Low-temperature sulfur-tolerant denitration catalyst and preparation method and application thereof

A denitrification catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high preparation cost of low-temperature water resistance and sulfur resistance, high low temperature activity, low water resistance and sulfur resistance, etc. , achieve good thermal stability and mechanical properties, good low-temperature activity and sulfur resistance, improve dispersion and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

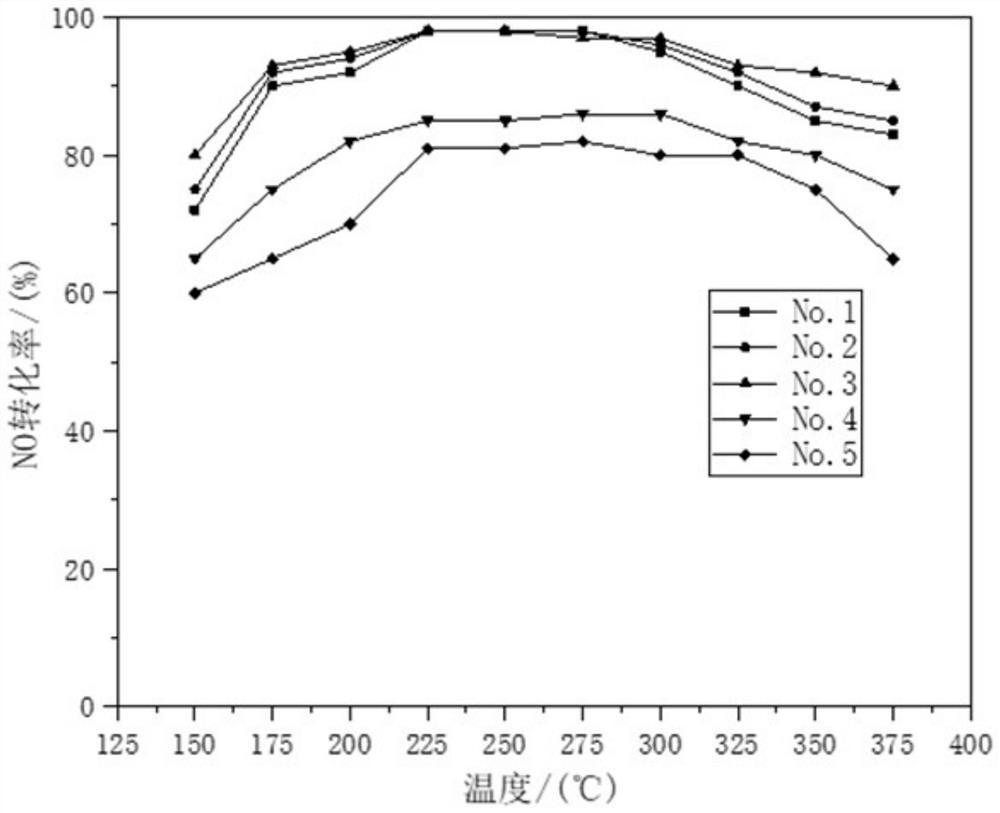

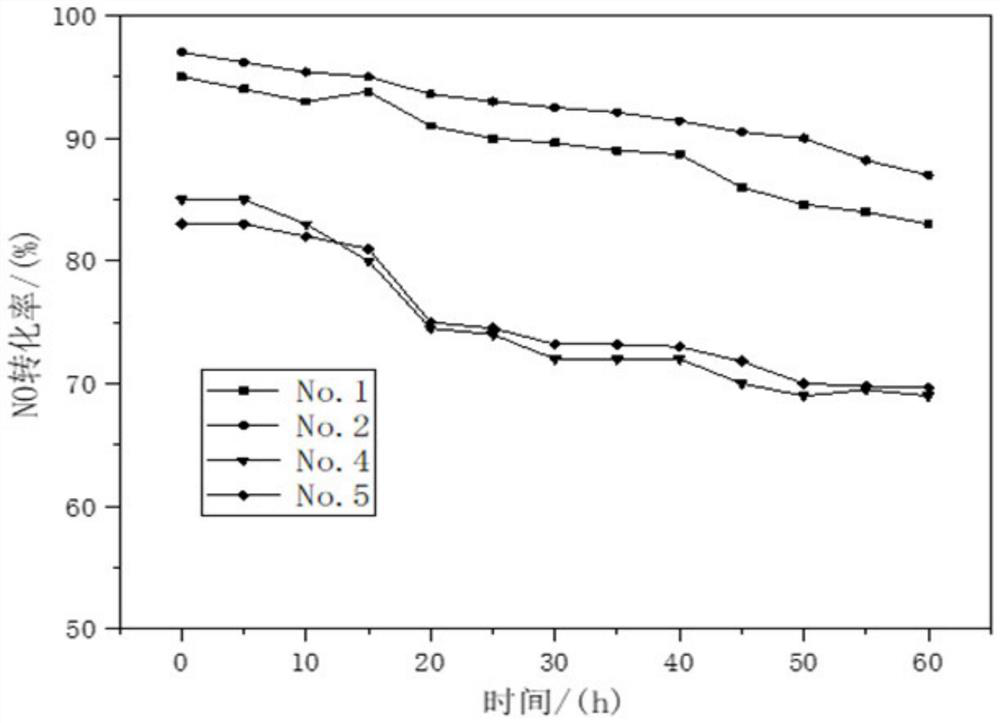

Examples

Embodiment 1

[0034] (1) The carrier is prepared by co-precipitation method, and 6.34g Zr(NO 3 ) 4 ·5H 2 O, 2.75gFe(NO 3 ) 3 9H 2 O and 5.34g of metatitanic acid powder were dissolved in water and mixed evenly, then according to Fe 3+ with Zr 4+ Add 1-2 times of the theoretical amount of precipitant required for complete precipitation of ions, including ammonia water, to form a precipitate. After stirring and aging at 40° C. for 4 h, the product was filtered and washed to form a carrier precursor.

[0035] (2) The perovskite catalyst was prepared by the chemical complexation method, and 43.3g La(NO 3 ) 2 ·6H 2 O, 2.9gNi(NO 3 ) 2 ·6H 2 O, 0.291gCo(NO 3 ) 2 ·6H 2 O and 22.34gMn(NO 3 ) 2 4H 2 O was dissolved in water, and 53.46g of ammonium citrate complexing agent was added to form a uniform mixed solution. Then add the carrier precursor obtained in step (1), mix to form a uniform gel, dry the gel at 100°C for 12 hours, and then bake the gel at 350°C for 4 hours to obtain t...

Embodiment 2

[0039] (1) The carrier is prepared by co-precipitation method, and 3.972g Zr(NO 3 ) 4 ·5H 2 O, 1.725gFe(NO 3 ) 3 9H 2 O and 3.349g metatitanic acid powder were dissolved in water and mixed evenly, then according to Fe 3+ with Zr 4+ Add 1-2 times of the theoretical amount of precipitant required for complete precipitation of ions, including ammonia water, to form a precipitate. After stirring and aging at 70° C. for 4 h, the product was filtered and washed to form a carrier precursor.

[0040] (2) The perovskite catalyst was prepared by the chemical complexation method, and 43.3g La(NO 3 ) 2 ·6H 2 O, 5.82gNi(NO 3 ) 2 ·6H 2 O, 0.873gCo(NO 3 ) 2 ·6H 2 O and 19.327gMn(NO 3 ) 2 4H 2 O was dissolved in water, and 53.46g of ammonium citrate complexing agent was added to form a uniform mixed solution. Then add the carrier precursor obtained in step (1), mix to form a uniform gel, dry the gel at 100°C for 12 hours, and then bake the gel at 350°C for 4 hours to obtain...

Embodiment 3

[0044] (1) The carrier is prepared by co-precipitation method, and 12.38g Zr(NO 3 ) 4 ·5H 2 O, 5.374gFe(NO 3 ) 3 9H 2 O and 10.44g metatitanic acid powder were dissolved in water and mixed evenly, then according to Fe 3+ with Zr 4+ Add 1-2 times of the theoretical amount of precipitant required for complete precipitation of ions, including ammonia water, to form a precipitate. After stirring and aging at 80° C. for 4 h, the product was filtered and washed to form a carrier precursor.

[0045] (2) The perovskite catalyst was prepared by the chemical complexation method, and 43.3g La(NO 3 ) 2 ·6H 2 O, 8.72gNi(NO 3 ) 2 ·6H 2 O, 1.164gCo(NO 3 ) 2 ·6H 2 O and 16.57gMn(NO 3 ) 2 4H 2 O was dissolved in water, and 53.46g of ammonium citrate complexing agent was added to form a uniform mixed solution. Then add the carrier precursor obtained in step (1), mix to form a uniform gel, dry the gel at 100°C for 12 hours, and then bake it at 550°C for 4 hours to obtain the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com