Preparation method of glycine complex zinc salt premix and production system thereof

A technology of glycine complex and production system, which is applied in the field of preparation of glycine complex zinc salt premix, can solve the problems of low absorption utilization rate, easy agglomeration, complex production process, etc., and achieve low production cost, no Easy to agglomerate and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

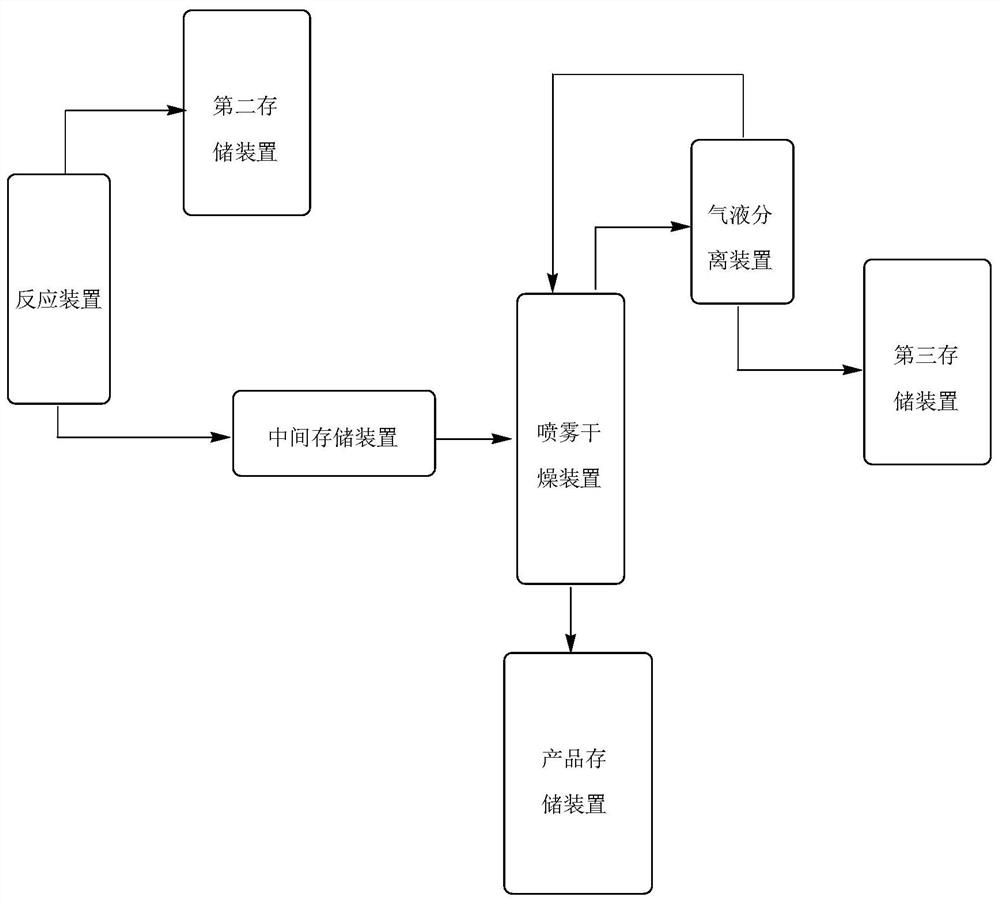

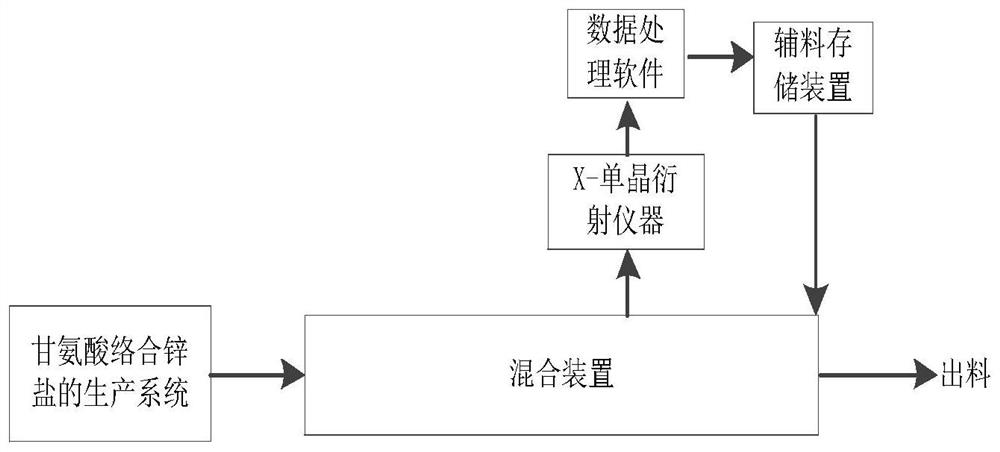

[0065] The invention provides a kind of glycine complex zinc salt premix production system, combining figure 1 and figure 2 , the production system as figure 2 shown, including figure 1 The shown glycine complex zinc salt production system, X-ray single crystal diffraction instrument, data processing software, auxiliary material storage device and mixing device.

[0066] The glycine complex zinc salt produced by the glycine complex zinc salt production system is detected by the X-ray single crystal diffraction instrument to obtain the detection data, and then the data is matched with the data processing software. After matching, the data processing software determines the glycine complex zinc The type of salt, and then order the auxiliary material storage device to execute the command of feeding, and finally mix in the mixing device to obtain the glycine complex zinc salt premix.

Embodiment 2

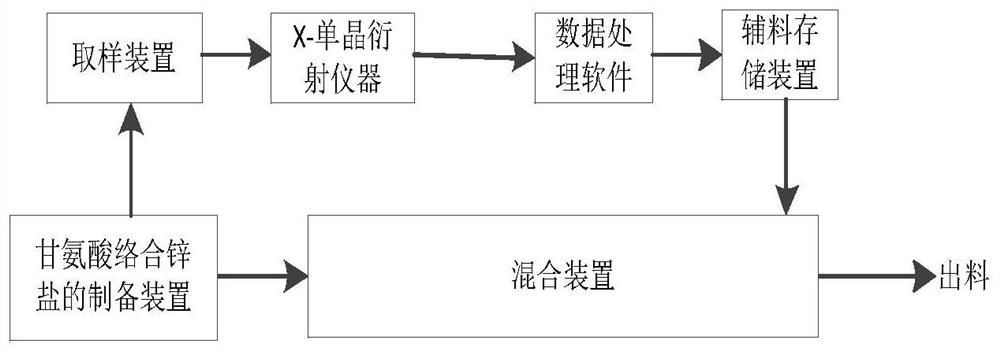

[0068] The present invention also provides a kind of glycine complex zinc salt premix production system, combining image 3 , this production system is to increase a sampling device on the basis of embodiment 1 and carry out sampling, convenient detection, sampling device is connected to glycine complex zinc salt production system, then is connected with X-ray single crystal diffraction instrument and detects, then with The data processing software is connected to perform data matching processing and give an order, and the auxiliary material storage device receives the order and executes the feeding to the mixing device for mixing to obtain a glycine complex zinc salt premix.

Embodiment 3

[0070] (1) Complexation reaction of glycine and zinc salt

[0071] In the reactor of 1000L, add the glycine crystal (2000 moles) of 151.66kg content 99wt% and the deionized water of 300kg, be warming up to 75 ℃ then, add the heptahydrate zinc sulfate 580.93kg (2000kg) of content 99wt% under the state of stirring mol), stir to dissolve completely, immediately heat up to 95° C., and keep warm for 2.0 hours to obtain an aqueous solution of glycine complex zinc salt. The concentration of glycine complex zinc salt in this aqueous solution is 45.62 wt%.

[0072] (2) Spray drying treatment of glycine complex zinc salt

[0073] The glycine complex zinc salt aqueous solution obtained above is subjected to decompression concentration treatment in the reactor, the condensed water is circulated to the next batch of production water, and the glycine complex zinc salt aqueous solution is concentrated until the concentration of the glycine complex zinc salt is about 80wt%. And the concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com