Recombinant bacterium for promoting bacillus subtilis to synthesize menadione-7 and gene modification method thereof

A technology of Bacillus subtilis and menadione, applied in the field of biological genetic engineering, can solve the problems of organic solvent residue, low yield, dangerous production environment and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment provides a genetic modification method for promoting the synthesis of menadione-7 by Bacillus subtilis, specifically as follows:

[0023] 1. Materials

[0024] Strains, Plasmids and Media

[0025] See Table 1 for details of all strains and plasmid information involved in the present invention.

[0026] LB medium (peptone 10g / L, yeast extract 5g / L, sodium chloride 10g / L) is used for general cultivation of B. subtilis, solid medium is added with 15g / L agar powder, neomycin 16μg / mL when needed , or chloramphenicol 8 μg / mL. Fermentation medium: glycerol 30mL / L, soybean peptone 60g / L, yeast extract 5g / L, K 2 HPO 4 3g / L, MgSO 4 ·7H 2 O 0.5g / L, pH7.3.

[0027] The strains and plasmids involved in the experiments in Table 1

[0028]

[0029]

[0030] Reagents and instruments

[0031] FastTaq enzyme, Hifi DNA polymerase, and dNTP were all purchased from Beijing Quanshijin Biotechnology Co., Ltd.; the standard product MK-7 was purchased from Chroma...

Embodiment 2

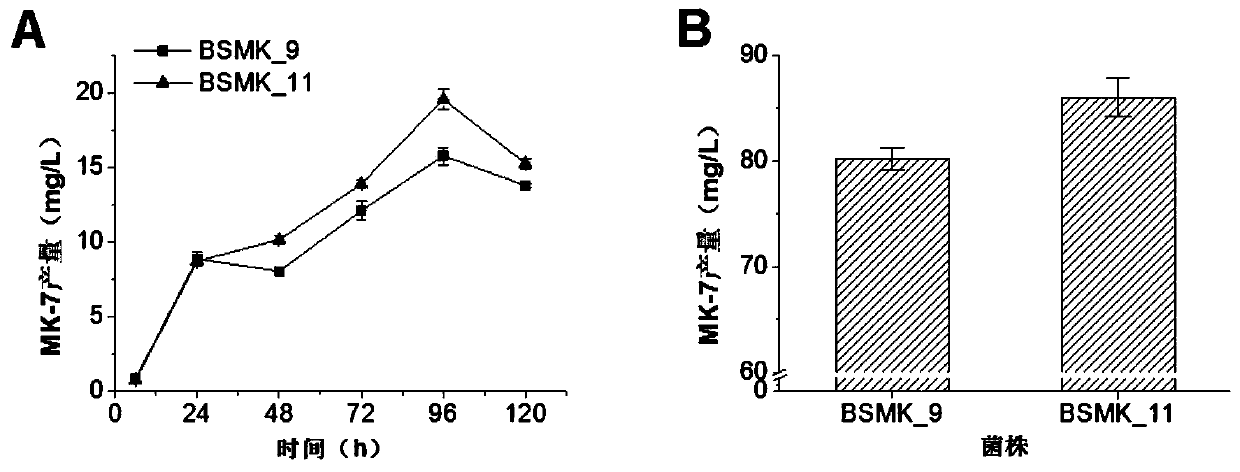

[0044] The cultivation of embodiment 2 recombinant bacterial strain BSMK_11

[0045] Shake flask fermentation culture and determination of cell growth, fermentation medium and fermentation conditions are shown in Table 3.

[0046] Table 3 fermentation medium and fermentation conditions

[0047] parameter scope glycerin 20~80mL / L soy peptone 60~180g / L Yeast extract 0~20g / L K 2 HPO 4

1~5g / L MgSO 4 ·7H 2 o

0.1~0.8g / L pH 6.5~7.5 Inoculation amount 1%~6% temperature 35~45℃ Rotating speed 100~250r / min fermentation time 72-144h

[0048] 500mL shake flask fermentation: Pick a single colony on a newly activated plate and insert it into a 250mL shake flask filled with 30mL LB medium, shake and culture at 200r / min, 37°C for 14h; In the 500mL Erlenmeyer flask (three parallel), 37 ℃, dark conditions, 220r / min shaking culture for 120h.

[0049] Biomass measurement: take samples after 6 hours of f...

Embodiment 3

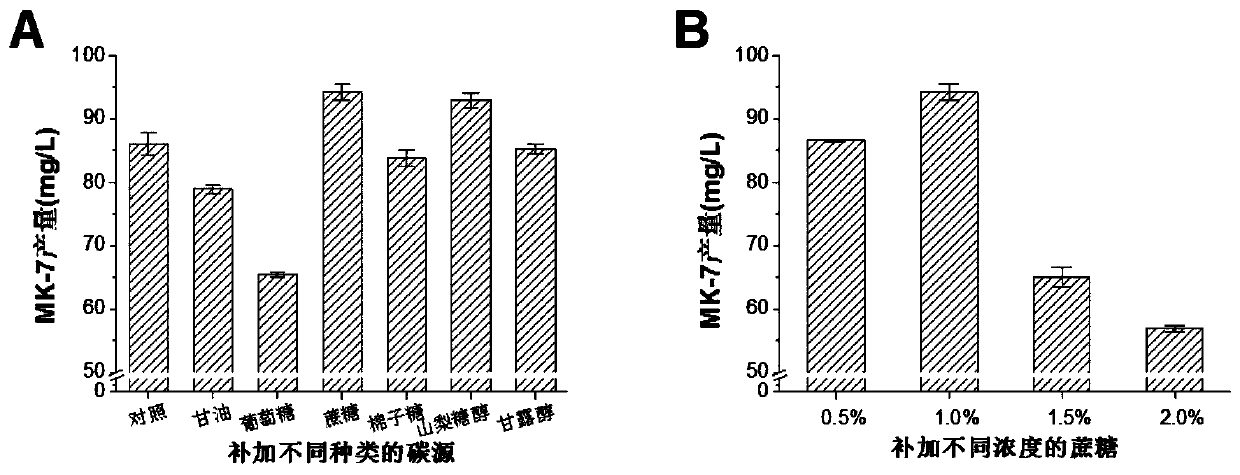

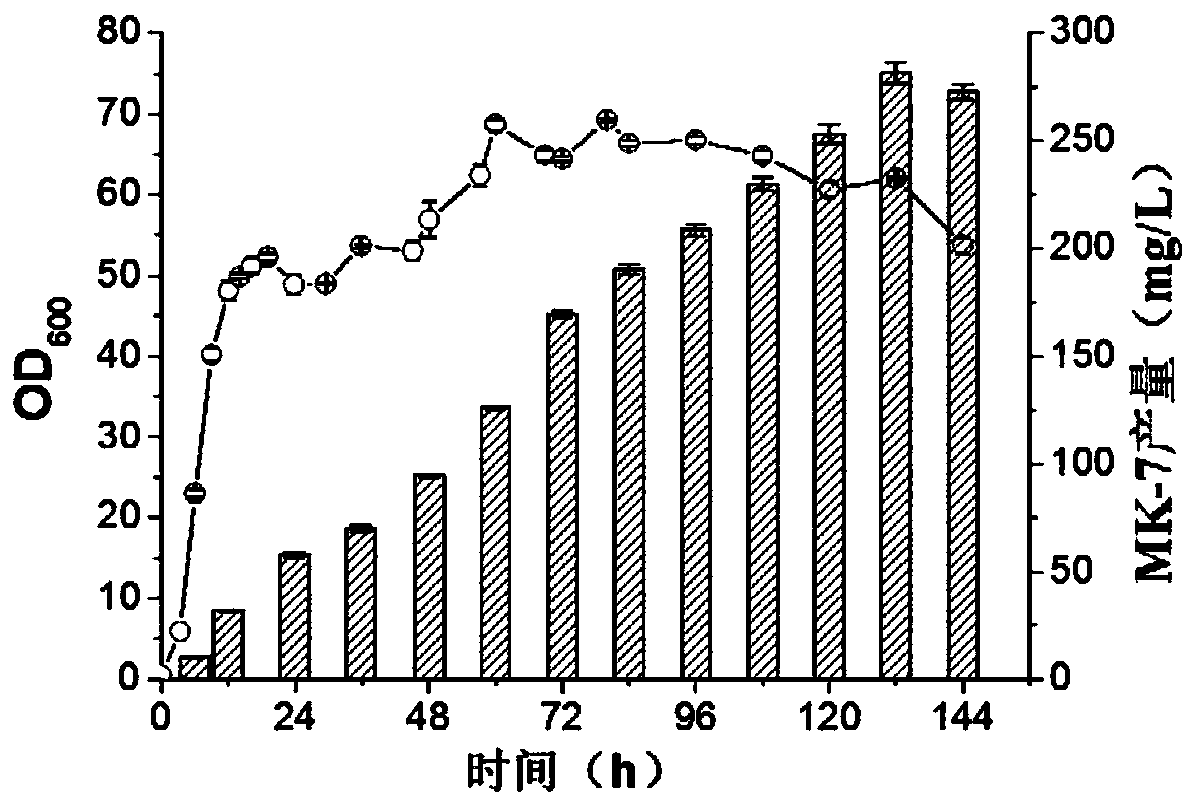

[0060] Embodiment 3 carbon source optimization

[0061] It can be seen from Table 4 that the growth of the starting bacterium BSMK_9 decreased at 48 hours of fermentation, and then decreased, that is, secondary growth phenomenon appeared, indicating that the carbon source glycerol was exhausted at this time, and then soybean peptone provided nitrogen source and nitrogen source. Carbon source to meet the growth requirements of Bacillus subtilis. In order to further increase the yield of MK-7, the present invention adds 1.0% glycerol, glucose, sucrose, raffinose, sorbitol and mannitol to the fermentation medium respectively. As can be seen from Table 6, the addition of glycerol causes the MK-7 yield to decrease by 8.3% compared with the initial condition, indicating that the presence of 3.0% glycerol in the fermentation medium is most conducive to the synthesis of MK-7; in addition, the addition of glucose, raffinose or mannitol Both also resulted in a decrease in the yield of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com