Preparation of nickel-molybdenum-nitrogen co-doped carbon-based catalyst based on sodium chloride template

A carbon-based catalyst, sodium chloride technology, applied in the field of electrocatalysis, can solve the problems of low catalytic activity, low doping efficiency and active site density, etc., and achieves a wide range of raw material sources, a simple and easy-to-operate method, and broad application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

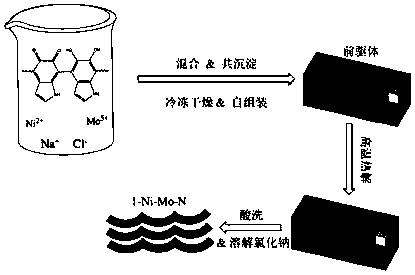

[0020] refer to figure 1 Shown is a schematic diagram of the preparation process of the nickel-molybdenum-nitrogen co-doped carbon-based catalyst of this embodiment.

[0021] (1) Take by weighing 0.237g nickel chloride hexahydrate, 0.273g molybdenum pentachloride and 25g sodium chloride and be dissolved in 50ml deionized water; Under room temperature, stir and dissolve to obtain a mixed solution with a magnetic stirrer at a stirring speed of 500r / min . Then add 0.62g of trishydroxymethylaminomethane, and continue to stir for 0.5h to obtain mixed solution A. Slowly add 100 mg of dopamine hydrochloride to the mixed solution A, and stir for 12 h with a magnetic stirrer at a stirring speed of 300 r / min at room temperature to obtain a mixed solution B. Put the mixed liquid B in the refrigerator for 24 hours to freeze, and then place it in a freeze dryer at -50°C for 60 hours in vacuum to obtain the precursor. Grind the obtained precursor into powder and transfer it to a tube fur...

Embodiment 2

[0024] Weigh 10 g of the 1-Ni-Mo-N-C catalyst synthesized in Example 1 and soak it in 100 ml of 2M hydrochloric acid solution for 8 hours. Then, they were washed with deionized water and ethanol by centrifugation until there was no sodium chloride, and then dried in a vacuum oven at 80°C for 12 hours. Grind the dried powder into fine powder and transfer it to a tube furnace for secondary annealing. The annealing conditions: under an argon atmosphere with a gas flow rate of 50 sccm, the temperature rise range is 30°C-830°C, and the temperature rise rate is 5°C / min, and Maintained at 830°C for 2h. After cooling to room temperature, a nickel-molybdenum-nitrogen co-doped carbon-based catalyst was obtained after secondary annealing, which was denoted as 2-Ni-Mo-N-C.

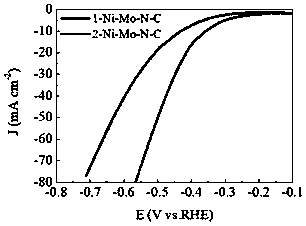

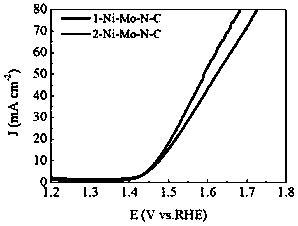

[0025] The 2-Ni-Mo-N-C catalyst prepared in this embodiment 2 adopted a three-electrode system in the electrocatalytic hydrogen evolution and oxygen evolution tests, and the working electrode was a rotating disk elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com