Hierarchical structure glass fiber and lithium metal compound and preparation method thereof

A glass fiber and hierarchical structure technology, applied to structural parts, active material electrodes, electrical components, etc., can solve the problems of thermal runaway, explosion, and easy formation of non-uniform deposition in the battery system, and achieve cycle performance guarantee and high battery safety , the overall thickness controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

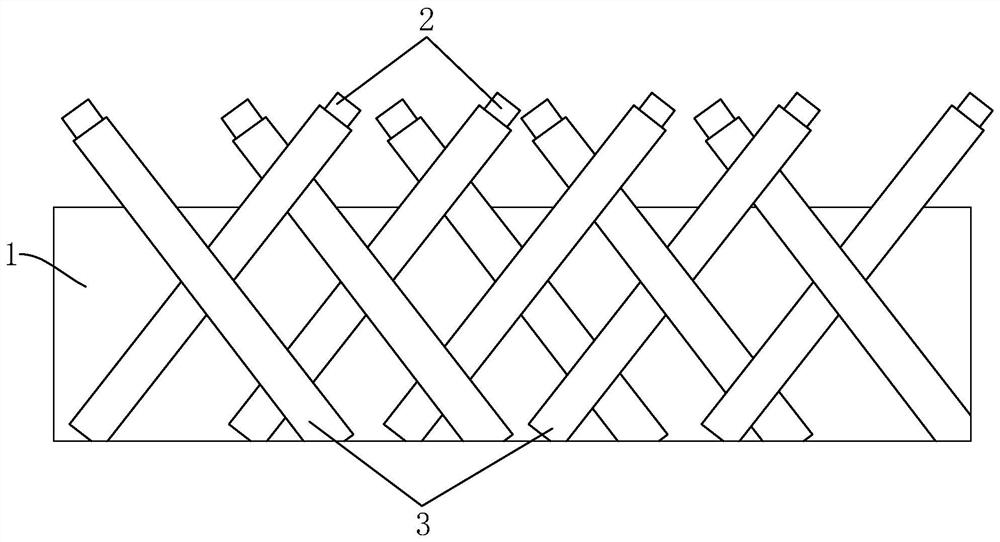

[0046] refer to figure 1 , a composite of glass fiber and metal lithium with a hierarchical structure, comprising a lithium layer 1 and a glass fiber layer 2, the lower part of the glass fiber layer 2 is inserted into the lithium layer 1, and the upper part of the glass fiber layer 2 is exposed above the lithium layer 1. The glass fiber layer 2, except the top surface, is coated with a conductive layer 3, which is lithiophilic and electronically conductive, while the conductivity of the glass fiber is less than 10 -8 S / cm, so that the exposed tip of the glass fiber layer 2 has no electronic or ionic conductivity. Among them, the glass fiber layer 2 is made of glass fiber braid.

[0047] The thickness of the glass fiber layer 2 inserted into the lithium layer 1 is the same as the thickness of the lithium layer 1, and the thickness of the lithium layer 1 is (positive electrode surface capacity*(1-Coulomb efficiency)*5*expected number of cycles+(0 to 10)) μm, so that the lithiu...

Embodiment 2

[0055] The difference from Example 1 is that the preparation method of the composite of graded structure glass fiber and metallic lithium includes the following steps:

[0056] S1, mask the upper surface of the glass fiber layer 2 with adhesive tape, spray the glass fiber with an aqueous solution of poly(3,4-ethylenedioxythiophene), combine with the unmasked surface of the glass fiber, and adhere to the glass fiber after drying. A conductive layer 3 is formed on the surface of the glass fiber, and then the tape is torn off;

[0057] S2, melting lithium metal at 300°C, inserting graded glass fibers into the molten lithium metal, and cooling at room temperature to form;

[0058] S3, the above-mentioned composite is put into a sealed bag for isostatic pressing operation, and the metal lithium is continuously pressed into the graded glass fiber;

[0059] S4, a composite of graded structure glass fiber and metallic lithium is obtained.

[0060] In the embodiment, the total thickn...

Embodiment 3

[0062] The difference from Example 1 is that the preparation method of the composite of graded structure glass fiber and metallic lithium includes the following steps:

[0063] S1, the upper surface of the glass fiber layer 2 is masked with adhesive tape, and the glass fiber is soaked with a solution of palladium chloride and tin dichloride, and the palladium metal obtained by the reaction will be combined with the unmasked surface of the glass fiber, and dried. After attaching to the surface of the glass fiber to form a conductive layer;

[0064] S2, the above-mentioned composite is connected to cathode electroplating, and gold electroplating can be performed on the glass fiber surface to form conductive layer 3;

[0065] S2, melting lithium metal at 300°C, inserting graded glass fibers into the molten lithium metal, and cooling at room temperature to form;

[0066] S3, the above-mentioned composite is put into a sealed bag for isostatic pressing operation, and the metal lit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com