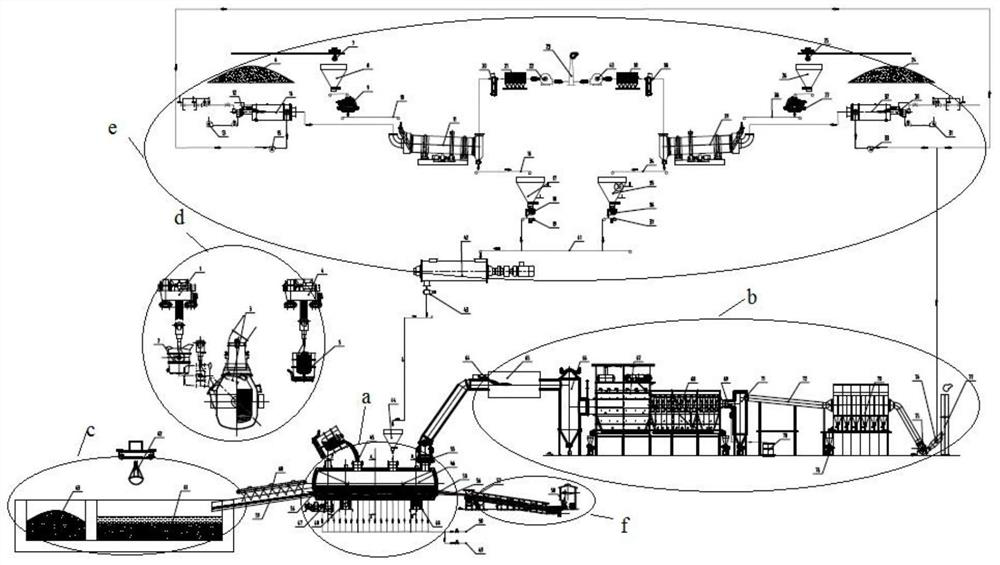

Device and method for synergistic quenching and tempering treatment of steel slag and nonferrous metal smelting slag

A non-ferrous metal, quenching and tempering technology, applied in the field of iron and steel metallurgy, can solve the problems of site construction and maintenance costs, less than 1%, secondary waste of resources, etc. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

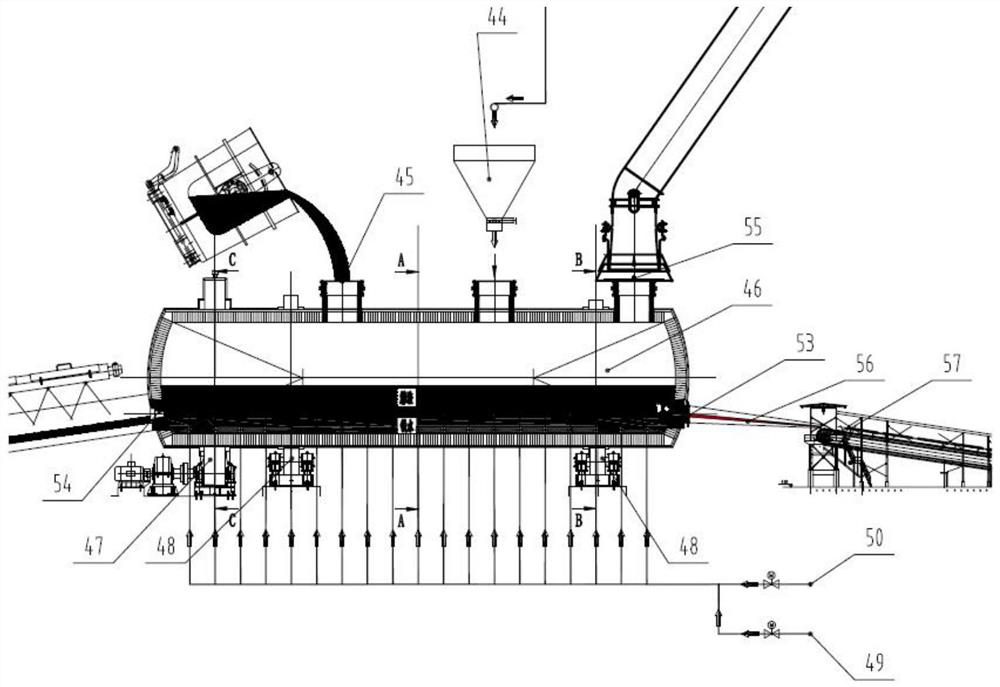

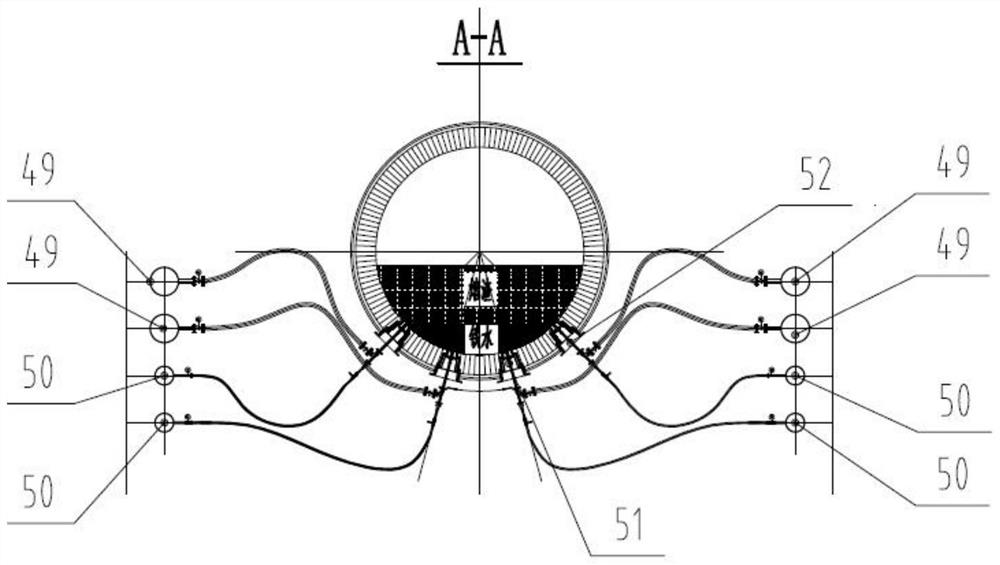

Embodiment 1

[0128] In this example, a steel plant has an annual output of 4 million tons of steel, an annual output of 400,000 tons of converter steel slag, and an average hourly slag discharge of 47.62 t / h. Originally, the hot stuffy slag method was used, and the slag utilization rate was about 20%. The above-mentioned method of synergistic conditioning and tempering treatment of steel slag and non-ferrous metal smelting slag, by adding copper slag and red mud as a conditioning agent, pouring liquid molten steel slag at 1550-1600 °C (enthalpy about 56kg standard coal / t-slag) In the quenching and tempering furnace, add the dried copper slag and red mud, and perform a 60-min quenching and tempering treatment. In the quenching and tempering process, the oxygen-enriched air is used as the carrier, and the coal powder is sprayed through the coal oxygen lance to reduce the iron oxides in the steel slag, copper slag and red mud. The high-temperature liquid molten iron (pig iron) after quenching...

Embodiment 2

[0149] In this embodiment, 400,000 tons of steel slag and 460,000 tons of red mud are processed annually, totaling 860,000 tons. The total iron content in steel slag is 20.88%, and the total iron content in red mud is 37.72%. ~1600°C) into liquid metal iron, and the yield of iron metal is 96.22%.

[0150] Table 6 shows the composition and treatment amount of steel slag and red mud conditioner.

[0151] Table 6 Steel slag and red mud conditioner composition (%) and treatment amount

[0152] raw material TF Mfe Fe 2 o 3

Fe 3 o 4

FeO CaO SiO 2

Al 2 o 3

MgO K 2 o

Na 2 o

steel slag 20.88 7.9 10 10.42 41.4 14.96 0.84 5.49 0.12 0.14 red mud 37.72 53.89 14.02 7.62 16.04 0.63 0.04 4.38 average composition 29.89 0.00 32.50 4.65 4.85 26.75 11.03 8.97 2.89 0.08 2.41 PCI 0.5 5 4 0.4

[0153] Continued Table 6 Steel slag and red mud conditioner compos...

Embodiment 3

[0169] The present embodiment processes 400,000 tons of steel slag and 460,000 tons of copper slag annually, totaling 860,000 tons. The steel slag has a total iron content of 20.88%, and copper slag has a total iron content of 41.93%. ~1600°C) into liquid metal iron, and the yield of iron metal is 95.98%.

[0170] Table 11 shows the composition and treatment amount of steel slag and copper slag conditioner.

[0171] Table 11 Steel slag and copper slag conditioning agent composition (%) and treatment capacity

[0172] raw material TF Mfe Fe 2 o 3

Fe 3 o 4

FeO CaO SiO 2

Al 2 o 3

MgO K 2 o

Na 2 o

steel slag 20.88 7.9 10 10.42 41.4 14.96 0.84 5.49 0.12 0.14 copper slag 41.93 0.64 3.96 7.28 42.74 3.84 29.79 3.92 1.04 0.77 0.44 average composition 32.14 0.34 5.79 8.55 27.71 21.31 22.89 2.49 3.11 0.47 0.30 PCI 0.5 5 4 0.4

[0173] Continued Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com