Catalyst for synthesizing Trioctyl/tridecylaklylamines and preparation method and application of catalyst

A technology of octadecyl tertiary amine and catalyst, which is applied in the field of organic synthesis, can solve the problems of increased production cost, increased catalyst consumption, and slow conversion of trioctyl tertiary amine, so as to avoid catalyst deactivation and reduce catalyst wear , to reduce the effect of exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0077] Embodiment 1-3: Catalyst for preparing long carbon chain aliphatic tertiary amine

[0078] 1. Raw material composition: see Table 1

[0079] Table 1: The proportioning of raw materials in embodiment 1-3

[0080] Example 1 Example 2 Example 3 Copper nitrate trihydrate Cu(NO 3 ) 2 ·3H 2 o

400 400 400 Nickel nitrate hexahydrate Ni(NO 3 ) 2 ·6H 2 o

150 100 100 Zinc nitrate nonahydrate Zn(NO 3 ) 2 ·6H 2 o

80 50 Iron nitrate nonahydrate Fe(NO 3 ) 2 9H 2 o

50 Magnesium nitrate hexahydrate Mg(NO 3 ) 2 ·6H 2 o

70 50 50 ionized water 1600+1000 1600+1000 1600+1000 activated clay 500 500 500 10% sodium carbonate adjust pH adjust pH adjust pH

[0081] 2. Preparation process

[0082] Taking the formula of Example 1 as an example, 400kg Cu(NO 3 ) 2 ·3H 2 O, 150kg Ni(NO 3 ) 2 ·6H 2 O, 80kg Zn(NO 3 ) 2 ·6H 2 O, 70kg Mg(NO 3 ) 2 ·6H 2 O was put in...

Embodiment 4

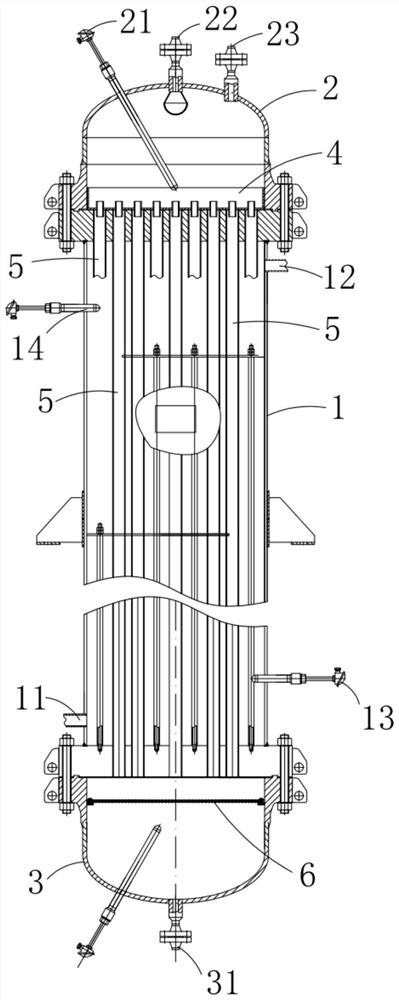

[0083] Embodiment 4: fixed bed reactor

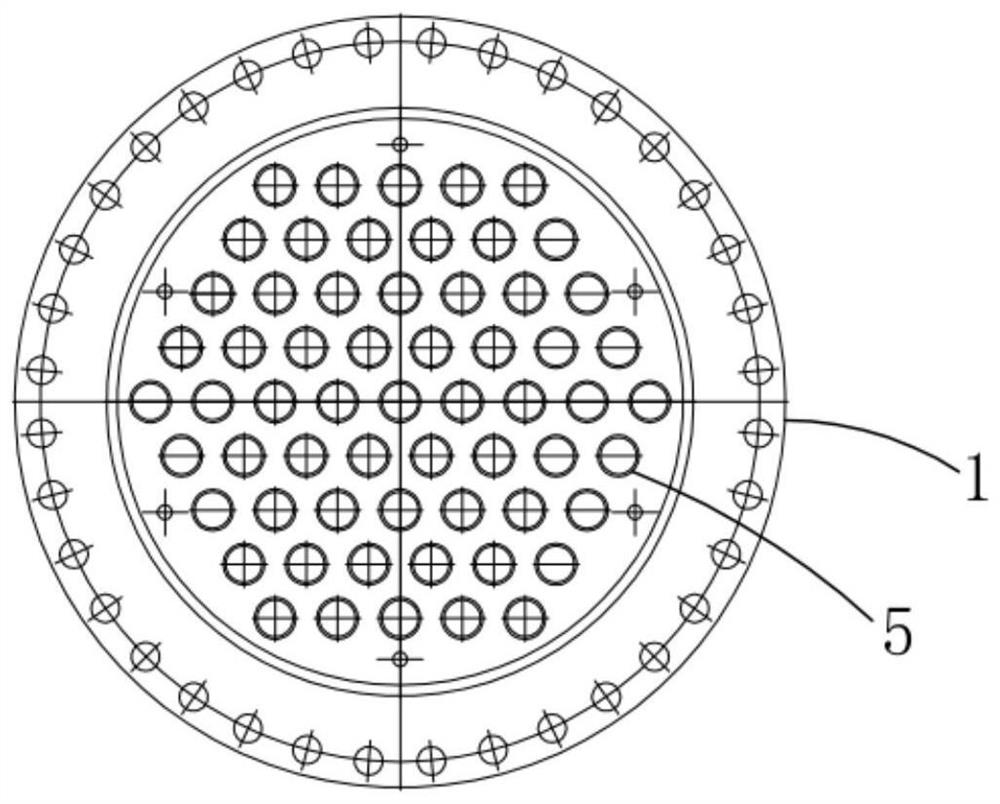

[0084] Such as Figures 1 to 3 As shown, the fixed bed reactor includes:

[0085] Housing 1, the lower side of the housing 1 is provided with a heat transfer oil inlet 11 and a bottom temperature measurement port 13, and the upper side is provided with a heat transfer oil outlet 12 and a heat transfer oil temperature measurement port 14;

[0086] The upper head 2, the upper head 2 is installed on the upper end of the housing 1, and it is provided with a top temperature measuring port 21, a feed port 22 and a hydrogen or nitrogen gas inlet 23;

[0087]The lower sealing head 3, the lower sealing head 3 is installed on the lower end of the housing 1, and a discharge port 31 is arranged on it, and it is characterized in that it also includes:

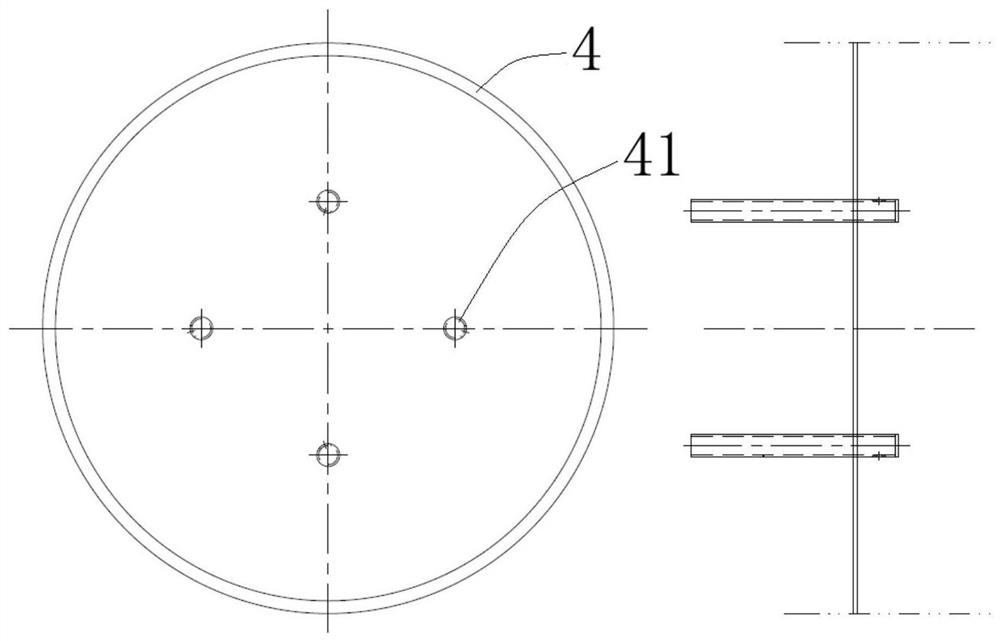

[0088] A static distributor 4, the static distributor 4 is arranged in the upper head 2, and the static distributor 4 is provided with several liquid outlet holes 41 communicating with the housing ...

Embodiment 5

[0093] Embodiment 5: the preparation of trioctyl decanyl tertiary amine

[0094] 1. A fixed bed filled with catalyst (prepared in Example 1, height 350cm) (filled as in Example 4, the same below) is gradually heated up to 280°C under a mixture of nitrogen and hydrogen (the volume of nitrogen and hydrogen is 3:1) , and maintain the temperature for reduction for 72 hours, then cool to 200°C for use.

[0095] 2. After replacing the mixed gas in the fixed bed with hydrogen, set the hydrogen pressure to 1.5Mpa, pump in preheated octadecyl alcohol and vaporized liquid ammonia, pump in octadecyl alcohol and liquid ammonia to preheat The molar ratio of alcohol to ammonia is 3:1. The gas-liquid mixture passing through the preheater enters the fixed bed reactor. The temperature of the fixed bed is controlled at 210-230°C and the space velocity is 0.8h. -1 , the material that comes out is condensed to the gas-liquid separation of the oil-water separator, the oil layer is distilled to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com