A kind of preparation method of catalyst for automobile exhaust gas and its product and application

A technology for automobile exhaust and catalysts, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as threats to health, poor anti-poisoning ability, and reduced catalytic activity, and achieve excellent processing capacity. , improve sulfur resistance, improve the effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

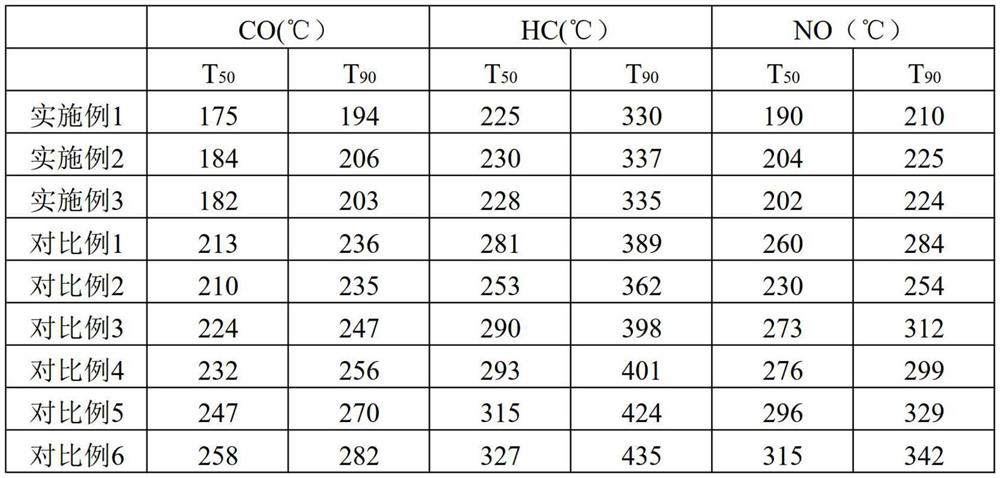

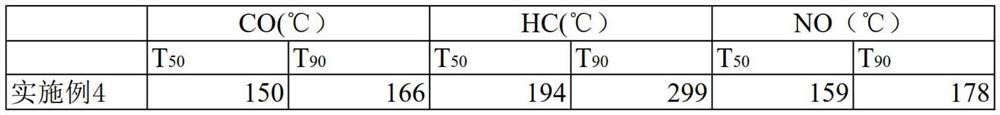

Embodiment 1

[0032] A kind of preparation method of the catalyst that automobile exhaust is used, described preparation method comprises the following steps:

[0033] (1) Immerse alumina particles with a diameter of 1 mm in 45 mL of a mixed aqueous solution containing magnesium nitrate and urea, heat-treat at 80° C. for 24 hours, filter, wash, then dry, and roast to obtain magnesium-modified alumina; The molar ratio of aluminum to magnesium nitrate is 18:1; the molar ratio of urea to magnesium nitrate is 9:1; the drying is at 120°C for 9 hours; the roasting is at 500°C for 6 hours;

[0034] (2) Take a certain amount of cerium nitrate, zirconium nitrate, yttrium nitrate and samarium nitrate by stoichiometric ratio to form a mixed solution, and use the mixed solution of ammonia and ammonium carbonate as a precipitant for precipitation, wherein the mol ratio of ammonia and ammonium carbonate 1:1, add the precipitant dropwise to the above solution, stir and keep the pH at 10, age for 22h, filt...

Embodiment 2

[0041] A kind of preparation method of the catalyst that automobile exhaust is used, described preparation method comprises the following steps:

[0042] (1) Immerse alumina particles with a diameter of 1 mm in 50 mL of a mixed aqueous solution containing magnesium nitrate and urea, heat-treat at 85° C. for 20 hours, filter, wash, then dry, and roast to obtain magnesium-modified alumina; The molar ratio of aluminum to magnesium nitrate is 20:1; the molar ratio of urea to magnesium nitrate is 8:1; the drying is at 140°C for 8 hours; the roasting is at 550°C for 4 hours;

[0043] (2) Take a certain amount of cerium nitrate, zirconium nitrate, yttrium nitrate and samarium nitrate by stoichiometric ratio to form a mixed solution, and use the mixed solution of ammonia and ammonium carbonate as a precipitant for precipitation, wherein the mol ratio of ammonia and ammonium carbonate 1:1, add the precipitant dropwise to the above solution, stir and keep the pH at 9, age for 24h, filte...

Embodiment 3

[0050] A kind of preparation method of the catalyst that automobile exhaust is used, described preparation method comprises the following steps:

[0051] (1) Immerse alumina particles with a diameter of 1mm in 40mL of a mixed aqueous solution containing magnesium nitrate and urea, heat-treat at 70°C for 26 hours, filter, wash, then dry, and roast to obtain magnesium-modified alumina; The molar ratio of aluminum to magnesium nitrate is 15:1; the molar ratio of urea to magnesium nitrate is 10:1; the drying is at 110°C for 10 hours; the roasting is at 440°C for 8 hours;

[0052] (2) Take a certain amount of cerium nitrate, zirconium nitrate, yttrium nitrate and samarium nitrate by stoichiometric ratio to form a mixed solution, and use the mixed solution of ammonia and ammonium carbonate as a precipitant for precipitation, wherein the mol ratio of ammonia and ammonium carbonate 1:1, add the precipitating agent dropwise to the above solution, stir and keep the pH at 10, age for 20h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com