Application of litsea cubeba extract as silage corn anti-mildew additive

A technology of silage corn and extracts, which is applied in the direction of preservation and application of food ingredients containing natural extracts and food ingredients as antimicrobials, and can solve the problems of high user operation level requirements, strong corrosion, and weak applicability , achieve good application prospects, increase protein content, and improve nutritional quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Collect the litsea cubeba fruit that is naturally dried in the shade, crush it into powder, pass it through a 40-mesh sieve, and set it aside. Take 10g of powder and wrap it into a paper bag and place it in a 500mL Erlenmeyer flask, add 250mL of ethyl acetate, soak for 16h, transfer all the contents of the Erlenmeyer flask to a Soxhlet extraction device, set the extraction temperature (105°C) and time (8h), and extract The liquid was filtered, and the solvent was distilled off under reduced pressure to obtain Litsea cubeba extract (Litsea cubeba oil), which was weighed and collected. The extraction rate of litsea cubeba extract is 3.52%. The extracted litsea cubeba extract was analyzed by GC-MS for its main components.

[0019] Gas chromatography conditions: HP-5MS chromatographic column, carrier gas is high-purity helium (99.999%), flow rate 20mL / min, temperature program; injection volume 1μL, start at 50°C, keep for 1min, rise to 260°C at 5°C / min ℃, keep 5min.

[0...

Embodiment 2

[0023] Emulsifier preparation: 20mL Tween 80, 60mL sterile distilled water, 10mL polyethylene glycol and 10mL 95% ethanol, shake well and set aside.

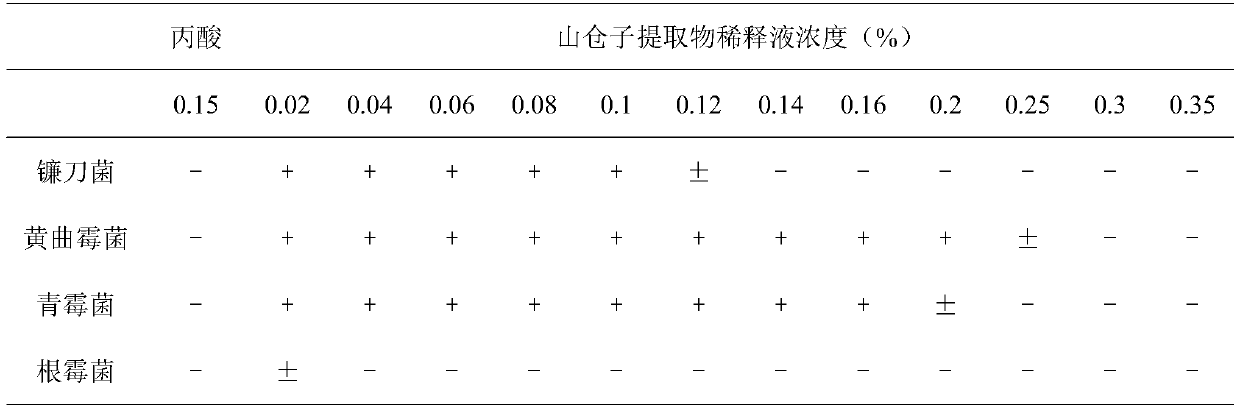

[0024] Preparation of Litsea Cubeba Extract Diluent: Add different volumes of Litsea Cubeba Extract obtained in Example 1 to the emulsifier prepared by the above method to prepare different concentrations of Litsea Cubeba Extract Dilution, Litsea Cubeba Extract The volume fractions of Litsea Cubeba extract in the diluted solution are 0.02%, 0.04%, 0.06%, 0.08%, 0.1%, 0.12%, 0.14%, 0.16%, 0.2%, 0.25%, 0.3%, 0.35%.

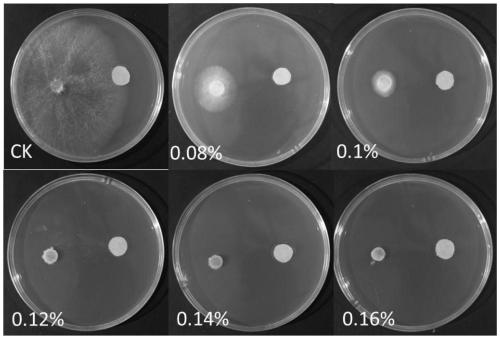

[0025] Four strains of Fusarium, Aspergillus flavus, Penicillium, and Rhizopus were isolated from silage corn, and four purified strains of Fusarium, Aspergillus flavus, Penicillium, and Rhizopus were respectively prepared at a concentration of 10 6 After cfu / mL bacterial suspension and spore suspension, respectively take 1mL on the potato-dextrose agar medium, culture at 25°C for 120h, under sterile conditions, repea...

Embodiment 3

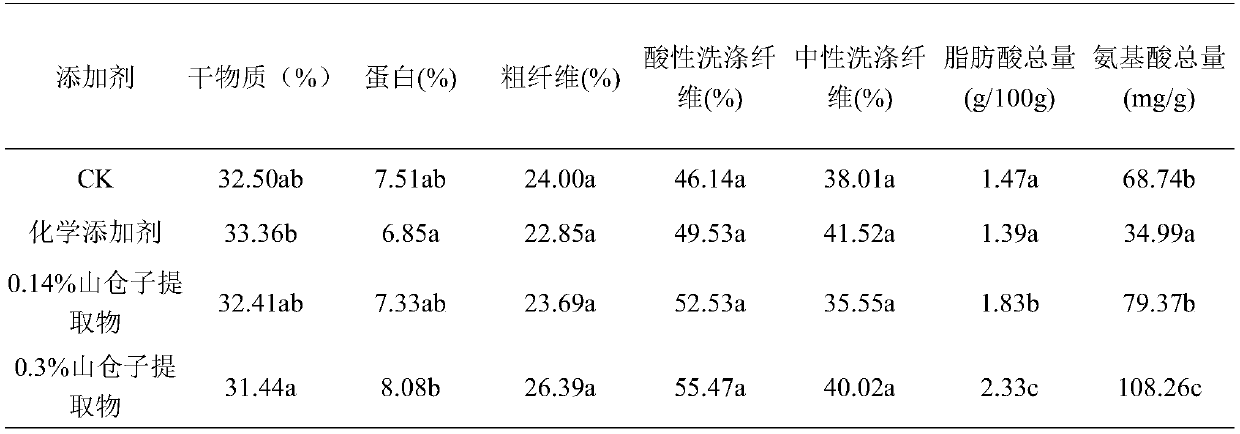

[0031] Get silage corn raw material and be divided into 4 groups, every group 650g, wherein two groups add the Litsea cubeba extract that the embodiment 1 of different volumes obtains respectively, make the volume fraction of Litsea cubeba extract be 0.14% and 0.3% respectively, mix After uniformity, fill them in 1L silage tanks and seal them. The remaining two groups are blank addition (without any medicament) and chemical additives (propionic acid with a volume fraction of 0.15%). , after 45 days of silage fermentation, each treatment was repeated three times, and the dry matter, protein, crude fiber, acid detergent fiber and neutral detergent fiber, amino acids and fatty acids of corn silage were determined. The results are shown in Table 2: for the treatment of adding 0.3% of the extract of Arboria chinensis, the content of protein, fatty acid and amino acid increased by 0.56%, 0.86% and 3.52% respectively compared with the CK group; treatment, the content of protein, fatt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com