Graphene oxide-cerium oxide-iron oxide composite material and synthetic method thereof, and application in catalytic degradation

A technology of composite materials and synthesis methods, which is applied in the field of catalyst synthesis and can solve problems such as low catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

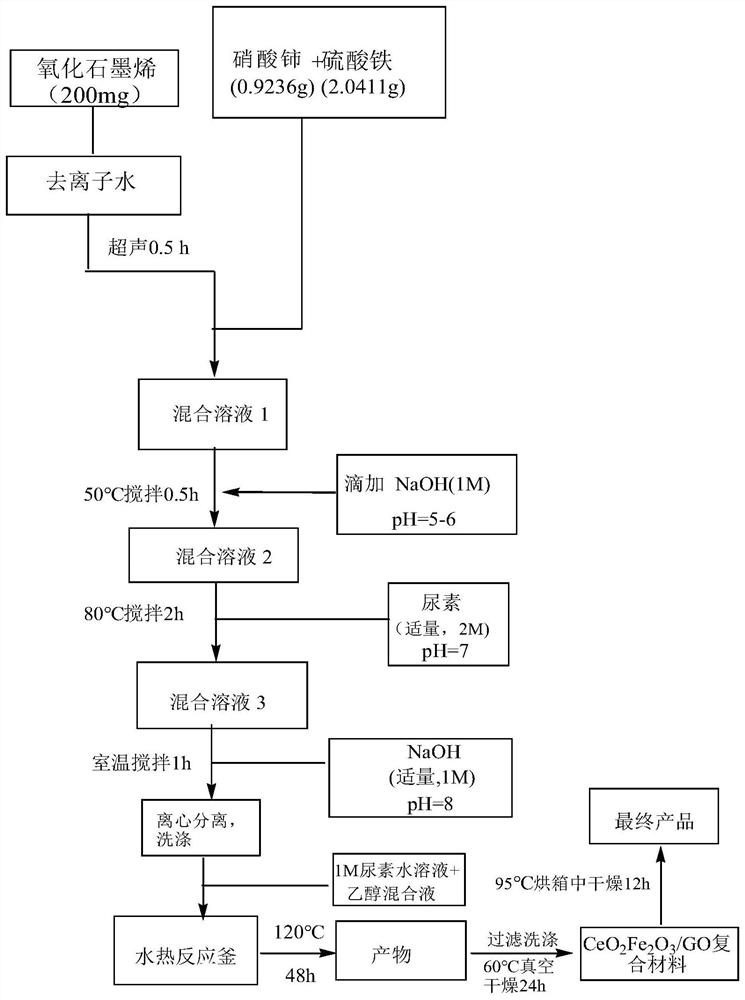

Method used

Image

Examples

Embodiment Construction

[0066] 1. Experimental part

[0067] 1. Main raw materials and instruments

[0068] The test material provided by the implementation of the present invention is: graphene oxide (GO) (AA, Suzhou Carbon Abundance Technology Co., Ltd.), cerium oxide (CeO 2 ) (AR, Sinopharm Chemical Reagent Co., Ltd.), sodium hydroxide (NaOH) (AR, Guangdong. Shantou Xilong Chemical Factory), hydrochloric acid (HCl) (AR, Xilong Science Co., Ltd.), nitric acid (HNO 3 ) (AR, Xilong Science Co., Ltd.), ethanol (C 2 h 5 OH) (AR, Xilong Science Co., Ltd.), hydrogen peroxide (H 2 o 2 ) (AR, Xilong Science Co., Ltd.), iron sulfate (Fe 2 (SO 4 ) 3 ) (AR, Xilong Science Co., Ltd.), urea (H 2 NCONH 2 ) (AR, Xilong Science Co., Ltd.), Methanol (CH 3 OH) (AR, Xilong Science Co., Ltd.), potassium hydrogen persulfate (KHSO 5 ) (AR, Shanghai Aladdin Biochemical Technology Co., Ltd.), malachite green (C 23 h 25 ClN 2 ) (AR, Xilong Scientific Co., Ltd.).

[0069] The instrument provided by the implem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com