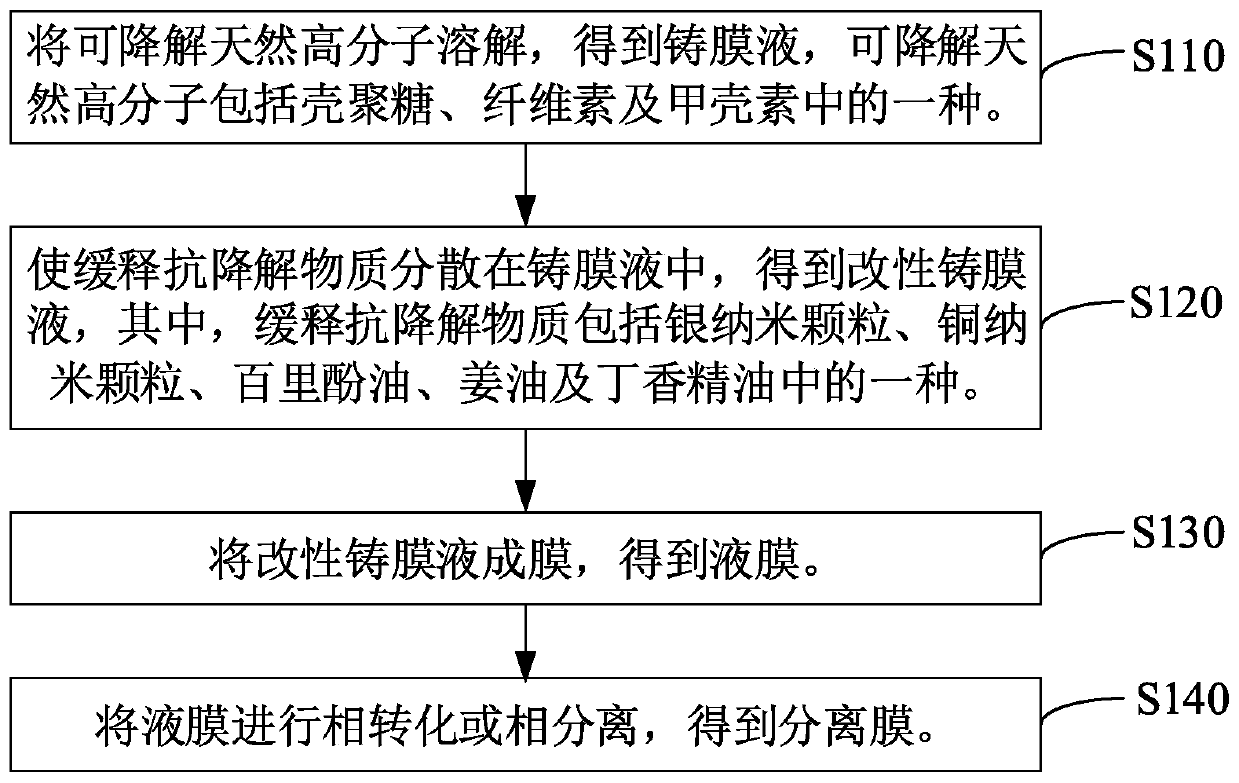

[0036] see figure 1 , the preparation method of the separation membrane of an embodiment, comprises the steps:

[0037] Step S110: Dissolving the degradable natural polymer to obtain a casting solution, the degradable natural polymer includes one of chitosan, cellulose and chitin.

[0038] The sources of the above-mentioned degradable natural polymers are abundant. By selecting different degradable natural polymers, the production cost can be reduced, the structure of the separation membrane can be optimized, the performance of the separation membrane can be improved, and the scope of application of the separation membrane can be expanded.

[0039] In one embodiment, the degradable natural polymer is chitosan. Chitosan is obtained by deacetylation of chitin. Chitin, also known as chitin and chitin, is a natural polysaccharide extracted from the exoskeleton of crustaceans such as shrimps, crabs, insects, and higher fungi. It has a wide range of sources, abundant reserves, ra...

Embodiment 1

[0079] The separation membrane of the present embodiment is a modified chitosan separation membrane containing silver nanoparticles, and the preparation process is as follows:

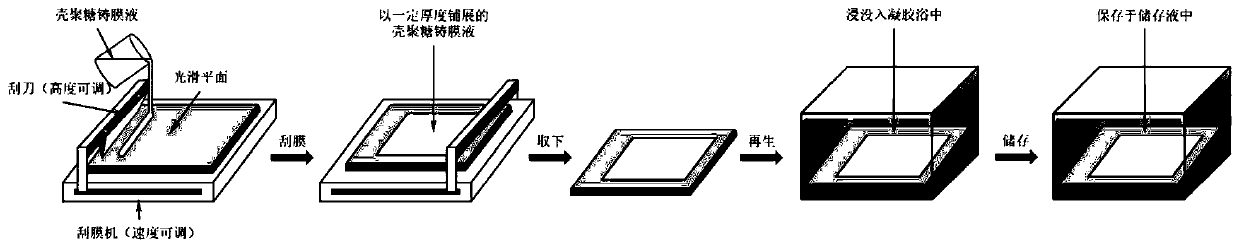

[0080] Lithium hydroxide monohydrate (LiOH·H 2 O), potassium hydroxide and urea were dissolved in ultrapure water, among them, lithium hydroxide monohydrate (LiOH·H 2 O), the mass ratio of potassium hydroxide, urea and water is 8:7:8:77. After being completely dissolved, add 1% silver nanoparticles of the mass of chitosan, and ultrasonically disperse the silver nanoparticles in the solution for 1 h in an ultrasonic pot, then add a certain amount of chitosan powder to make the shell in the casting solution The mass concentration of polysaccharide is 4%, and it is stirred evenly. Then put it into a low-temperature freezer to freeze at -80°C, take it out and stir it with an electric mixer, repeat 3 times until the chitosan powder is evenly dissolved, and then centrifuge at a speed of 11000rpm for 12min ...

Embodiment 2

[0082] The separation membrane of this embodiment is a modified cellulose separation membrane containing thymol oil, and the preparation process is as follows:

[0083] Lithium hydroxide monohydrate (LiOH·H 2 O) and urea were dissolved in ultrapure water, in which lithium hydroxide monohydrate (LiOH·H 2 O), the mass ratio of urea and water is 8: 15: 77. After it is completely dissolved, add thymol oil with a volume mass fraction of 1% of cellulose, and ultrasonically disperse the thymol oil in the solution for 1 hour in an ultrasonic pot, and then add a certain amount of cellulose powder to make the cast film The mass fraction of cellulose in the liquid is 4%, and it is stirred evenly. Then put it into a low-temperature freezer to freeze at -50°C, take it out and stir it with an electric mixer, repeat 3 times until the cellulose powder is evenly dissolved, and then centrifuge at 8000rpm for 15min in a refrigerated centrifuge at -5°C to remove air bubbles , to obtain the mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com