Lithium ion secondary battery pole piece and lithium ion secondary battery

A secondary battery, lithium ion technology, used in secondary batteries, secondary battery repair/maintenance, battery electrodes, etc. Safety issues and other issues, to achieve the effect of improving battery kinetic performance and cycle performance, good electrolyte absorption ability, and improving ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

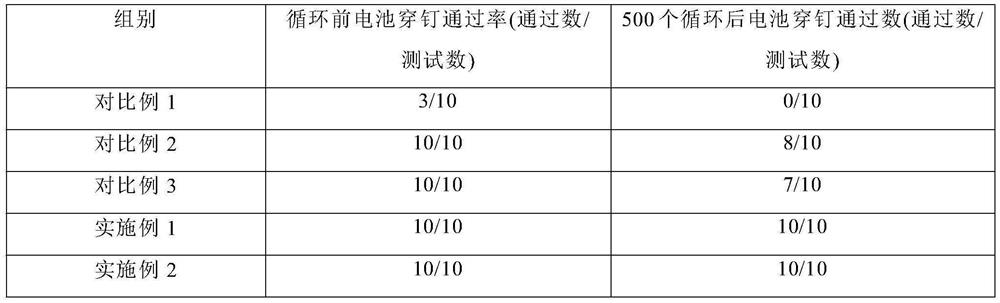

Examples

preparation example Construction

[0038] (1) Preparation of porous insulating coating: dissolve the first binder in the first solvent to form a polymer solution, add dopamine-coated inorganic particles and mix uniformly, and evenly coat the prepared mixture on the active material on the surface of the layer, and then dried to obtain a porous insulating coating. The first solvent that can be used is not particularly limited, as long as it can dissolve the first binder and uniformly disperse the inorganic particles and can be easily removed during coating and drying, the first solvent includes but not limited to tetrahydrofuran, methyl ethyl ketone, dimethyl formamide , Dimethylacetamide, Tetramethylurea, Tetramethylphosphate, Acetone, Dichloromethane, Chloroform, Dimethylamide, N-Methylpyrrolidone (NMP), Cyclohexane, Water and mixtures thereof. The concentration of the first binder is 1-99wt%, preferably 30-60wt%. In order to coat the mixture of the dopamine-coated inorganic particles and the binder on the sur...

Embodiment 1

[0041] (1) Preparation of positive electrode sheet: Lithium cobalt oxide, conductive carbon, and binder polyvinylidene fluoride are mixed uniformly in N-methylpyrrolidone (NMP) solvent at a mass ratio of 96:2.0:2.0 to make positive electrode slurry, Then it is coated on aluminum foil and dried at 110°C to obtain a positive electrode sheet, which is then cold pressed and ready for use.

[0042] Preparation of porous insulating coating: add 13wt% polyacrylate emulsion (40% content in aqueous solution) to deionized water and stir for 1h, then add 85wt% dopamine-coated Al 2 o 3 After the particles were stirred for 2 hours, they were ground in a ball mill for 1 hour, and 2 wt% sodium carboxymethylcellulose (CMC) was added to the ground slurry, and the mixture was stirred for 1 hour to prepare a slurry. Then use the gravure coating to uniformly cover the above-mentioned slurry on both surfaces of the above-mentioned cold-pressed positive electrode, the coating thickness on both sid...

Embodiment 2

[0048](1) Preparation of positive electrode sheet: Lithium cobalt oxide, conductive carbon, and binder polyvinylidene fluoride are mixed uniformly in N-methylpyrrolidone (NMP) solvent at a mass ratio of 96:2.0:2.0 to make positive electrode slurry, Then it is coated on aluminum foil and dried at 110°C, then cold-pressed, stripped, trimmed, and lug-welded to make a positive electrode sheet.

[0049] (2) Preparation of negative electrode sheet: mix graphite, conductive carbon, thickener sodium carboxymethyl cellulose, and binder styrene-butadiene rubber in deionized water at a mass ratio of 95:2.0:1.0:2.0 to make negative electrode slurry material, and then coated on copper foil and dried at 85°C and then cold pressed for later use.

[0050] Preparation of porous insulating coating: add 13wt% polyacrylate emulsion (40% content in aqueous solution) to deionized water and stir for 1h, then add 85wt% dopamine-coated Al 2 o 3 After the particles were stirred for 2 hours, they were...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com