Polyarylether ultrafiltration membrane, nanofiltration membrane and method for preparation and reversible conversion of ultrafiltration and nanofiltration

A nanofiltration membrane and polyarylene ether technology, which is applied in the field of polyarylene ether ultrafiltration membranes containing tertiary amine structure, can solve the problem of hydrophobicity, poor organic solvent corrosion resistance, hydrophobicity, solvent corrosion resistance, poor temperature resistance, and organic solvent resistance. Corrosion is not ideal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Preparation of tertiary amine-containing polyarylether resin

[0058] Sodium hydrosulfide 117.1g (equivalent to pure sodium hydrosulfide 56g), N,N'-bis(p-fluorobenzoyl-3-aminopropyl)methanamine 19.45g, 4,4'-dichlorodiphenyl sulfone 272.7g, lithium hydroxide 10g, potassium glycocholate 2g, N-methylpyrrolidone 1500ml, put into the reaction kettle, under the protection of nitrogen, dehydration reaction at 185°C for 2h, then keep at 200°C for 6h, the above polymerization Cool the temperature of the polymer solution to 60°C, pour it into water while stirring, and obtain the crude polymer product in the form of strands;

[0059] (2) Purification of tertiary amine-containing polyarylether resin

[0060] Crushing the crude product of tertiary amine polyarylether resin obtained in step (1), washing the crushed crude product with water and ethanol three times, filtering, recycling the filtrate, and drying the collected filter cake at a temperature of 120°C for 8 hours , to ...

Embodiment 2

[0070] (1) Preparation of tertiary amine-containing polyarylether resin

[0071] Sodium sulfide 168.8g (equivalent to pure sodium sulfide 78g), N,N'-bis(p-fluorobenzoyl-3-aminopropyl)methanamine 29.2g, 4,4'-difluorobenzophenone 201.7 g, sodium carbonate 1g, zinc alginate 20g, N-cyclohexylpyrrolidone 1000ml, add to the reaction kettle, under the protection of nitrogen, dehydrate at 195°C for 1h, then keep at 210°C for 8h, cool down the above polymer solution to 70°C, and poured into water while stirring to obtain the crude product of linear polymer;

[0072] (2) Purification of tertiary amine-containing polyarylether resin

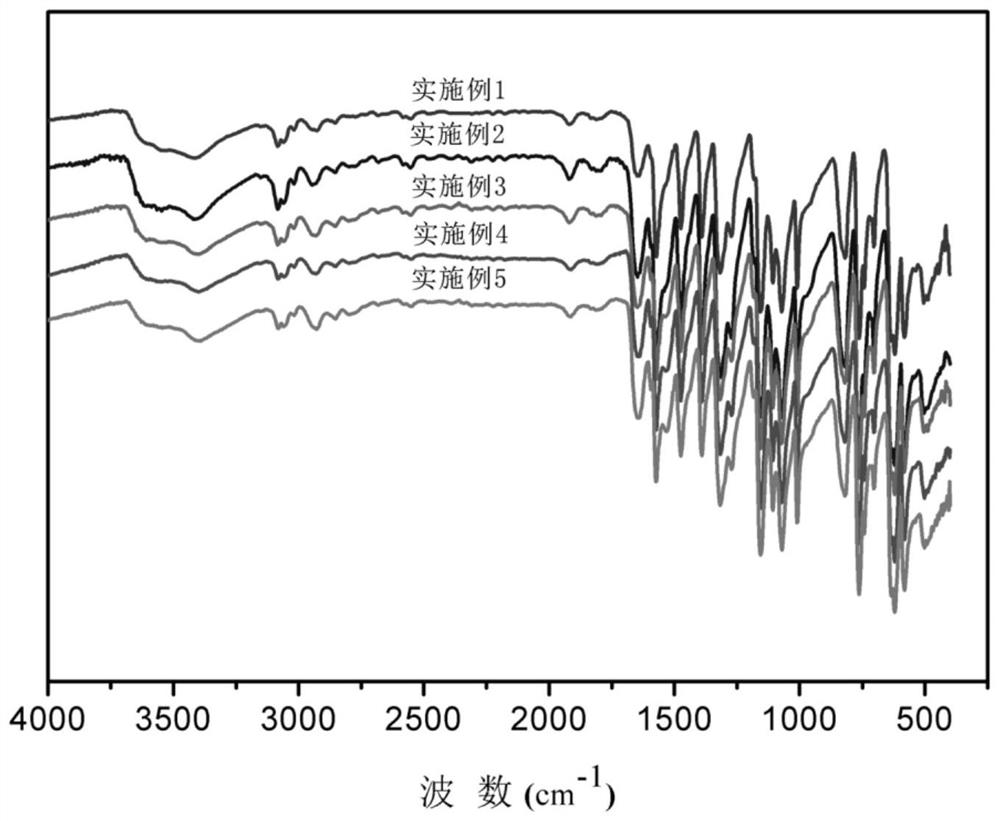

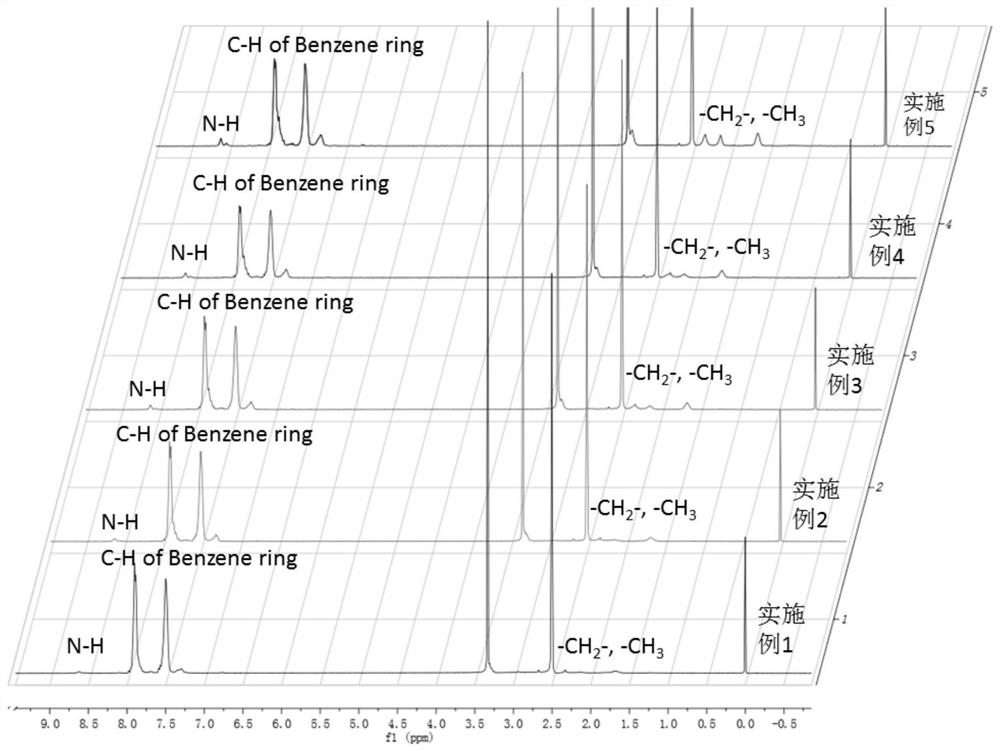

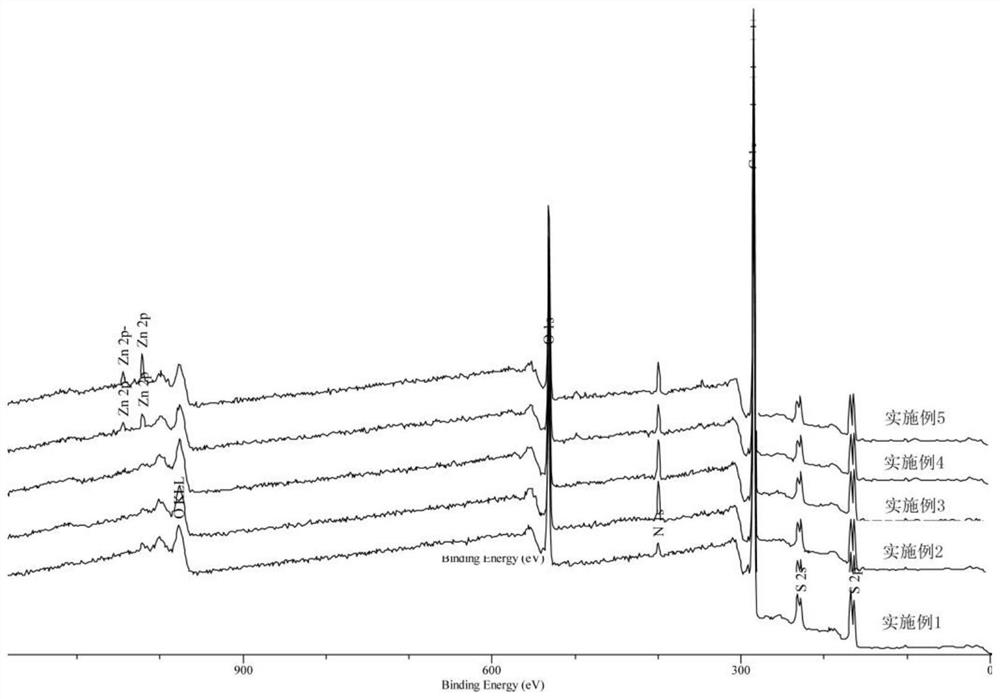

[0073] Crushing the crude product of tertiary amine polyarylether resin obtained in step (1), washing the crushed crude product with water and ethanol four times, filtering, recycling the filtrate, and drying the collected filter cake at a temperature of 110°C for 10 hours , to obtain purified tertiary amine-containing polyarylether resin, its IR and NMR ...

Embodiment 3

[0083] (1) Preparation of tertiary amine-containing polyarylether resin

[0084] 250g of 4,4'-dimercaptodiphenylsulfide, 38.9g of N,N'-bis(p-fluorobenzoyl-3-aminopropyl)methanamine, N,N'-bis(p-fluorobenzene Formyl) m-phenylenediamine 316.8g, barium hydroxide 30g, zinc oxalate 30g, isoquinoline 3000ml, add to the reaction kettle, under the protection of nitrogen, dehydration reaction at a temperature of 190 ° C for 1.5 h, and then at a temperature of 220 ° C Keep for 6 hours, cool down the above polymer solution to 90°C, pour it into water while stirring, and obtain the crude polymer product in the form of strands;

[0085] (2) Purification of tertiary amine-containing polyarylether resin

[0086] Crushing the crude product of tertiary amine polyarylether resin obtained in step (1), washing the crushed crude product with water and ethanol for 5 times, filtering, recycling the filtrate, and drying the collected filter cake at a temperature of 100°C for 24 hours , to obtain pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com