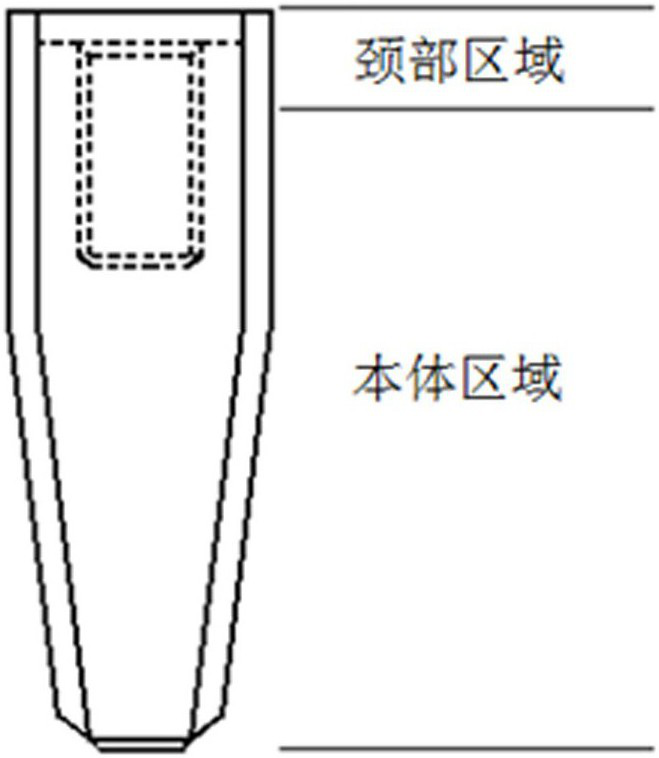

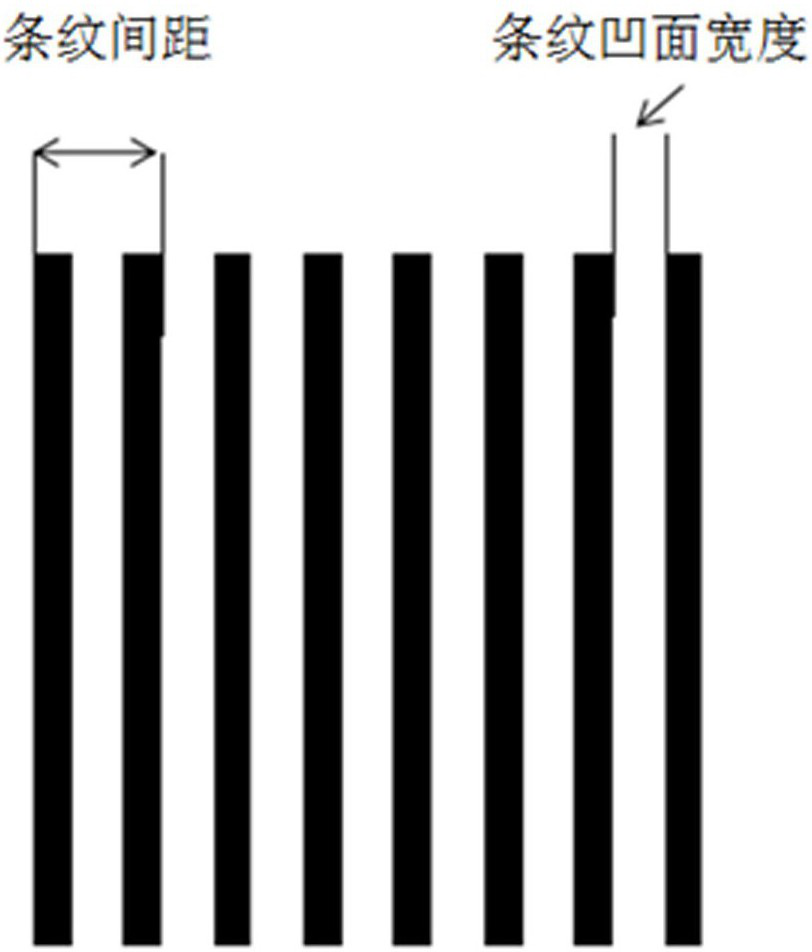

A kind of dental implant and dental implant and preparation method thereof

An implant and dental technology, used in dentistry, implants, prostheses, etc., to achieve the effect of favorable adhesion and proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Place the pure titanium implant matrix in a cleaning tank containing a surfactant (specifically PWC-401 cleaning agent, the same below), perform ultrasonic degreasing and cleaning at 60-70°C for 10 minutes, and rinse with purified water Drying, then pickling treatment at room temperature for 15 seconds in an acidic mixed solution containing 12% nitric acid and 5% hydrofluoric acid by volume fraction, rinsed with purified water, and dried for use;

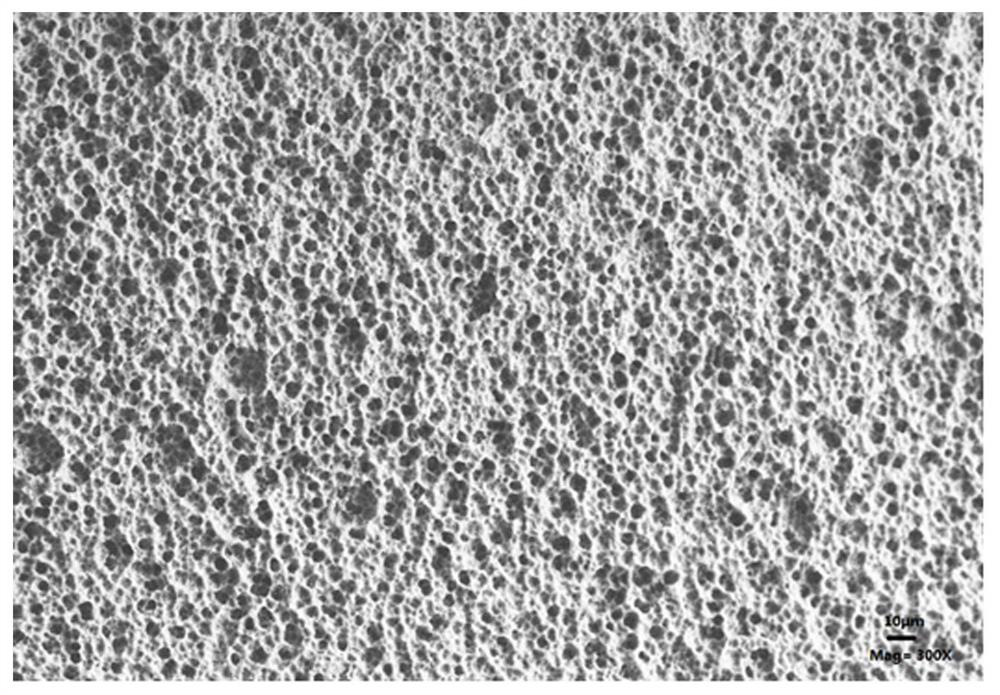

[0043] (2) Put the clean implant matrix in a sandblasting machine, and use 80 μm and 180 μm ceramic sand at a mass ratio of 1:1 for sandblasting treatment under the condition of a pressure of 5 bar and a distance of 0.5 cm. After sanding, the implants were ultrasonically cleaned in acetone, ethanol, and deionized water for 10 minutes, and then placed in a solution containing 15wt% sulfuric acid, 8wt% hydrochloric acid, 1wt% nitric acid, 0.2wt% ethylene glycol, and 0.02g / L perfluorooctanesulfonic acid. Perform high-tempera...

Embodiment 2

[0049] (1) Place the pure titanium implant matrix in a cleaning tank containing surfactant, ultrasonically degrease and clean it at 60-70°C for 10 minutes, rinse with purified water and then dry it. and 5% hydrofluoric acid in an acidic mixed solution at room temperature for 15 seconds, rinsed with purified water, and then dried for use;

[0050] (2) Put the clean implant matrix in the prepared micro-arc oxidation treatment solution (1L of micro-arc oxidation treatment solution contains 6g of calcium formate, 6mL of sulfuric acid, 4mL of hydrochloric acid and 6g of polypropyleneimine with a number average molecular weight of 4000) Among them, the implant matrix is used as the anode, and the stainless steel is used as the cathode, and the DC pulse micro-arc oxidation bioceramic equipment is used for micro-arc oxidation treatment. The process parameters of the micro-arc oxidation are set as: constant voltage mode, and the working voltage adjustment range is forward voltage 150 ...

Embodiment 3

[0055] (1) Place the pure titanium implant matrix in a cleaning tank containing surfactant, ultrasonically degrease and clean it at 60-70°C for 10 minutes, rinse with purified water and then dry it. and 5% hydrofluoric acid in an acidic mixed solution at room temperature for 20 seconds, rinsed with purified water, and then dried for use;

[0056] (2) Put the clean implant matrix in the prepared micro-arc oxidation treatment solution (1L micro-arc oxidation treatment solution contains 8g calcium acetate, 3mL sulfuric acid, 4mL nitric acid and 9g sodium ethylenediene triamine pentaacetate), With the implant matrix as the anode and stainless steel as the cathode, the micro-arc oxidation treatment is carried out with the DC pulse micro-arc oxidation bioceramic equipment. The process parameters of the micro-arc oxidation are set as: constant voltage mode, and the working voltage adjustment range is forward voltage 150~300V , Negative voltage 0V, pulse frequency 100Hz, duty cycle 5%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com