Antireflection coating liquid, preparation method thereof, antireflection coated glass and photovoltaic module

A coated glass and anti-reflection technology, which is applied in photovoltaic power generation, reflection/signal coatings, electrical components, etc., can solve the problem that the anti-fouling performance of the film surface has not been effectively improved, the difficulty of large-area coating production, and the anti-reflection of the film surface Reduce the efficiency and other problems, achieve excellent anti-fouling performance, low raw material and manufacturing costs, and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 sealing agent and preparation method thereof

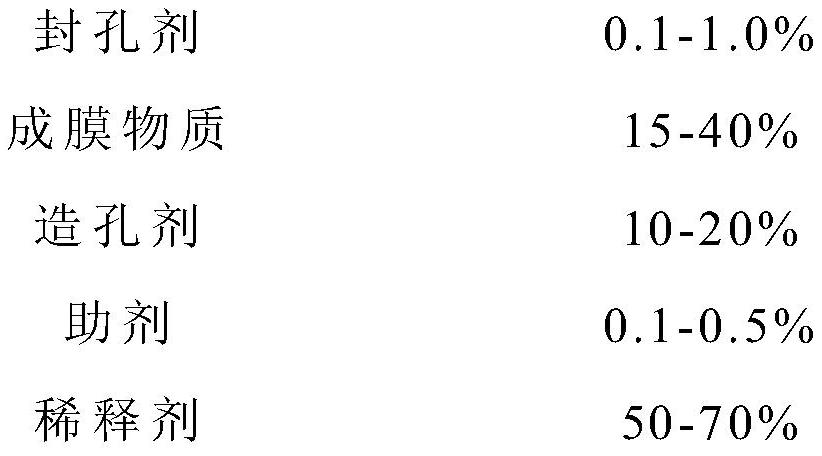

[0045] The sealing agent in the present embodiment comprises following components:

[0046]

[0047]

[0048] The hydrogen content of the low-hydrogen silicone oil in this example is 0.10%. The solvent is a mixed solvent of isopropanol and propylene glycol methyl ether acetate. Use isopropanol and propylene glycol methyl ether acetate with a higher boiling point, avoid using more toxic benzene solvents or acetone, and ensure that the boiling point of the mixed solvent in the reaction is higher than the reaction temperature, and the reactants and products can be dissolved in the solvent.

[0049] In some other embodiments, the hydrogen content of the low-hydrogen silicone oil is 0.1-1.0%; the solvent is an alcoholic solvent and / or a high boiling point solvent, wherein the alcoholic solvent is one of isopropanol, ethanol, and n-butanol one or more species. The high boiling point solvent is one or more of...

Embodiment 2

[0053] Embodiment 2 anti-reflection coating solution and preparation method thereof

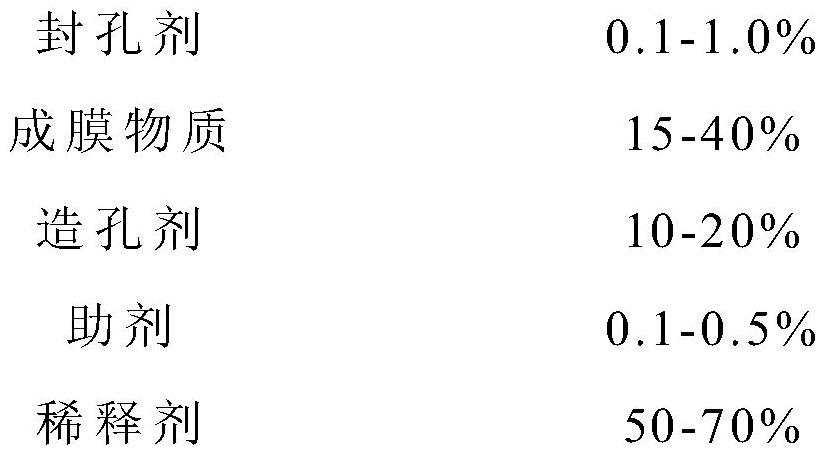

[0054] The anti-reflection coating solution in the present embodiment comprises following components:

[0055]

[0056] Concrete preparation method is as follows:

[0057] (1) Preparation method of film-forming substance

[0058] (1) Add 20g ethyl orthosilicate, 160g methyltriethoxysilane, 32g vinyltriethoxysilane, 61g water, 316g isopropanol into the reaction kettle, mix and stir evenly, add 0.08g hydrochloric acid solution , continue stirring.

[0059] In other embodiments, the silicon source is one or both of methyl orthosilicate and ethyl orthosilicate; the silane coupling agent is methyltriethoxysilane, methyltrimethoxysilane, ethylene Triethoxysilane, dimethyldiethoxysilane, phenyltrimethoxysilane, γ-glycidoxypropyltrimethoxysilane or γ-methacryloxypropyltrimethoxysilane Two or more; water is deionized water; catalyst is one or more of hydrochloric acid, acetic acid, nitric acid,...

Embodiment 3

[0068] Embodiment 3 sealing agent and preparation method thereof

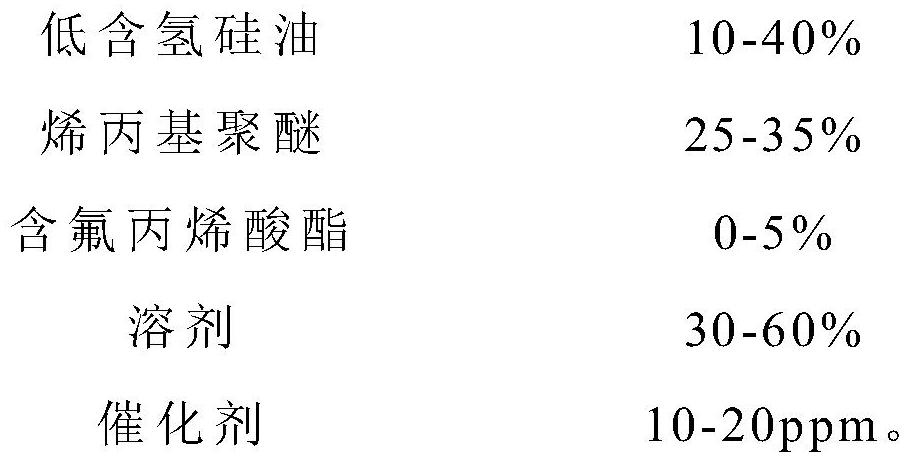

[0069] The sealing agent in the present embodiment comprises following components:

[0070]

[0071]

[0072] The hydrogen content of the low-hydrogen silicone oil in this example is 0.18%. The solvent is a mixed solvent of isopropanol and butyl acetate.

[0073] The preparation method of sealing agent in the present embodiment comprises the steps:

[0074] (1) Add 25g of isopropanol, 5g of butyl acetate and 36.91g of low-hydrogen silicone oil with a hydrogen content of 0.18% into a three-necked flask, and control the stirring speed at 90rpm, and pass nitrogen into the three-necked flask for 1 hour to replace the system in the air.

[0075] (2) The system was heated up to 100°C, and 33.17g of allyl polyethylene glycol methyl ether AEM-10 (molecular weight 498, pure EO structure) and 2.8g of Karstedt catalyst were mixed and added to a dropping funnel; 1.02g Add the hexafluorobutyl acrylate in another d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com