Antibacterial gel material for dental restoration, and preparation method thereof

A gel material and oral restoration technology, which is applied in the field of medical materials, can solve problems such as lack, and achieve the effects of preventing gel loss, improving acid resistance, and strong acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

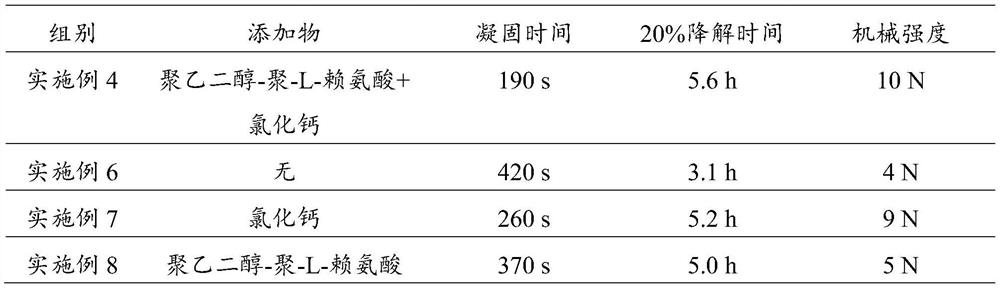

Examples

Embodiment 1

[0064] Preparation of hydroxypropyl chitosan

[0065] Add 20g chitosan in the three-neck flask, 50mL mass fraction is 15% NaOH solution and Virahol 200mL, stir and alkalize at room temperature for 1h, then add 45mL mass fraction as 10% tetramethylammonium hydroxide solution and 200mL of propylene oxide, stirred at room temperature for 30min, heated to 60°C, refluxed and stirred for 8h, neutralized with hydrochloric acid aqueous solution with a volume ratio of 1:1 to pH = 7, precipitated the product with acetone, and obtained the crude product by suction filtration . The obtained crude product is purified by repeated dissolution and precipitation. Firstly, the obtained crude product is dissolved in deionized water, and then excessive ethanol is poured into it to precipitate the product, filtered, and the purification steps are repeated 2 to 3 times, and dried to obtain hydroxyl Propyl chitosan.

Embodiment 2

[0067] Preparation of Carboxymethylated Hydroxypropyl Chitosan

[0068] Weigh 10g of the hydroxypropyl chitosan prepared in Example 1 and dissolve it in an appropriate amount of distilled water. After stirring at room temperature for 0.5h, add 2 times the molar amount of NaOH solution with a mass fraction of 35%. After stirring for 2h to alkalize, add 150ml of iso After propanol is fully stirred, slowly add chloroacetic acid aqueous solution in batches or dropwise. The molar mass of chloroacetic acid aqueous solution is 4 times that of hydroxypropyl chitosan. , cooled to room temperature, poured out the reaction solution, and removed small molecule impurities by dialysis with a dialysis membrane with a molecular weight of 3Kda, then adjusted the pH to neutral, precipitated and purified the product with acetone, and obtained carboxymethylated hydroxypropyl chitosan sugar.

Embodiment 3

[0070] Preparation of polyethylene glycol-poly-L-lysine

[0071] React 1g of L-lysine and 20% excess triphosgene in 20mL of tetrahydrofuran solvent at 50°C until clear and then react for 1h to transform into the structure of L-lysine-N-carboxy-anhydride. The obtained L-lysine-N-carboxy-anhydride monomer crude product was recrystallized and purified three times from tetrahydrofuran and n-hexane to obtain the final product for use.

[0072] 2g of monomethoxy polyethylene glycol primary amine (Mn=2000g mol -1) in a Schlenk bottle at 50°C in an oil bath for about 6 hours, and then cooled to room temperature; the prepared L-lysine-N-carboxy-cyclic anhydride was dissolved in dry dimethylformamide, and then extracted with a syringe Transfer to Schlenk bottle and react under nitrogen protection and room temperature; Utilize infrared spectrometer to confirm that after reaction is finished, get a small amount of sample and be mixed with 5mg / mL and carry out SEC / LLS (size exclusion chro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com