Hazardous waste incineration denitration catalyst and preparation method thereof

A denitration catalyst, hazardous waste technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem that the mechanical strength of the catalyst is difficult to support the catalytic work, the influence of the mechanical strength of the catalyst, and the reduction of the catalytic efficiency of the catalyst, etc. problem, to achieve good application prospects, good mechanical properties, and the effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Configure titanate coupling agent solution:

[0027] Mix titanate coupling agent TC-F of Tianchen Chemical and acetone at a volume ratio of 1:10 and stir evenly to obtain a titanate coupling agent.

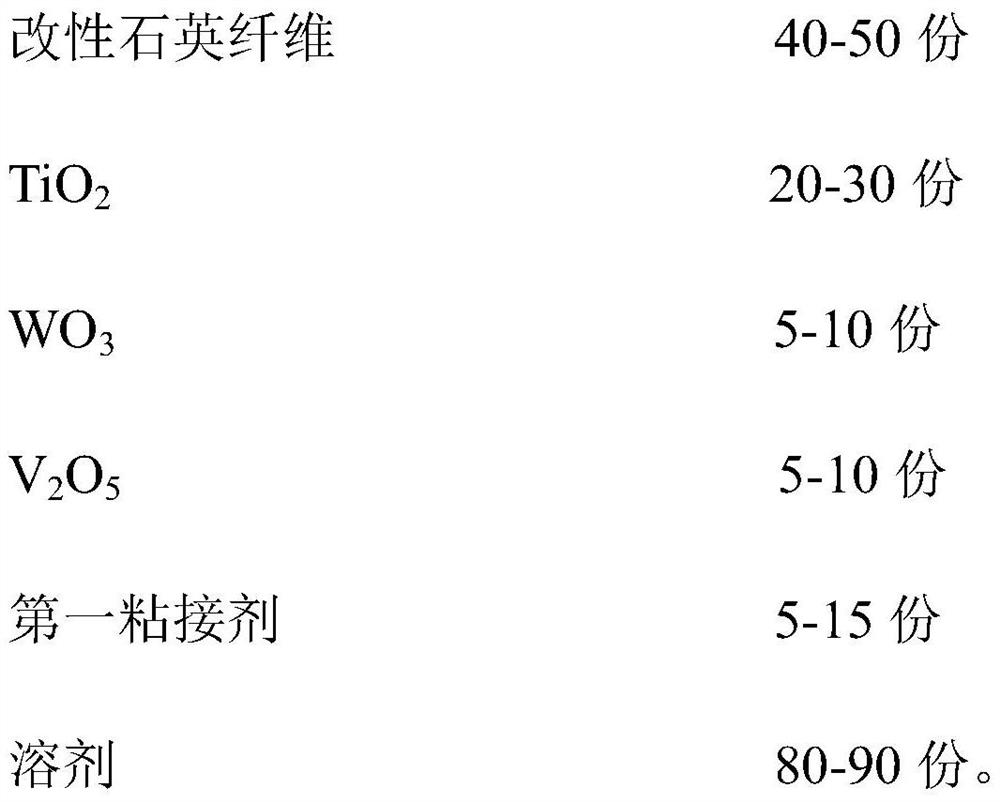

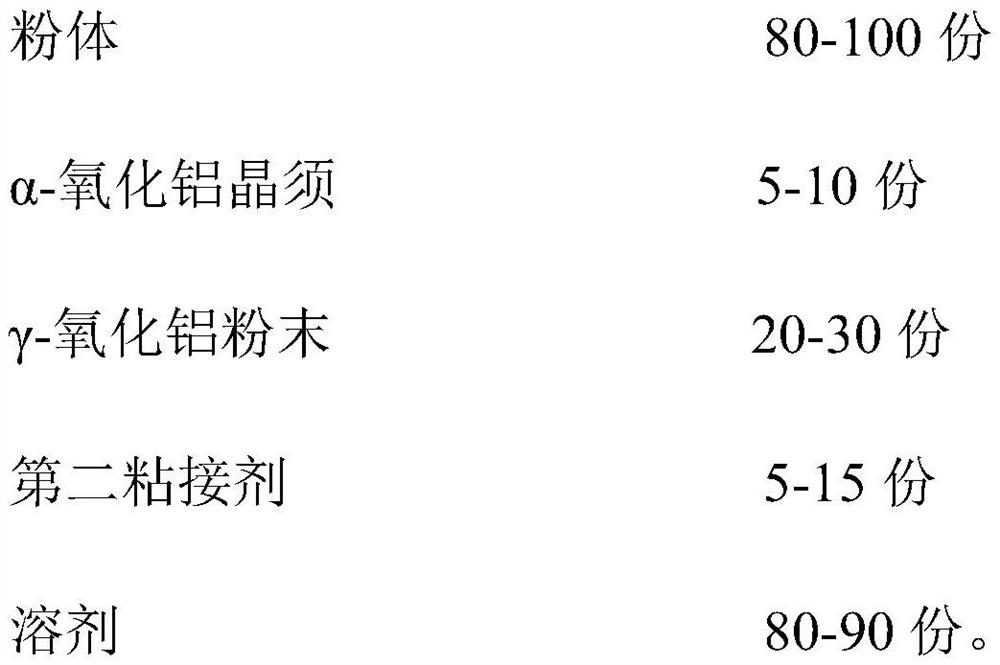

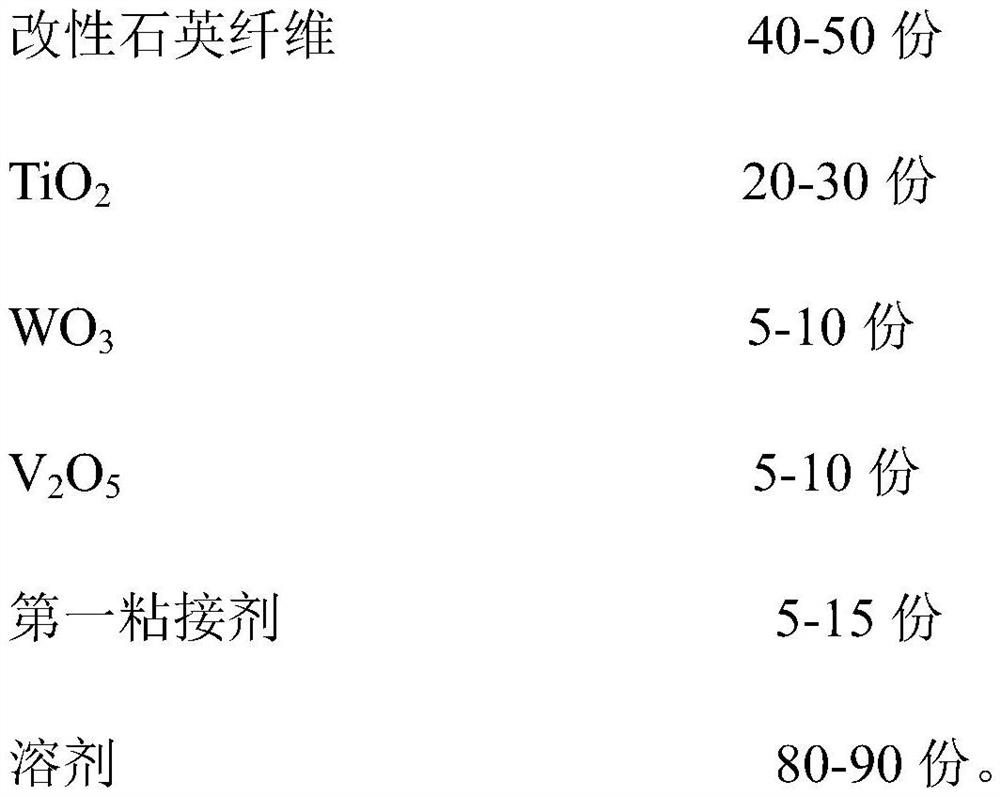

[0028] Immerse 100 parts of quartz fiber in 55 parts of titanate coupling agent, after immersion treatment for 1 hour, dry to obtain modified quartz fiber, respectively add 40 parts of modified quartz fiber, 20 parts of TiO 2 , 5 copies of WO 3 , 5 copies of V 2 o 5 After mixing with 5 parts of hydroxymethylcellulose ammonium, put it into a kneader, add 80 parts of water, and stir for 1 hour at a speed of 100r / min to obtain a mixed slurry. After stirring, put the mixed slurry into the extrusion Extrude in the machine, dry the extruded green body at 50°C for 20 hours, and then calcinate at 150°C for 10 hours. The number is 100 mesh powder, mix 80 parts of the sieved powder with 5 parts of α-alumina whiskers, 20 parts of γ-alumina powder and 5 parts of clay, put it into t...

Embodiment 2

[0030] Configure titanate coupling agent solution:

[0031] Mix and stir the titanate coupling agent TC-2 of Tianchen Chemical and acetone according to the volume ratio of 1:100 to obtain the titanate coupling agent.

[0032] Immerse 100 parts of quartz fiber in 1515 parts of titanate coupling agent, after immersion treatment for 1-2h, dry to obtain modified quartz fiber, respectively add 50 parts of modified quartz fiber, 30 parts of TiO 2 , 10 copies of WO 3 , 10 copies of V 2 o 5 After mixing with 15 parts of hydroxypropyl methylcellulose ammonium, put it into a kneader, add 90 parts of methanol, and stir at a speed of 300r / min for 1 hour to obtain a mixed slurry. After stirring, put the mixed slurry into Extruded in an extruder, dried the extruded green body at 100°C for 10 hours, and then calcined at 300°C for 5 hours. After the calcination, the first green body was obtained, which was crushed and sieved Take the 200-mesh powder, mix 100 parts of the sieved powder wit...

Embodiment 3

[0034] Configure titanate coupling agent solution:

[0035] Mix and stir the titanate coupling agent TC-27 of Tianchen Chemical and acetone according to the volume ratio of 1:50 to obtain the titanate coupling agent.

[0036] Immerse 100 parts of quartz fiber in 550 parts of titanate coupling agent, after immersion treatment for 1.5h, dry to obtain modified quartz fiber, respectively add 45 parts of modified quartz fiber, 25 parts of TiO 2 , 8 copies of WO 3 , 7 copies of V 2 o 5 After mixing with 10 parts of epoxy resin, put it into a kneader, add 85 parts of ethanol, and stir at a speed of 200r / min for 1.5h to obtain a mixed slurry. After stirring, put the mixed slurry into an extruder Extrusion molding, drying the extruded embryo body at 80°C for 15 hours, and then calcining at 200°C for 7 hours after drying, the first embryo body is obtained after the calcination is completed, the first embryo body is crushed and sieved, and the mesh size is 180 mesh powder, mix 90 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average fiber length | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com