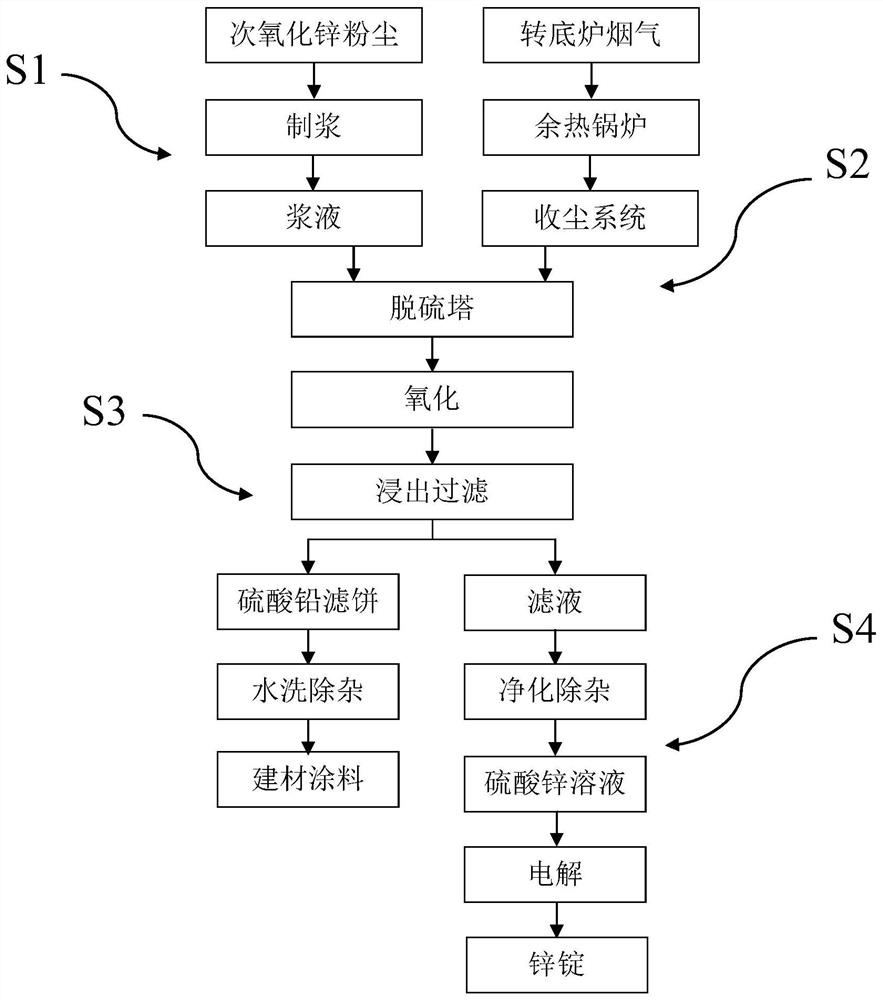

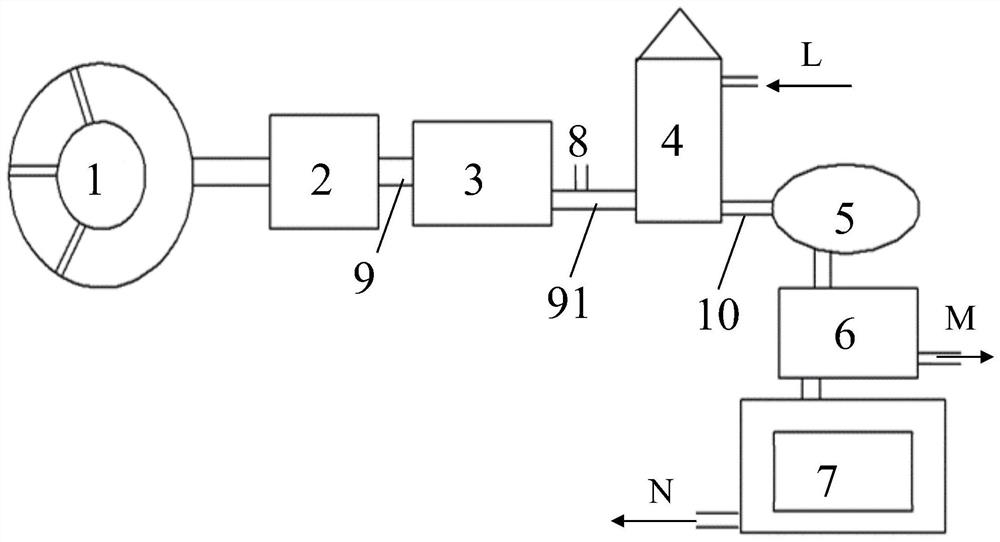

Treatment method and device for secondary zinc oxide dust

A treatment method and technology of secondary zinc oxide, applied in chemical instruments and methods, separation methods, inorganic chemistry and other directions, can solve the problems of occupying land, wasting valuable resources of zinc, lead and iron, and difficult to use leaching slag, reducing the The cost of flue gas treatment, the realization of resource utilization, and the remarkable effect of environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Prepare a slurry of subzinc oxide dust with a Zn content of 52.30%, a Pb content of 13.16%, and a TFe content of 2.12% and water at a ratio of 1:1, and add tartaric acid to adjust the pH to 4.3;

[0055] SO in rotary hearth furnace flue gas 2 The concentration is 1.7%, and the temperature drops to 33°C and enters the desulfurization tower; the slurry and the flue gas of the rotary hearth furnace are calculated according to the molar ratio (Zn+Pb) / (SO 2 )=1.5 into the desulfurization tower for desulfurization treatment to obtain mixed liquor after treatment, wherein the desulfurization rate of the flue gas from the rotary hearth furnace is 86.34%;

[0056] The mixed solution is sent to the oxidation tank, and air with a temperature of 60°C is passed through for oxidation treatment, and dilute sulfuric acid with a concentration of 38% is added for treatment, wherein the volume ratio of the mixed solution to dilute sulfuric acid is 100:4, and after 40 minutes of oxidation ...

Embodiment 2

[0059] Prepare a slurry of subzinc oxide dust with a Zn content of 53.88%, a Pb content of 14.87%, and a TFe content of 2.93% and water at a ratio of 1:1, and add tartaric acid to adjust the pH to 4.5;

[0060] SO in rotary hearth furnace flue gas 2 The concentration is 1.35%, and the temperature drops to 25°C and enters the desulfurization tower; the slurry and the flue gas of the rotary hearth furnace are calculated according to the molar ratio (Zn+Pb) / (SO 2 )=1.8 ratio is sent into the desulfurization tower, carries out desulfurization treatment, obtains mixed liquor after the treatment, wherein the desulfurization rate of the flue gas of the rotary hearth furnace is 92.56%;

[0061] The mixed solution is sent to the oxidation tank, and air with a temperature of 65°C is passed through for oxidation treatment, and dilute sulfuric acid with a concentration of 32% is added for treatment, wherein the volume ratio of the mixed solution to dilute sulfuric acid is 100:4. After 50 ...

Embodiment 3

[0064] Zinc oxide dust with a Zn content of 55.54%, a Pb content of 17.12%, and a TFe content of 3.4% was prepared into a slurry with water at a ratio of 1:1, and tartaric acid was added to adjust the pH to 6;

[0065] SO in rotary hearth furnace flue gas 2 The concentration is 1.5%, and the temperature drops to 30°C and enters the desulfurization tower; the slurry and the flue gas of the rotary hearth furnace are calculated according to the molar ratio (Zn+Pb) / (SO 2 )=2 into the desulfurization tower for desulfurization treatment to obtain mixed liquor after treatment, wherein the desulfurization rate of the flue gas from the rotary hearth furnace is 89.11%;

[0066] The mixed solution is sent to the oxidation tank, and air at a temperature of 70°C is passed through for oxidation treatment, and 28% dilute sulfuric acid is used for treatment, wherein the volume ratio of the mixed solution to dilute sulfuric acid is 100:8, and after oxidation treatment for 50 minutes, the filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com