Preparation method of lithium ion battery negative electrode and application thereof in lithium ion battery

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, batteries, secondary batteries, etc., can solve the problems of difficult control of sulfide structure, unfavorable industrial production, long reaction time, etc., to achieve the benefit of electron transmission, Avoid the use of conductive agents and binders, the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

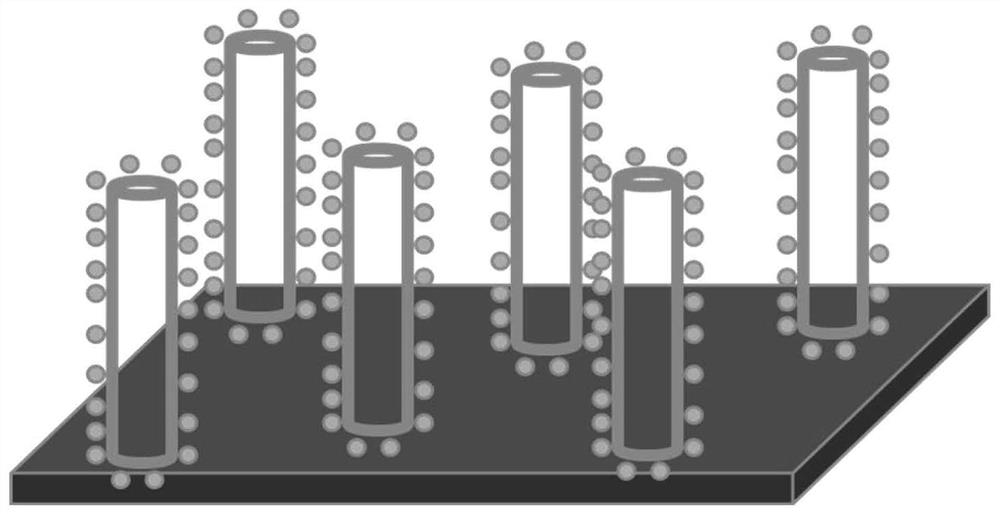

[0019] (1) Prepare silica nanorods first: dissolve CTAB, sodium citrate, and TEOS with a mass ratio of 1:1:1.5 in a mixture of organic solvent propanol and water, then add ammonia water, stir, and add to a hydrothermal kettle , then add carbon cloth as a substrate, and react at 220 degrees Celsius for 3 hours to obtain carbon cloth loaded with silica nanorods;

[0020] (2) Dissolve 0.4 mol of thiourea, 0.2 mol of cobalt chloride, and 0.1 mol of nickel chloride in deionized water successively, and mix ultrasonically to obtain an electrochemical deposition precursor solution, and then add the carbon cloth of step (1) to Among them, at 0.5mA / cm 2 Deposit under constant current conditions for 15 minutes, and grow nickel-cobalt sulfide on the surface of silicon dioxide. After the deposition, the electrode material is alternately washed with deionized water and ethanol for several times, and dried to obtain cobalt-cobalt sulfide-loaded nickel-SiO 2 Carbon cloth of composite materia...

Embodiment 2

[0024] (1) Prepare silica nanorods first: dissolve CTAB, sodium citrate, and TEOS with a mass ratio of 1:1.02:1.5 in a mixture of organic solvent propanol and water, then add ammonia water, stir, and add to a hydrothermal kettle , then add carbon cloth as a substrate, and react at 200 degrees Celsius for 3 hours to obtain carbon cloth loaded with silica nanorods;

[0025] (2) Dissolve 0.4 mol of thiourea, 0.2 mol of cobalt chloride, and 0.1 mol of nickel chloride in deionized water successively, and mix ultrasonically to obtain an electrochemical deposition precursor solution, and then add the carbon cloth of step (1) to Among them, by electrochemical deposition method, at 1mA / cm 2 Deposit under constant current conditions for 15 minutes, and grow nickel-cobalt sulfide on the surface of silicon dioxide. After the deposition, the electrode material is alternately washed with deionized water and ethanol for several times, and dried to obtain cobalt-cobalt sulfide-loaded nickel-S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com